High-Performance Plastics

Material Introduction

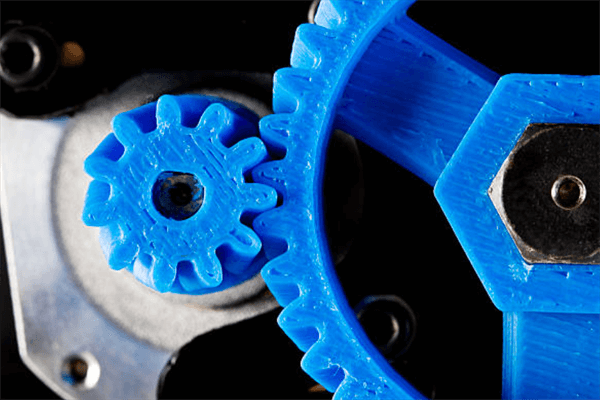

High-performance plastics represent a class of engineered polymers designed for extreme mechanical, thermal, and chemical requirements, making them ideal for advanced additive manufacturing applications. These materials deliver superior strength-to-weight ratios, excellent dimensional stability, and exceptional resistance to heat, wear, and aggressive chemicals. Through Neway AeroTech’s dedicated high-performance plastics 3D printing, engineers can produce functional prototypes and complex end-use components that surpass the capabilities of conventional thermoplastics, such as ABS or PLA. These advanced polymers enable the creation of lightweight structures, high-temperature housings, aerospace brackets, medical device components, and chemical-resistant parts with outstanding durability. Their compatibility with industrial-grade 3D printing systems enables precise geometries, consistent mechanical properties, and design freedom, elevating product performance across demanding industries such as aerospace, energy, medical, and automotive.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | High-Performance Plastics | PEEK, PEI, PPSU |

Europe | Advanced Engineering Thermoplastics | PEEK, ULTEM™ |

Japan | 高機能プラスチック | PEEK, PEKK |

China | 高性能工程塑料 | PEEK, PPSU |

Industry Classification | High-Temperature Polymers | PEEK, PEI, PTFE |

Alternative Material Options

Depending on engineering requirements, several material families can be used as alternatives to high-performance plastics. For applications requiring exceptional mechanical strength and rigidity, engineering-grade polycarbonate (PC) provides excellent impact and heat resistance. When flexibility is essential, especially for wearable and dynamic applications, TPU offers superior elasticity. If fine detail and surface finish are the primary goals, photopolymer-based solutions like standard resin deliver high-resolution results. For balanced strength, chemical resilience, and low friction, robust materials such as nylon are widely used in production-grade components. When clarity and toughness are required, PETG serves as a reliable, visually appealing option. Each alternative provides specific advantages depending on load, temperature, flexibility, and environmental exposure.

Design Purpose

High-performance plastics were engineered to replace metal components in environments where weight reduction, chemical resistance, and thermal stability are critical. Their design intent focuses on achieving high mechanical reliability while resisting deformation under heat, oxidation, or prolonged stress. In additive manufacturing, these materials are used to produce complex structures that demand metal-like performance without the associated weight or machining cost. Industries rely on them for precision housings, functional brackets, medical components, high-temperature insulators, and chemical-resistant systems. Their ability to maintain performance under extreme conditions allows engineers to expand design possibilities in aerospace, automotive, energy, and medical applications.

Chemical Composition (Generic High-Performance Polymer Families)

Material Type | Key Chemical Structure |

|---|---|

PEEK | Polyether Ether Ketone (Aromatic ketone backbone) |

PEI | Polyetherimide (Aromatic imide/ether structure) |

PPSU | Polyphenylsulfone (Aromatic sulfone chain) |

PTFE | Fluorinated polymer (Carbon-fluorine chain) |

Physical Properties (General Range)

Property | Value |

|---|---|

Density | 1.20–1.40 g/cm³ |

Melting Point | 220–343°C (depending on polymer) |

Heat Deflection Temperature | 170–260°C |

Water Absorption | Very low |

Thermal Stability | Excellent |

Mechanical Properties (General Range)

Property | Typical Value |

|---|---|

Tensile Strength | 70–100 MPa |

Flexural Strength | 90–140 MPa |

Elongation at Break | 10–50% |

Impact Resistance | High |

Fatigue Resistance | Excellent |

Key Material Characteristics

Exceptional high-temperature resistance suitable for demanding aerospace and industrial environments

Superior mechanical strength and stiffness comparable to lightweight metals

Excellent chemical resistance to solvents, fuels, acids, and industrial chemicals

Outstanding dimensional stability under thermal cycling and mechanical loads

Low moisture absorption ensures reliable performance in humid or aquatic environments

Excellent wear resistance suitable for sliding, rotating, or friction-intensive applications

High dielectric strength ideal for electrical insulation components

Biocompatibility options available for medical and food-grade applications

Compatibility with precision additive manufacturing processes enabling complex geometries

Lower weight than metal alternatives while maintaining structural reliability

Strong fatigue resistance for long-life mechanical assemblies

Smooth surface finish suitable for consumer and engineering applications

Manufacturability in Different Processes

FDM/FFF printing: High-performance plastics require elevated nozzle and chamber temperatures, making them suitable for functional prototypes and engineering-grade components.

SLS: Powder-based high-temperature polymers enable isotropic strength and excellent mechanical uniformity.

SLA substitutes: High-strength, tough resin can complement precision applications that require rigid performance.

CNC machining: These plastics exhibit clean cutting behavior with proper tooling and coolant strategies.

Injection molding: While suitable, tooling costs are higher; additive manufacturing offers a cost-effective alternative for low-volume production.

Hybrid manufacturing: Components can be integrated with metal frames to achieve lightweight structural solutions.

Prototype validation: High-performance plastics seamlessly integrate into Neway’s 3D printing service workflows for rapid testing and product iteration.

Suitable Post-Processing Methods

Thermal annealing to relieve internal stresses and improve crystallinity

Dimensional finishing through light machining, sanding, or polishing

Chemical smoothing for select polymer families

Dyeing or pigmentation for custom appearance

Sterilization for medical and laboratory applications

Structural testing under standardized material testing procedures

Assembly preparation using threaded inserts or adhesive bonding

Surface sealing for improved chemical and moisture resistance

Common Industries and Applications

Aerospace: high-strength brackets, ducting components, lightweight housings

Automotive: thermal insulators, underhood components, structural connectors

Energy: chemical-resistant fittings, electrical insulation parts, thermal shields

Medical: surgical tool housings, sterilizable components, diagnostic device parts

Industrial machinery: gears, wear-resistant guides, structural fixtures

Electronics: heat-resistant casings, connectors, precision insulating components

When to Choose This Material

When metal-like performance is required without the added weight

When parts must withstand high temperatures, chemicals, or mechanical stress

When dimensional stability under extreme conditions is essential

When complex geometries exceed the limitations of injection molding

When low moisture absorption and long-term stability are critical

When the product demands clean, precise tolerances and superior durability

When lightweight structural components must perform under continuous load

When the application requires biocompatibility or sterilization capability