316L Bespoke Nuclear Parts Additive Manufacturing Service

Introduction to 316L Stainless Steel Additive Manufacturing for Nuclear Applications

316L stainless steel is a low-carbon austenitic alloy known for its exceptional corrosion resistance, high ductility, and radiation tolerance. These characteristics make it ideal for custom components in nuclear environments—particularly where performance in high-radiation, high-humidity, and thermal cycling conditions is essential.

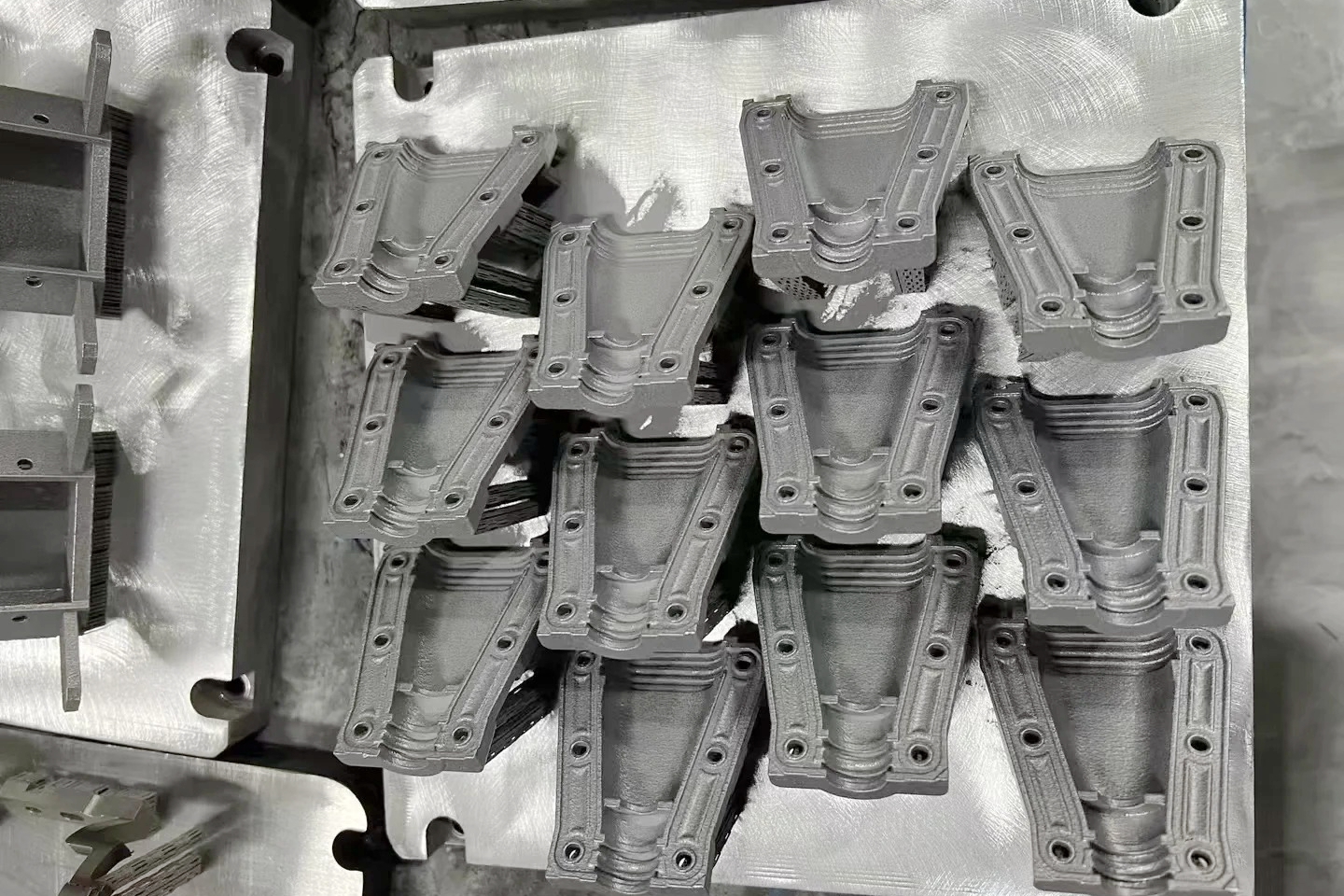

At Neway Aerotech, we provide 316L stainless steel 3D printing services using Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) to deliver bespoke nuclear-grade parts such as shielding brackets, valve components, sensor housings, and reactor internals.

Additive Manufacturing Process for Nuclear Components

Technology Parameters

Technology | Layer Thickness (μm) | Tolerance (mm) | Surface Finish (Ra, μm) | Key Applications |

|---|---|---|---|---|

SLM | 30–50 | ±0.05 | 6–10 | Internals, control brackets, threaded housings |

DMLS | 40–60 | ±0.08 | 8–15 | Sensor mounts, valve adapters, instrumentation plates |

SLM is preferred for geometrically complex, mission-critical parts requiring high density and fine feature accuracy.

Why 316L Stainless Steel is Ideal for Nuclear Environments

Property | Value | Nuclear Application Benefit |

|---|---|---|

Corrosion Resistance | Excellent in chloride, steam, and radiation conditions | Prolongs component life in reactor and auxiliary systems |

Radiation Resistance | Superior | Maintains ductility and strength post-irradiation |

Thermal Stability | Up to 870°C | Operates under heat flux in primary and secondary loops |

Low Carbon Content | ≤ 0.03% | Prevents sensitization and intergranular corrosion |

Weldability | Excellent | Enables hybrid assembly and maintenance integration |

Post-Processing Strategy

Stress Relief: 870°C for 2 hours under inert gas to reduce residual stress.

HIP: Optional for fatigue-sensitive or pressurized assemblies to eliminate porosity.

CNC Machining: Applied to sealing faces, threads, and flange holes for precision.

Passivation: Enhances surface stability and resistance to decontamination fluids.

Case Study: 316L Printed Radiation Sensor Housing for Containment Vessel

Project Background

A nuclear operator required a corrosion-resistant housing for a gamma sensor installed inside a steam containment boundary. The part needed to integrate flow baffling, cable routing features, and threaded M12 connections within a limited volume envelope.

Manufacturing Workflow

Design: STL geometry with 2 mm walls, integral baffling, and M12x1.5 threaded ports.

Material: Certified 316L stainless steel powder, D50 = 35 μm, low carbon content.

Printing: SLM at 40 μm layer height, 300 W laser, argon environment.

Post-Processing:

Stress-relieved and bead blasted.

Thread features CNC machined to ±0.01 mm.

All surfaces passivated to ASTM A967 standards.

Inspection: CMM confirmed geometric conformance; pressure testing at 5 bar for sealing integrity.

Results and Verification

The finished 316L housing was installed in a live reactor site after passing radiation qualification and pressure retention testing. Mechanical testing showed 630 MPa tensile strength and no embrittlement after gamma exposure equivalent to 10⁵ Gy. The integrated design also eliminated three brazed joints, reducing contamination risks.

FAQs

How does 316L stainless steel perform under neutron and gamma radiation exposure?

What is the maximum pressure rating of printed 316L containment parts?

Can 316L parts be printed with embedded cooling channels or baffling features?

Are HIP and passivation required for every nuclear-grade component?

What certifications are available for 316L 3D printed nuclear components?