CMSX-6 Single Crystal Casting Gas Turbine Blades

Introduction

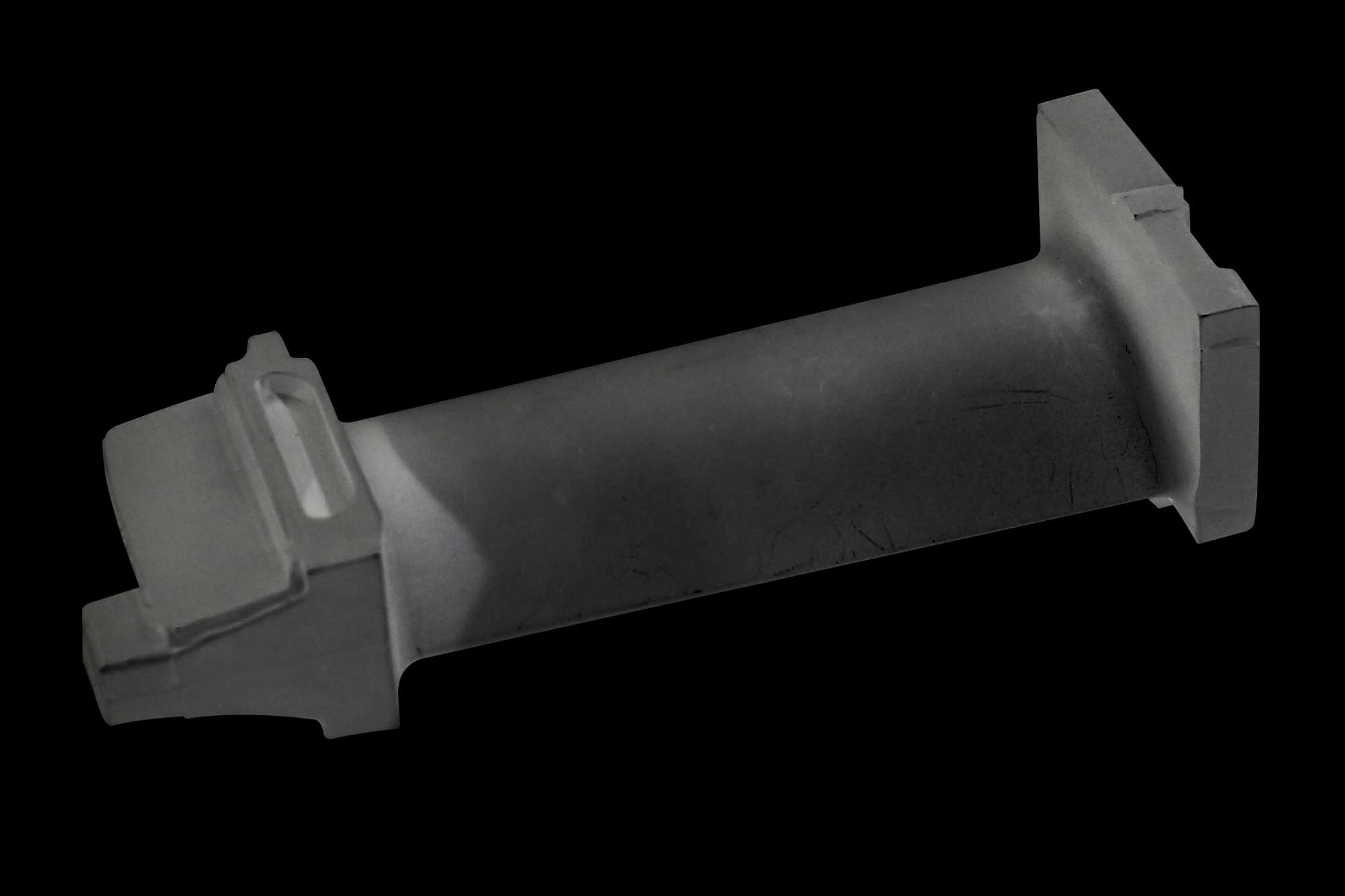

CMSX-6 single crystal casting is a reliable solution for manufacturing gas turbine blades used in high-pressure and intermediate-pressure turbine stages. At Neway AeroTech, we utilize advanced vacuum investment casting and directional solidification technology to produce CMSX-6 turbine blades for aerospace engines, power generation, and military turbine systems.

CMSX-6 offers excellent creep resistance, good thermal fatigue strength, and oxidation resistance at temperatures up to 1100°C, making it a robust material choice for performance-critical turbine airfoils.

Core Technology of CMSX-6 Blade Casting

High-Precision Wax Patterning: Wax blades are molded with ±0.05 mm dimensional tolerance to replicate complex airfoil, shroud, and root geometries.

Ceramic Shell Mold Construction: 8–10 ceramic layers are applied to form vacuum-ready molds that resist thermal and mechanical stress during casting.

Vacuum Melting and Pouring: CMSX-6 alloy is melted and cast under vacuum (<10⁻³ torr) to preserve chemical composition and prevent oxidation.

Directional Solidification (Bridgman Process): Controlled withdrawal at 3–5 mm/min ensures <001> crystal growth and eliminates grain boundaries.

Heat Treatment: Solution and aging treatment stabilizes γ′ distribution and dissolves residual segregation for optimal strength.

CNC Machining: Fir-tree roots, seal slots, and platform faces are machined to ±0.02 mm using multi-axis CNC machining.

Thermal Barrier Coating (Optional): TBC coatings improve oxidation resistance and extend service life in hot-section environments.

Material Properties of CMSX-6

Property | Value |

|---|---|

Max Operating Temperature | 1100°C |

Ultimate Tensile Strength | ≥1220 MPa |

Creep Rupture Life | >1000 hrs at 1050°C / 137 MPa |

γ′ Volume Fraction | ~60–65% |

Oxidation Resistance | Good |

Grain Structure | Single crystal <001> |

Fatigue Resistance | Moderate to High |

Case Study: CMSX-6 Turbine Blades for Military and Power Gas Turbines

Project Background

A defense turbine program required single crystal blades for an intermediate-pressure turbine (IPT) stage with long-term operation at 1050°C and high-cycle fatigue exposure. CMSX-6 was selected due to its balance of performance, castability, and cost-effectiveness.

Applications of CMSX-6 Turbine Blades

GE T700 Turbine Blades: CMSX-6 blades used in mid-pressure stages for helicopter engines, offering thermal stability under repeated load cycles.

Rolls-Royce Spey Derivative Engines: Applied in marine propulsion systems where corrosion and fatigue resistance are essential.

Industrial Gas Turbine Modules: CMSX-6 used in backup and peaking turbines where creep strength and manufacturability are both required.

Military Turbojet Engines: CMSX-6 blades integrated into secondary stages for extended durability in harsh environments.

Manufacturing Process Overview

Wax Cluster Assembly: Blades arranged to ensure uniform <001> growth and minimize stray grain formation.

Shell Mold Building: Ceramic layers are applied in a controlled environment to prevent cracking and ensure shell uniformity.

Vacuum Casting and DS Withdrawal: Casting performed with thermal gradient >10°C/mm and withdrawal rate of 4 mm/min to control microstructure.

Heat Treatment: Solutioning at 1260–1280°C followed by aging at 1080°C and 870°C enhances γ′ precipitation.

Machining and Finishing: Precision CNC machining of mating interfaces, platform faces, and flow path surfaces to Ra ≤1.6 µm.

Surface Coating (Optional): Plasma-sprayed TBC applied for blades exposed to prolonged high-temperature combustion gases.

Quality Inspection: Blades inspected with X-ray, EBSD for crystal orientation, and CMM for geometric compliance.

Results and Validation

Creep Performance: CMSX-6 blades passed 1000-hour creep testing at 1050°C/137 MPa with deformation under 1%.

Crystal Orientation Accuracy: EBSD confirmed <001> alignment within 10° deviation across all blades with zero stray grains detected.

Fatigue Resistance: Survived >20,000 thermal cycles from ambient to 1050°C without surface cracking or microstructural degradation.

Dimensional Precision: CNC-machined features confirmed within ±0.02 mm using automated CMM inspection.

Surface Protection: TBC-coated blades maintained coating integrity after 1200-hour hot gas path exposure.

FAQs

What differentiates CMSX-6 from newer CMSX alloys like CMSX-4 or CMSX-10?

Can CMSX-6 blades be coated for improved oxidation resistance?

What turbine stages are most suitable for CMSX-6 blade use?

How is single crystal integrity ensured during CMSX-6 casting?

Does Neway AeroTech support small-lot or prototype CMSX-6 blade production?