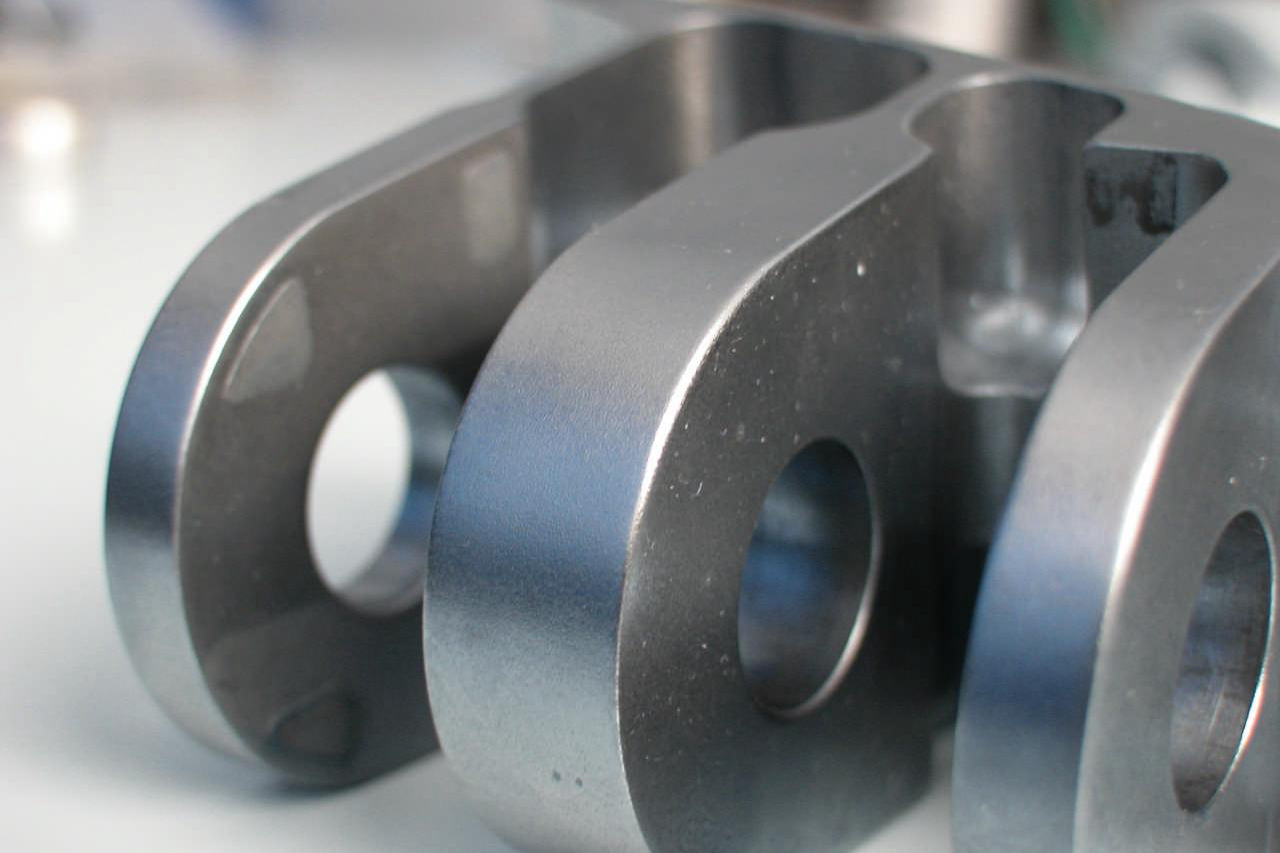

Oil and Gas Inconel Parts Custom Superalloy Components Manufacturer

Introduction to Inconel Superalloy Components in Oil and Gas Applications

Inconel superalloys provide outstanding corrosion resistance, mechanical strength, and exceptional thermal stability, making them indispensable for critical oil and gas industry components operating under extreme conditions. Neway AeroTech specializes in manufacturing custom Inconel parts, leveraging advanced technologies such as vacuum investment casting and directional solidification casting.

With deep industry expertise, we ensure superior component reliability, extended service life, and optimal performance for harsh operational environments encountered in upstream and downstream oil and gas applications.

Core Challenges in Manufacturing Inconel Components

Producing custom Inconel components involves critical manufacturing challenges:

Corrosion and Sulfide Stress Cracking Resistance: Maintaining durability under harsh, acidic conditions containing hydrogen sulfide (H₂S).

Precision Machining: Handling low thermal conductivity and rapid work-hardening nature of Inconel, complicating machining processes.

High-Temperature Strength: Ensuring structural stability at operating temperatures exceeding 800°C.

Dimensional Precision: Achieving complex component geometries within tight dimensional tolerances of ±0.10 mm.

Detailed Manufacturing Processes for Inconel Components

Vacuum Investment Casting

Precision wax models accurately replicate intricate geometries.

Multiple ceramic layers form robust molds; wax is removed via autoclaving at ~180°C.

Inconel alloys cast under vacuum conditions (<0.01 Pa), ensuring high purity and reduced defects.

Slow controlled cooling (~30°C/hour) minimizes residual stresses and enhances component stability.

Directional Solidification Casting

Solidification under precise thermal gradients (20–50°C/cm) to achieve directionally aligned grain structures.

Provides enhanced creep strength and superior fatigue resistance.

Carefully managed solidification rates (20–35°C/hour) significantly reduce porosity.

Comparative Analysis of Inconel Manufacturing Processes

Process | Dimensional Accuracy | Surface Finish | Production Efficiency | Complexity Capability |

|---|---|---|---|---|

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | Moderate | High |

Directional Solidification | ±0.20 mm | Ra 6.3–12.5 µm | Moderate | Moderate |

CNC Machining | ±0.01 mm | Ra 0.8–3.2 µm | Moderate | Moderate |

SLM 3D Printing | ±0.05 mm | Ra 6.3–12.5 µm | High | Very High |

Manufacturing Process Selection Strategy for Inconel Components

Vacuum Investment Casting: Ideal for components with complex internal geometries needing precise dimensional tolerances (~±0.15 mm) for medium-volume production.

Directional Solidification Casting: Preferred for components requiring superior creep and fatigue resistance, aligned grain structures, and ±0.20 mm accuracy.

CNC Machining: Optimal for high precision finishing, achieving extremely tight tolerances (±0.01 mm) and excellent surface finishes.

SLM 3D Printing: Recommended for rapid prototyping and intricate cooling channels with ±0.05 mm dimensional accuracy.

Material Performance Matrix for Inconel Alloys in Oil and Gas

Material | Tensile Strength (MPa) | Yield Strength (MPa) | Max Operating Temp (°C) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

930 | 517 | 980 | Outstanding | Valves, seals, tubing | |

1375 | 1100 | 700 | Excellent | Drilling tools, pumps | |

770 | 440 | 550 | Exceptional | Chemical processing equipment | |

1185 | 868 | 700 | Excellent | Downhole tools, springs | |

655 | 310 | 1095 | Exceptional | Heat exchanger tubing | |

965 | 690 | 650 | Superior | Wellhead equipment, fasteners |

Material Selection Strategy for Inconel Components

Inconel 625: Chosen for valves and tubing due to exceptional corrosion resistance and tensile strength (930 MPa) at temperatures up to 980°C.

Inconel 718: Recommended for drilling tools and pumps requiring high yield strength (1100 MPa) at temperatures of 700°C.

Inconel 825: Ideal for chemical processing equipment, offering superior corrosion protection and stability up to 550°C.

Inconel X-750: Optimal for downhole tools and springs, providing high strength (1185 MPa) and fatigue resistance at 700°C.

Inconel 600: Preferred for heat exchanger tubing, delivering excellent oxidation resistance at temperatures up to 1095°C.

Inconel 925: Selected for wellhead equipment due to high yield strength (690 MPa), corrosion resistance, and suitability up to 650°C.

Key Post-processing Technologies for Inconel Components

Hot Isostatic Pressing (HIP): Eliminates micro-porosity and enhances mechanical properties at pressures (~150 MPa) and temperatures (~1200°C).

Heat Treatment: Optimizes the microstructure, significantly enhancing corrosion resistance and mechanical stability.

Electrical Discharge Machining (EDM): Achieves precise internal and external geometries within tight tolerances (±0.005 mm).

Thermal Barrier Coating (TBC): Provides thermal protection, reducing surface temperatures by ~200°C, extending component life.

Industry Case Study: Inconel 718 Downhole Drilling Components

Neway AeroTech successfully delivered custom Inconel 718 drilling components produced via vacuum investment casting and HIP processes for a major oilfield service provider. These components provided superior dimensional accuracy (±0.15 mm), high yield strength (1100 MPa), and exceptional corrosion resistance under demanding downhole conditions.

Our advanced manufacturing processes, stringent quality assurance, and material expertise ensure reliability and significantly extend component service life.

FAQs for Custom Inconel Components Manufacturing

What is the typical lead time for custom Inconel component orders?

Can you handle small-batch and prototype manufacturing for Inconel parts?

What industry certifications and quality control measures do your components meet?

Which post-processing techniques enhance the corrosion resistance of Inconel components?

Can you provide technical support on alloy selection and component design optimization?