Precision Metal Units for Hydroelectric Power Plant Fabrication Service

Introduction to Hydroelectric Power Units

Hydroelectric power plants have long been a cornerstone of renewable energy, converting the kinetic energy of flowing water into electrical power that supports local communities and entire regions. The efficiency and reliability of these plants depend on the precision and quality of the critical components within the hydroelectric power units. High-performance metals and superalloys are essential for fabricating these components, which must withstand demanding operating conditions, including significant wear, corrosion, and mechanical stress.

Hydroelectric power units comprise various mechanical systems, including turbines, pump systems, and control modules, all constructed from high-strength materials to ensure durability and continuous operation. Neway Precision Works Ltd plays a crucial role in fabricating these precision metal units, utilizing advanced manufacturing processes to create components that meet the rigorous standards required by the renewable energy industry.

Typical Superalloys Used in Hydroelectric Power Unit Manufacturing

Hydroelectric power units require materials that possess exceptional mechanical properties, including strength, corrosion resistance, and the ability to withstand high-pressure environments. Superalloys, renowned for their high-performance characteristics, are ideal for components in hydroelectric power units. These alloys, including Inconel, Hastelloy, and Nimonic, each offer unique properties that make them well-suited for hydroelectric applications.

Inconel Alloys: Renowned for their exceptional resistance to oxidation and corrosion, Inconel alloys are well-suited for components subjected to fluctuating temperatures and pressure levels. They offer superior strength and stability, which are critical in ensuring the longevity of hydroelectric power units.

Hastelloy Alloys: These alloys are often used in corrosive environments due to their remarkable corrosion resistance. Components made from Hastelloy alloys maintain integrity even in highly aggressive operating conditions, making them suitable for parts in contact with water and other fluids.

Nimonic Alloys: Nimonic alloys are nickel-based and have high temperature and corrosion resistance, making them an excellent choice for turbine blades and other high-stress parts within hydroelectric systems.

Using these superalloys in hydroelectric power units ensures reliability, durability, and minimal downtime, contributing to the overall efficiency of hydroelectric power plants. The choice of materials is crucial to the performance of the power units, and the superalloys used by Neway Precision Works Ltd are specifically tailored to meet the unique demands of the renewable energy sector.

Manufacturing Process and Equipment of Hydroelectric Power Units

Producing hydroelectric power units involves several sophisticated manufacturing processes, each carefully chosen based on the specific component requirements and intended application. The following are some of the critical manufacturing processes used by Neway Precision Works Ltd:

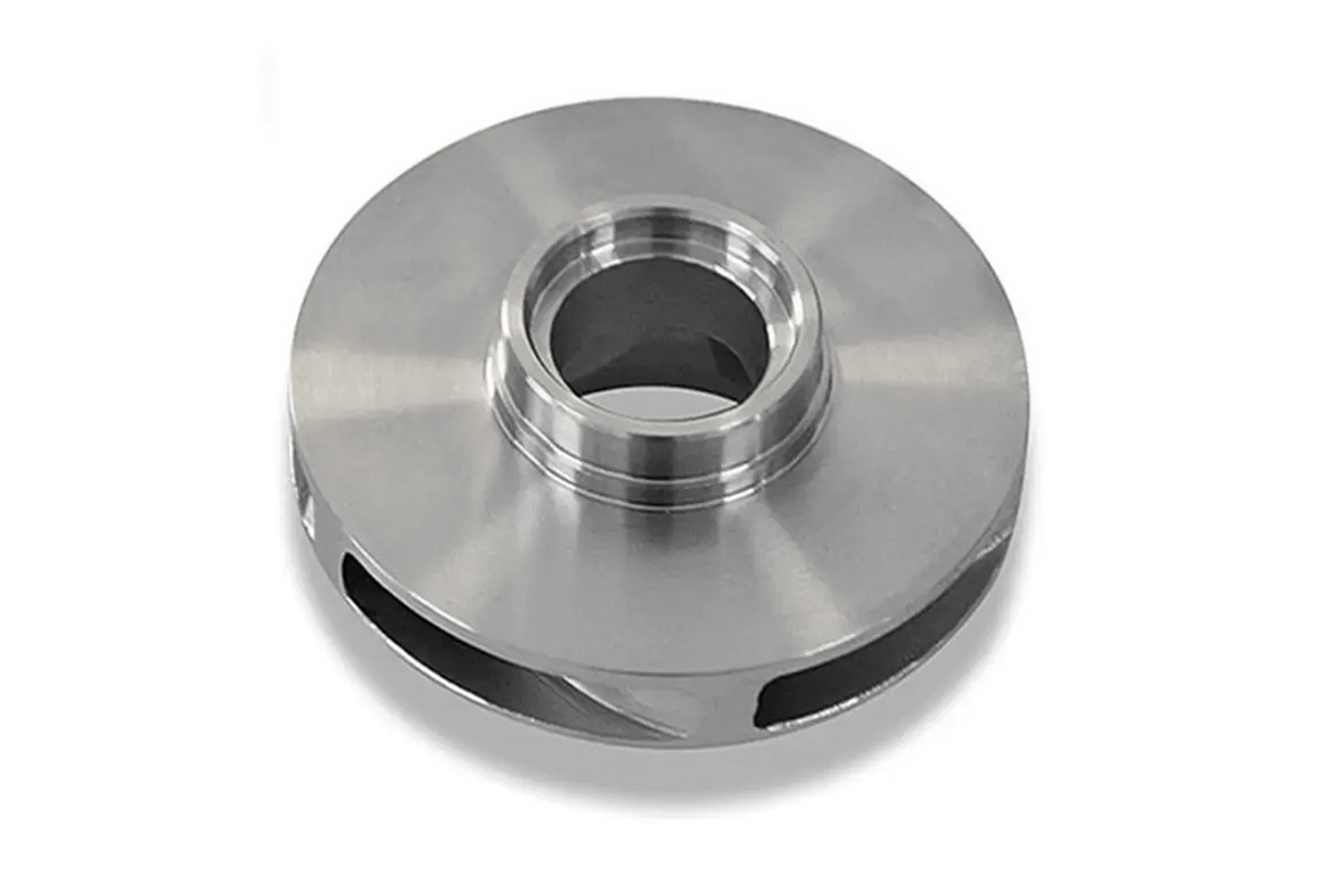

Vacuum Investment Casting: This process precisely fabricates high-performance superalloy components. Vacuum investment casting ensures minimal contamination and a uniform microstructure, which is crucial for the integrity and mechanical strength of critical hydroelectric components, such as turbine blades and pump impellers.

Single Crystal Casting: Single-crystal casting technology is applied to parts that require enhanced thermal fatigue and creep resistance. It is essential for turbine blades operating under high-stress conditions within hydroelectric systems. The absence of grain boundaries in single-crystal components significantly improves their mechanical properties.

Equiaxed Crystal Casting: Equiaxed Crystal Casting manufactures components requiring uniform properties in all directions. This process enables the production of durable parts with excellent thermal shock and fatigue resistance, thereby contributing to the overall robustness of hydroelectric power units.

Powder Metallurgy: This technique produces turbine discs and other components that benefit from improved microstructural consistency and mechanical properties. Powder metallurgy enables the manufacturing of complex shapes with minimal material waste, enhancing efficiency.

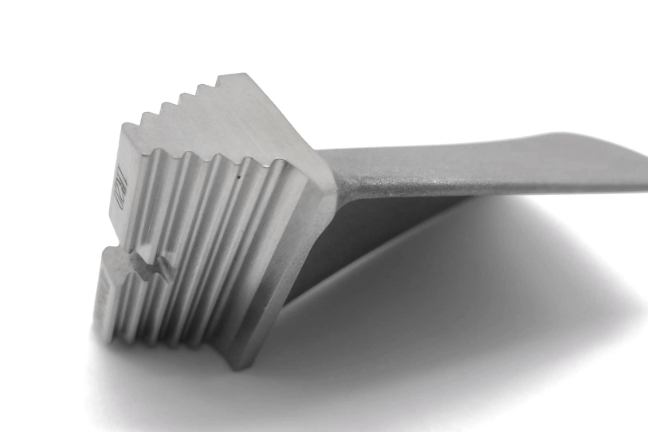

Superalloy Forging: Forging is utilized to create components that require high strength and flexibility. Superalloy forging shapes parts at high temperatures, enhancing grain structure and overall performance.

Superalloy CNC Machining: CNC machining enables the achievement of tight tolerances and complex geometries. This process is crucial for producing components such as valve housings, shafts, and nozzles that require high precision and consistency.

Superalloy Additive Manufacturing: Utilizing additive manufacturing techniques, such as Selective Laser Melting (SLM), enables Neway to create parts with complex internal features and high performance. Additive manufacturing is particularly beneficial in prototyping and rapid production runs.

Testing Methods and Equipment in Hydroelectric Power Units QC

To ensure that all components meet the rigorous quality standards required for hydroelectric power plants, thorough testing is conducted at various stages of the production process. Quality control (QC) measures are crucial for verifying the mechanical properties, dimensional accuracy, and overall integrity of components.

Ultrasonic Testing

Ultrasonic testing is a non-destructive method to detect internal defects in castings and forged components. It helps ensure that no hidden flaws could compromise the performance of hydroelectric power units. This method is useful for verifying internal integrity in critical components.

X-ray Inspection

X-ray inspection is employed to evaluate the internal structure of cast components, ensuring no voids or inclusions could lead to mechanical failures. This method provides essential insights for detecting internal inconsistencies that might compromise operational safety.

Scanning Electron Microscope (SEM) Analysis

SEM analysis is used for detailed surface examination, enabling a thorough assessment of microstructure and detection of potential defects. SEM is crucial for understanding microstructural integrity and identifying any inconsistencies that may affect durability.

Tensile Testing

Mechanical property testing, such as tensile strength and elongation testing, ensures that components meet the required strength and flexibility standards. Tensile testing verifies the material's strength and flexibility, which is essential for handling dynamic stresses in hydroelectric applications.

Creep and Fatigue Testing

Creep and fatigue testing is critical for assessing the long-term performance of components subjected to high-stress conditions, such as turbine blades in hydroelectric power units. These tests evaluate endurance under prolonged stress, ensuring components maintain reliability over extended periods.

Industries and Applications of Hydroelectric Power Units

Hydroelectric power units are primarily used in the renewable energy sector, providing a sustainable power source for various applications. The primary industries that benefit from hydroelectric power units include:

Power Generation: Hydroelectric power units are a significant component of renewable energy infrastructure, contributing significantly to the global power supply.

Water Management Systems: Components used in hydroelectric power units also apply in water management systems, such as pumps and control units, which help regulate water flow and pressure.

Energy Storage Solutions: Pumped-storage hydroelectric systems use precision metal components to store and generate energy, balancing supply and demand in energy grids.

The versatility of hydroelectric power units extends beyond power generation, and the precision metal components produced by Neway enable these systems to operate efficiently and reliably across various applications.

Typical Post-Process of Hydroelectric Power Units

Post-processing is a crucial stage in the manufacturing of hydroelectric power units, as it enhances the properties of the components, ensuring they can withstand the challenging operating conditions they will face. The typical post-processing methods used by Neway include:

Heat Treatment: Heat treatment is applied to enhance the mechanical properties of components, including hardness, toughness, and fatigue resistance. This process also relieves internal stresses that may have developed during the casting or forging process.

Hot Isostatic Pressing (HIP): HIP is used to eliminate porosity and improve the density of superalloy components, enhancing their mechanical strength and fatigue resistance.

Superalloy Welding: Welding is used to join complex assemblies or repair components. Superalloy welding techniques ensure strong, defect-free joints that maintain the integrity of the hydroelectric power units.

Thermal Barrier Coating (TBC): TBC is applied to protect components from high temperatures and corrosion. This coating extends the life of parts such as turbine blades exposed to extreme thermal conditions.

Electrical Discharge Machining (EDM): EDM is used for the final precision machining of hard alloys, enabling intricate geometries and tight tolerances that are challenging to achieve with conventional machining methods.

Rapid Prototyping and Verification of Hydroelectric Power Units

The use of rapid prototyping techniques is a critical factor in the development of hydroelectric power units. It enables the rapid fabrication and evaluation of prototype components, significantly reducing the lead time for product development and allowing engineers to make swift design adjustments.

Rapid Prototyping Process

Superalloy 3D printing, such as Selective Laser Melting (SLM) and CNC machining, produces prototype components for hydroelectric power units. These methods can produce parts with complex geometries, allowing for functional testing and evaluation.

Importance of Verifying Samples

Verification is crucial in ensuring that prototype components meet the required performance criteria. Testing prototypes under actual operating conditions can identify and resolve potential design issues before moving into full-scale production. It saves time and reduces production costs by preventing defects and minimizing the need for rework.

Advanced Design and Engineering in Hydroelectric Power Units

One of the core aspects of producing effective hydroelectric power units is integrating advanced design and engineering principles into the manufacturing process. Each component must be meticulously designed to perform its specific function efficiently and reliably, with considerations for high pressures, fluctuating temperatures, and mechanical forces.

Design Optimization: Advanced design techniques are employed to create components that maximize energy conversion efficiency and minimize resistance and wear. Computational Fluid Dynamics (CFD) simulations often predict and enhance fluid flow characteristics within turbine blades and pumps. These simulations help optimize the water flow for energy generation, reducing energy loss and improving system efficiency.

Material Engineering: The success of hydroelectric power units largely depends on the proper selection and engineering of materials. Engineers at Neway collaborate closely with metallurgists to tailor superalloy compositions to meet the specific needs of each component, ensuring optimal properties such as strength, corrosion resistance, and fatigue life. Customizing alloy compositions can significantly improve the component's ability to withstand harsh operational conditions.

Finite Element Analysis (FEA): FEA is another powerful tool for predicting the behavior of components under stress and load. This analysis helps identify potential points of failure and modify designs accordingly to increase durability. FEA is especially useful for turbine blades, where minimizing material fatigue and crack initiation is crucial over a long service life.

Environmental and Economic Benefits of Hydroelectric Power Units

Hydroelectric power units not only contribute to the generation of renewable energy but also offer significant environmental and economic advantages. By generating power from flowing water, these units do not emit the harmful greenhouse gases that fossil fuel-based energy sources do. The environmental benefits include reduced air pollution, which contributes to improved public health and enhanced conservation efforts.

From an economic perspective, hydroelectric power units are cost-effective in the long run. While the initial capital investment for constructing a hydroelectric power plant may be high, the subsequent operational costs are relatively low. The fuel—water—is naturally replenished, making the energy generation process sustainable and cost-efficient. Neway's precision-manufactured components are engineered for durability, minimizing maintenance needs and ensuring long service intervals, which further contribute to economic benefits.

Hydroelectric power units also play a crucial role in energy security. Unlike other renewable energy sources, such as solar or wind, hydroelectric power can provide consistent energy output independent of weather conditions. This reliability makes hydroelectric power an integral part of the energy mix for countries seeking to enhance their energy independence.

Challenges in Hydroelectric Power Unit Manufacturing

While hydroelectric power units offer numerous benefits, their production presents challenges that require a high degree of engineering expertise and precision manufacturing capabilities.

Material Complexity: The superalloys used in hydroelectric components are difficult to machine due to their hardness and toughness. Specialized equipment, such as EDM and 5-axis CNC machining centers, are required to shape these materials accurately without compromising their properties.

Maintaining Dimensional Tolerances: Many components in hydroelectric power units must operate together seamlessly, making it essential to maintain tight dimensional tolerances. Achieving such precision in casting, forging, and machining requires careful process control and expertise in post-processing techniques such as heat treatment and Hot Isostatic Pressing (HIP).

Environmental Exposure: The components must resist mechanical stress and exposure to water, which can have varying chemical compositions that may be corrosive. Material selection and surface treatment methods are critical to the success of hydroelectric power units.

Minimizing Downtime: Hydroelectric power plants typically operate continuously, so any failure in a critical component can result in significant disruptions to the energy supply. It necessitates a focus on durability and reliability in every stage of the manufacturing process, from material selection to final post-processing.

FAQs

- What are the most common superalloys used in hydroelectric power unit components?

- How does vacuum investment casting enhance component performance?

- What quality control measures are used to ensure the reliability of hydroelectric power units?

- How does rapid prototyping contribute to the development of hydroelectric power components?