Boosting Alloy Strength with Post-Processing Techniques

Introduction

Neway Precision Works Ltd. is a leading provider of high-performance superalloy components for industries that demand resilience and strength, including aerospace, power generation, and oil and gas. Superalloys, known for their exceptional mechanical properties, are designed to perform under extreme conditions, resisting high temperatures, oxidation, and corrosion. However, these alloys' high-stress environments also require enhancements beyond their base properties. It is where post-processing techniques come in, providing superalloy parts with the durability, precision, and strength needed for critical applications.

Post-processing plays a crucial role in enhancing the overall strength of superalloy parts. Techniques such as Hot Isostatic Pressing (HIP), heat treatment, and various surface and mechanical strengthening processes improve the alloy's mechanical properties, eliminate internal defects, and protect against environmental wear. This blog will examine how these post-processing methods operate, their distinct advantages, and their significance in applications that rely on them.

Why Post-Processing is Essential for Superalloy Parts

Understanding Superalloy Requirements

Superalloys comprise nickel, cobalt, or iron-based alloys designed to withstand high stress and maintain structural integrity at temperatures approaching 1000°C. These alloys are crucial in applications such as jet engines, power plant turbines, and industrial chemical processing, where materials are subjected to intense thermal, mechanical, and chemical stresses. Despite their robust properties, casting and forging alone can leave microstructural flaws, residual stresses, and surface imperfections that post-processing must address to meet industry standards.

The Role of Post-Processing

Post-processing techniques help alleviate some of the inherent limitations of raw superalloy parts. For example, casting may leave microscopic voids, which weaken the alloy's structure, whereas forging can create residual stresses that reduce the alloy's fatigue resistance. Post-processing treatments mitigate these issues by refining the alloy's microstructure, relieving internal stresses, and adding protective coatings. The result is a superalloy part with optimized durability, strength, and reliability, critical for components exposed to high-stress environments.

Key Benefits

Post-processing offers several benefits:

Enhanced Strength: Techniques such as HIP and heat treatment improve the structural integrity and load-bearing capacity of superalloy parts.

Fatigue Resistance: Processes such as shot peening increase fatigue resistance, allowing parts to withstand repetitive stresses without premature failure.

Corrosion and Oxidation Protection: Surface treatments, such as thermal barrier coatings, shield parts from environmental degradation, which can compromise material integrity over time, particularly in corrosive or high-temperature environments.

Essential Post-Processing Techniques for Boosting Superalloy Strength

Neway employs a suite of post-processing methods to optimize the performance of superalloy components. Each technique targets enhancements to ensure the part can withstand its intended application environment. Below, we'll explore each technique and how it contributes to boosting the strength of superalloy parts:

Hot Isostatic Pressing (HIP): This process densifies and eliminates internal voids, increasing structural stability and load-bearing capacity.

Heat Treatment: By refining the alloy's grain structure and relieving internal stresses, heat treatment enhances both the strength and fatigue resistance of the alloy.

Thermal Barrier Coatings (TBC): Applied to protect against oxidation and heat degradation, TBCs are essential for components exposed to high temperatures.

Post-processing transforms raw superalloy components into high-performance parts that meet the demands of extreme applications, ensuring Neway's superalloy components deliver consistent quality and reliability.

Hot Isostatic Pressing (HIP) for Superalloy Strength Enhancement

How HIP Works

Hot Isostatic Pressing (HIP) involves placing superalloy components in a high-temperature chamber subjected to isostatic (uniform) pressure from an inert gas, usually argon. This process typically operates at temperatures between 1000°C and 2000°C and pressures of up to 30,000 psi. The heat and pressure eliminate porosity and densify the material, reducing internal voids and defects that weaken the part.

Strength and Durability Benefits

HIP enhances the strength and durability of superalloy components by filling microvoids and closing microcracks within the alloy. The densified structure resulting from HIP treatment has superior mechanical properties, including increased load-bearing capacity, fatigue resistance, and resistance to creep (gradual deformation over time). For high-temperature applications, the improved microstructure prevents grain boundary sliding, making the part more stable under stress.

Applications in High-Stress Environments

HIP-treated superalloy parts are widely used in applications that require maximum structural integrity and durability. These parts can be found in jet engines, gas turbines, and power plants, which must withstand extreme thermal and mechanical loads without failure. In the aerospace industry, HIP-treated turbine blades and vanes offer enhanced longevity, resulting in reduced downtime and lower maintenance costs.

Heat Treatment for Optimized Superalloy Performance

Types of Heat Treatment

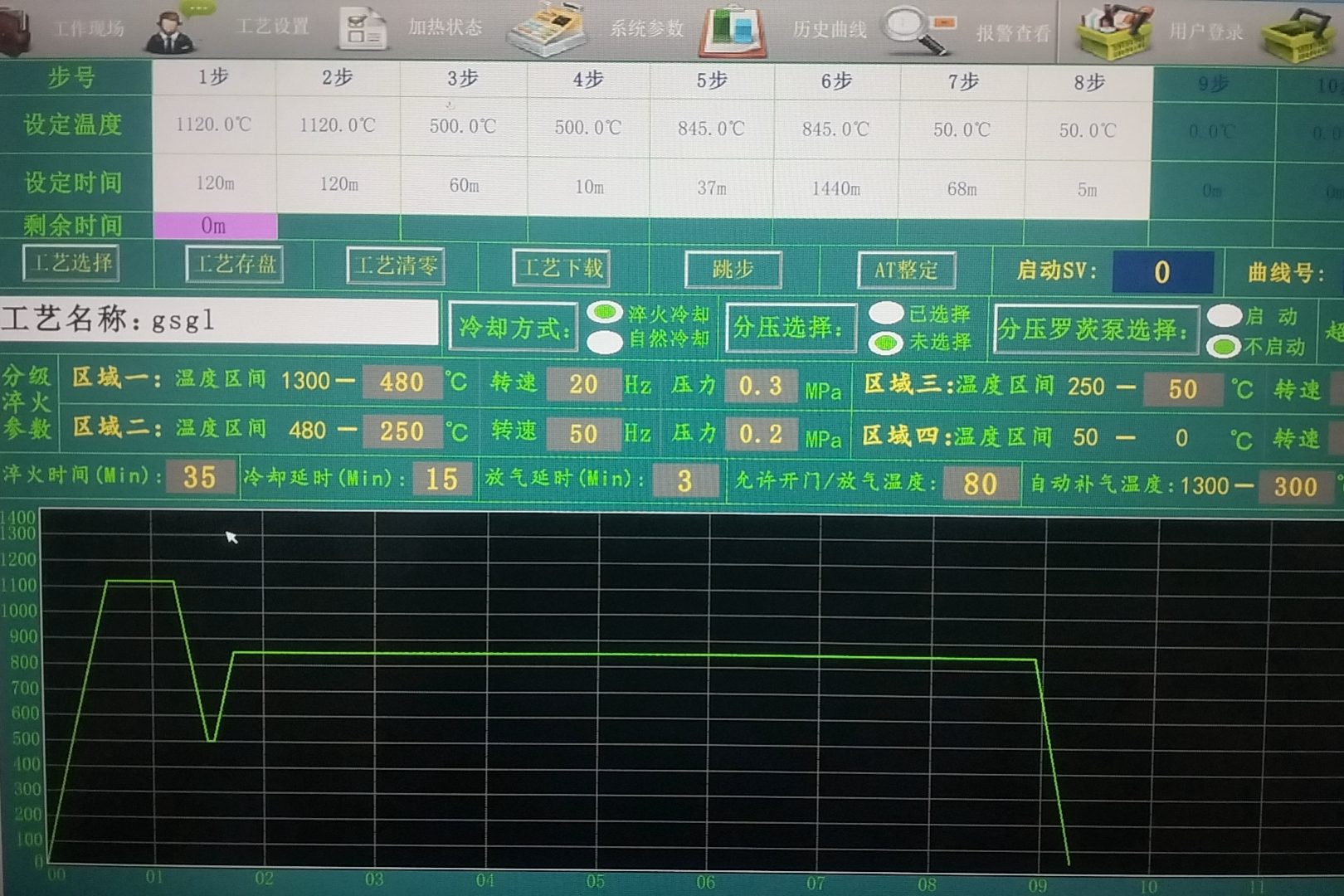

Heat treatment is a controlled process that involves heating and cooling to enhance the material's properties. Some common heat treatments for superalloys include:

Annealing: This treatment relieves internal stresses, making the material more malleable and less prone to cracking.

Solution Treatment: Solution treatment optimizes corrosion resistance and toughness by dissolving alloying elements into a single-phase matrix.

Aging: Aging promotes the formation of fine precipitates, which strengthen the alloy and enhance creep resistance, a crucial property for high-temperature applications.

Microstructure Stabilization

Heat treatment stabilizes the microstructure of superalloys, a necessary enhancement for high-temperature applications. By refining the grain structure and promoting the even distribution of alloying elements, heat treatment improves toughness, high-temperature stability, and fatigue resistance. This stabilization is significant for preventing creep, where a superalloy part slowly deforms over time due to prolonged exposure to high temperatures.

Applications and Benefits

Heat-treated superalloy components, such as turbine blades, rely on enhanced properties for reliable thermal and mechanical stress performance. In power generation and aerospace, heat treatment ensures that parts, such as nozzles and combustion chambers, resist deformation, thereby reducing wear and extending their service life. With a more stable microstructure, these parts provide consistent performance even under demanding conditions.

Surface Treatments for Enhanced Superalloy Part Longevity

Thermal Barrier Coating (TBC)

Thermal Barrier Coating (TBC) is an insulative ceramic layer that protects superalloy parts from extreme temperatures. TBC reduces heat transfer from the environment to the alloy, enabling parts to operate at higher temperatures without degrading. This coating benefits components such as turbine blades and combustion chambers, which are continuously exposed to high-temperature gases.

Corrosion and Oxidation Resistance Coatings

Superalloy parts often operate in corrosive or oxidative environments, particularly in chemical processing and marine applications. Protective coatings prevent surface degradation by shielding the part from oxygen, water, and other corrosive agents. This barrier enhances the alloy's strength and lands the component's operational life by preventing oxidation and corrosion.

Applications of Surface Treatments

Surface treatments are widely used in industries that require high environmental resistance, such as the marine, chemical processing, and power generation sectors. Components treated with TBC, for example, last longer and perform more reliably in gas turbines, where extreme temperatures and oxidative conditions would otherwise wear down untreated parts.

Mechanical Strengthening Techniques: Shot Peening and Laser Peening

Shot Peening

Shot peening involves bombarding the surface of a superalloy part with small spherical particles at high velocities. The impact introduces compressive stresses on the surface layer, which counteract tensile stresses that can lead to cracking. This process enhances fatigue resistance and helps prevent premature failure, which is particularly beneficial for components subjected to cyclic loading.

Laser Peening

Laser peening uses high-energy laser pulses to create deeper compressive layers than shot peening, making it ideal for parts that experience high-stress levels. This treatment is particularly beneficial for components like turbine blades that require enhanced resistance to repetitive stress. Laser peening improves surface strength, reduces the likelihood of fatigue failures, and extends the part's operational life.

Applications

Shot and laser peening are applied to components that experience cyclic stresses, such as turbine blades and engine casings. By strengthening the surface layer, these treatments enable components to withstand repetitive stress without cracking, thereby preserving their structural integrity over time.

Precision Machining for Dimensional Stability and Strength

Superalloy CNC Machining

Precision CNC machining ensures that superalloy parts meet exacting tolerances and dimensional accuracy. This process refines the part's geometry, eliminating surface irregularities and achieving smooth finishes that reduce stress concentrators. This enhancement is crucial for components that require precise dimensions to fit or interact seamlessly with other parts.

Eliminating Surface Defects

CNC machining removes surface defects, such as burrs or sharp edges, which can create points of weakness under stress. By refining the part's surface, CNC machining minimizes stress concentrations that could lead to fatigue or fracture. The process yields more vital and reliable parts, suited for critical applications.

Applications

Precision-machined superalloy parts are commonly used in compressor blades, turbine discs, and structural casings, where accuracy is critical for functionality and durability. CNC machining ensures that each component is optimized for strength and performance in high-stress environments, helping to prevent issues such as misalignment or excessive wear.

Comprehensive Testing and Analysis for Quality Assurance

Importance of Testing

Testing is essential to verify the effectiveness of post-processing techniques and ensure each part meets the required mechanical and environmental standards. Quality assurance tests confirm that enhanced strength, corrosion, and fatigue resistance have been achieved.

Common Testing Techniques

Tensile Testing: Determines the material's strength and flexibility, ensuring it meets load-bearing requirements.

Fatigue Testing: Evaluates resistance to cyclic loading, which is crucial for parts subjected to repetitive stress.

Corrosion and Oxidation Testing: Verifies the effectiveness of surface coatings in preventing environmental degradation.

Neway's Quality Assurance Standards

Neway adheres to stringent quality assurance standards, conducting thorough testing at every stage of production. Our commitment to excellence ensures that each superalloy part meets the rigorous demands of industries where precision and reliability are paramount.

Industry Applications of Post-Processed Superalloy Parts

Aerospace

Post-processed superalloy parts are critical for improving engine efficiency, fatigue resistance, and overall performance in aerospace. HIP, heat treatment, and surface coatings allow components like turbine blades and nozzles to endure high temperatures and cyclic stresses without compromising structural integrity. The result is enhanced safety and reliability for aerospace applications.

Power Generation

Power generation turbines operate under continuous high temperatures and pressures. Post-processing ensures that components like turbine discs and combustion chambers possess the strength and stability to perform reliably, even under prolonged stress. This durability reduces maintenance needs, improving plant efficiency and lowering operational costs.

Oil and Gas

The oil and gas sector exposes components to extreme pressures and corrosive substances. Post-processing treatments enhance the performance of superalloy parts, including valves, pump components, and high-pressure casings, enabling them to operate reliably under harsh conditions. This increased resilience enhances equipment reliability and safety.