Titanium Alloy Vacuum Investment Casting Parts Welding Workshop

Advanced Welding for Precision-Cast Titanium Components

Titanium alloy parts produced by vacuum investment casting offer high strength-to-weight ratios, corrosion resistance, and heat stability, making them ideal for aerospace, medical, and chemical industries. However, welding titanium castings requires an inert atmosphere, clean surface preparation, and precise thermal control to avoid contamination, embrittlement, or distortion.

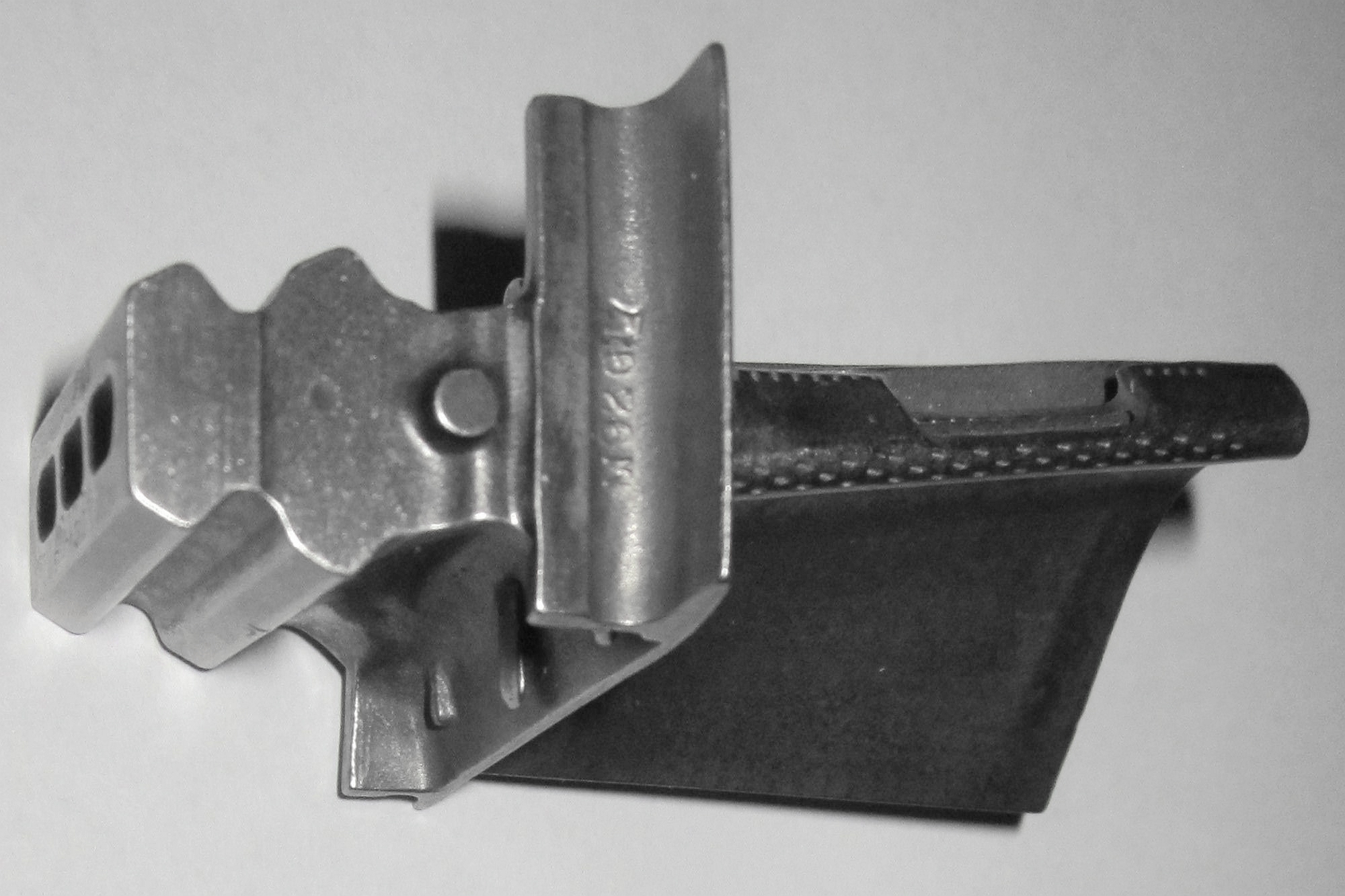

Neway AeroTech operates a dedicated superalloy welding workshop optimized for titanium alloy castings. Our facility is equipped for TIG, laser, and plasma arc welding of precision-cast components such as brackets, turbine casings, pressure housings, and orthopedic structures using alloys like Ti-6Al-4V and Ti-6Al-4V ELI.

Core Welding Capabilities for Titanium Alloy Castings

Titanium welding requires ultra-clean environments, consistent heat input, and precise joint fit-up. Neway AeroTech ensures integrity through:

Inert argon atmosphere welding chambers for oxidation-free TIG and laser welds

TIG welding using filler rods matched to titanium grade

Laser welding for thin wall joining with minimal heat-affected zone

Post-weld stress relief and polishing

Our process adheres to AWS D17.1, AMS 2817, and ASTM F136 quality standards.

Titanium Alloys Commonly Welded

Alloy | Max Temp (°C) | Yield Strength (MPa) | Applications |

|---|---|---|---|

400 | 880 | Aerospace brackets, turbine casings | |

400 | 860 | Orthopedic implants, precision assemblies | |

350 | 620 | Tubular assemblies, medical tubes | |

540 | 930 | High-pressure housings, jet engine frames |

These grades are selected for weldability, corrosion resistance, and biocompatibility.

Case Study: Ti-6Al-4V ELI Orthopedic Component Laser Welding

Project Background

A biomedical client needed precise seam welding for Ti-6Al-4V ELI spinal implant components. Welds were performed in an inert chamber using pulsed laser for fine control. After stress relief heat treatment, SEM and X-ray inspection confirmed microstructure uniformity and porosity-free joints.

Typical Titanium Welded Part Applications and Industries

Component | Weld Type | Alloy | Industry |

|---|---|---|---|

Aerospace Bracket | TIG weld, 2-pass | Ti-6Al-4V | |

Spinal Implant | Laser seam weld | Ti-6Al-4V ELI | |

Turbine Shell | TIG root and fill | Ti-6Al-2Sn-4Zr-6Mo | |

Pressure Housing | Plasma keyhole weld | Ti-3Al-2.5Sn |

All welded assemblies are validated for fatigue, stress, and surface integrity.

Welding Challenges in Titanium Alloy Castings

Atmospheric contamination leads to alpha case formation and embrittlement

Crack initiation due to thermal gradients in thick sections

Weld bead oxidation from low-purity shielding gases

Poor fusion at root without tight joint fit-up

Porosity risks from hydrogen contamination and improper filler

Certified Welding and Post-Weld Processing Solutions

Welding in glove boxes or sealed chambers for maximum inert gas coverage

Argon backpurging systems for full weld coverage

**Post-weld stress relief at 600–650°C for Ti-6Al-4V

Surface passivation and ultrasonic cleaning to remove oxidation

**Optional HIP for structural-grade components

Results and Verification

Welding Execution

Joints were welded under oxygen-free conditions using argon-purged TIG and pulsed laser beams. Pre-weld machining was verified by CMM. Post-weld grinding and polishing maintained tolerances within ±0.01 mm.

Post-Weld Treatment

Parts underwent heat treatment to reduce residual stress and improve grain structure. Optional HIP removed subsurface porosity. Surfaces were passivated and inspected for oxide removal.

Inspection

X-ray and SEM confirmed full fusion and clean grain boundaries. CMM validated dimensional targets post-welding. All parts passed ASTM F67 and AMS 4943 weld quality standards.

FAQs

What shielding methods are used for titanium welding?

Can cast titanium components be laser welded?

What heat treatment is applied post-welding?

How is weld contamination prevented in titanium parts?

What industries benefit most from titanium welding services?