Rene 65 Superalloy Casting Gas Turbine Vane Components Foundry

Introduction

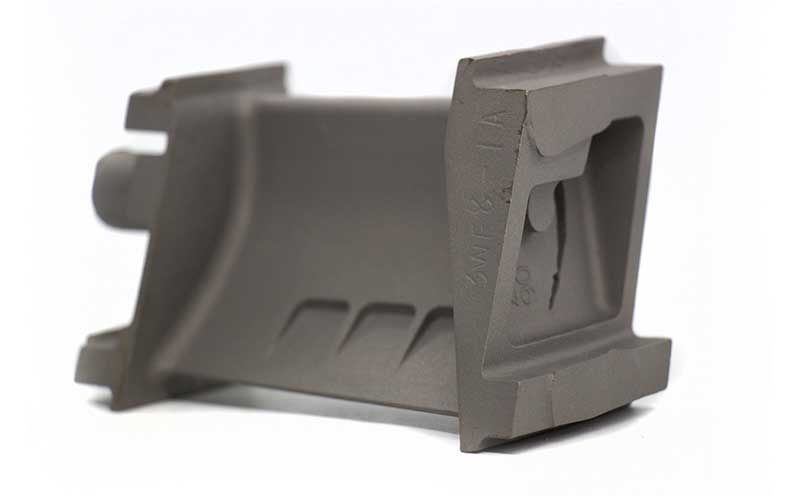

Rene 65 is a high-strength, nickel-based superalloy engineered for advanced gas turbine applications requiring excellent creep resistance, fatigue strength, and thermal stability up to 980°C. As a specialized superalloy casting foundry, we produce precision Rene 65 turbine vane components using vacuum investment casting, achieving tight dimensional tolerances (±0.05 mm), equiaxed grain structures, and porosity under 1%.

Our castings are optimized for aerospace and industrial gas turbines, delivering exceptional durability and mechanical integrity in harsh hot-section environments.

Core Technology: Vacuum Investment Casting of Rene 65

We apply vacuum investment casting to manufacture Rene 65 components. The alloy is vacuum melted and poured at ~1450°C into ceramic shell molds (8–10 layers) preheated to ~1100°C. Controlled cooling rates (30–80°C/min) produce uniform equiaxed grain structures (0.5–2 mm) and eliminate solidification defects. The process delivers dimensional accuracy within ±0.05 mm and consistently low porosity (<1%).

Material Characteristics of Rene 65 Alloy

Rene 65 is a γ′-strengthened nickel superalloy developed for turbine vanes, blades, and structural hot-section components. Its balanced combination of strength, ductility, and thermal fatigue resistance makes it ideal for high-load turbine environments. Key properties include:

Property | Value |

|---|---|

Density | 8.36 g/cm³ |

Ultimate Tensile Strength (at 815°C) | ≥1240 MPa |

Yield Strength (at 815°C) | ≥1050 MPa |

Elongation | ≥12% |

Creep Rupture Strength (1000h @ 927°C) | ≥200 MPa |

Operating Temperature Limit | Up to 980°C |

Oxidation Resistance | Excellent |

Rene 65 maintains phase stability and mechanical integrity under sustained stress, thermal cycling, and hot gas flow exposure.

Case Study: Gas Turbine Vane Component Production

Project Background

A gas turbine OEM required durable high-pressure vane segments for the first-stage nozzle of an industrial turbine operating at 950°C. Rene 65 was selected for its superior creep and fatigue resistance. We delivered vacuum-cast components meeting AMS and OEM specifications with post-HIP and CNC finishing for tight dimensional control and thermal fatigue performance.

Typical Gas Turbine Vane Applications

HPT Nozzle Guide Vanes (e.g., Siemens SGT-800, GE LM6000): Load-bearing Rene 65 vanes exposed to high-velocity combustion gas and continuous thermal cycling.

Transition Zone Vane Segments: Intermediate-stage vanes bridging combustor and turbine that require dimensional stability and oxidation protection.

Stationary Airfoil Platforms: High-temperature platforms in power turbines designed for long life under creep and stress rupture conditions.

Core Engine Cooling Vanes: Precision-cast vanes with internal channels for thermal management under high-pressure, high-temperature gas flow.

These vane components operate in extreme thermal environments and require both dimensional precision and long-term mechanical durability.

Manufacturing Solutions for Rene 65 Vane Components

Casting Process Wax patterns are injected, assembled, and invested in multi-layer ceramic shell molds. Vacuum melting and casting at ~1450°C ensure metallurgical purity. Solidification is tightly controlled to achieve uniform grain size and avoid hot tearing.

Post-processing Hot Isostatic Pressing (HIP) at 1190°C and 100 MPa eliminates internal porosity. Solution and aging treatments are performed to refine γ′ precipitation and enhance high-temperature strength.

Post Machining CNC machining is applied for sealing faces, root fits, and aerodynamic contours. EDM allows finishing of cooling hole exits and trailing edges. Deep hole drilling is used for internal air cooling passages.

Surface Treatment Thermal barrier coatings (TBC) are applied via APS or EB-PVD for improved oxidation resistance and temperature reduction. Aluminide coatings can also be used for protective surface diffusion.

Testing and Inspection Every vane undergoes X-ray radiographic inspection, CMM dimensional analysis, and elevated-temperature mechanical testing. Metallographic evaluation confirms phase stability and grain uniformity.

Core Manufacturing Challenges

Casting complex airfoil geometry with equiaxed grain uniformity and minimal distortion.

Maintaining surface integrity and oxidation resistance after thousands of operating hours above 950°C.

Achieving tight tolerances for root fit, trailing edge, and cooling slot alignment.

Results and Verification

Dimensional precision within ±0.05 mm confirmed by 3D CMM scanning.

Porosity <1% verified via radiography after HIP consolidation.

Creep rupture strength ≥200 MPa at 927°C confirmed in 1000-hour test cycles.

Thermal fatigue resistance validated through 1000-cycle thermal gradient testing at 980°C.

FAQs

Why is Rene 65 ideal for casting gas turbine vane components?

What heat treatment is used to optimize Rene 65 properties?

Can Rene 65 vanes be customized with internal cooling and TBC coatings?

How does your foundry ensure grain structure and casting soundness?

What testing standards are applied to confirm high-temperature performance compliance?