Plastic 3D Printing Custom Parts Rapid Prototyping Service

Introduction to Plastic 3D Printing for Rapid Prototyping

Plastic 3D printing offers a cost-effective and agile solution for producing custom prototypes with complex geometries and short lead times. It is widely adopted across industries for functional testing, design validation, and low-volume pre-production.

At Neway Aerotech, our plastic 3D printing services enable fast iteration of plastic components using advanced additive manufacturing technologies tailored to your design and performance requirements.

3D Printing Technologies for Plastic Prototyping

Common Technologies and Capabilities

Technology | Layer Thickness (μm) | Surface Finish (Ra, μm) | Tolerance (mm) | Feature Resolution (mm) | Applications |

|---|---|---|---|---|---|

FDM | 100–300 | 10–25 | ±0.2 | ≥0.5 | Structural mockups, housing, jigs |

SLA | 25–100 | 2–5 | ±0.1 | ≥0.1 | Smooth prototypes, transparent models |

SLS | 80–120 | 10–15 | ±0.15 | ≥0.3 | Functional parts, snap fits, assemblies |

Suitable Plastic Materials for Prototypes

Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Impact Resistance | Main Applications |

|---|---|---|---|---|

PLA | 50–70 | 55–60 | Low | Concept models, educational tools |

ABS | 40–50 | 90–100 | Moderate | Mechanical enclosures, snap-fit parts |

PETG | 45–55 | 70–80 | High | Transparent covers, fluid reservoirs |

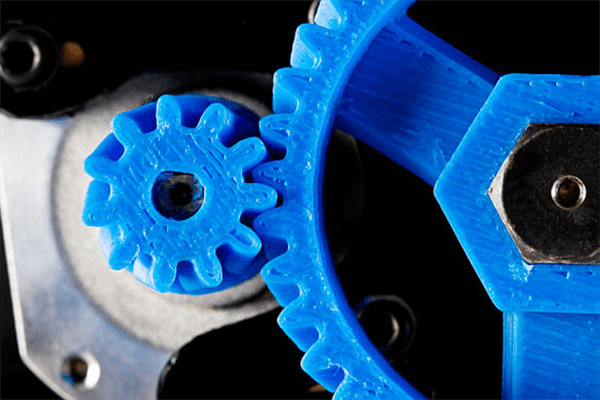

PA12 | 45–60 | 170–180 | High | Gear models, friction assemblies |

Standard Resin | 30–50 | 50–60 | Low | Aesthetic parts, jewelry, precision enclosures |

Tough Resin | 55–65 | 70–90 | Moderate | Functional prototypes, impact-resistant models |

Material Selection Strategy

PLA: Ideal for fast, low-cost visual verification and concept models that do not require mechanical load-bearing.

ABS: Suitable for structural prototypes, brackets, and fixtures with good heat resistance and machinability.

PETG: Best for applications requiring clarity, flexibility, and moderate mechanical strength under environmental stress.

PA12: Selected for engineering-grade components with high toughness and wear resistance in functional assemblies.

Standard Resin: Used for highly detailed presentation models requiring a smooth surface and fine resolution.

Tough Resin: Preferred for short-run testing of functional end-use designs needing impact and fatigue resistance.

Case Study: Rapid Prototyping of Consumer Electronics Housing

Project Background

A startup developing a new smart home sensor required a fast-turnaround plastic prototype for user testing and pre-certification. Key requirements included ±0.15 mm dimensional accuracy, transparent cover windows, and assembly-ready components with snap-fit features.

Manufacturing Workflow

Design Input: CAD files received with interlocking geometry and two-part housing design.

Material: PETG selected for the transparent window; ABS for the main shell.

Technology: SLA for high-definition covers; FDM for body structure; 100 μm layer height used.

Post-processing: Vapour smoothing for the ABS shell; UV curing and polishing for transparent PETG cover.

Assembly Testing: All clips and alignment features verified for function; shell passed snap-fit force test with no fracture.

Inspection & Validation

CMM: Tolerance within ±0.12 mm verified across mating surfaces.

Assembly Trial: Performed 10 cycle tests with no cracking or misalignment.

Visual Finish: SLA parts achieved Ra ≤ 4 μm with polished surfaces; no optical distortion detected in PETG window.

Results and Verification

The prototype met all functional and aesthetic benchmarks, allowing the client to move to user trials within 72 hours of submission. No design modifications were required after testing, significantly reducing product development lead time.

FAQs

What is the lead time for plastic rapid prototyping using 3D printing?

Can you combine different plastic materials in a single prototype build?

How accurate are the dimensions of SLA or SLS printed plastic parts?

Do you offer post-processing such as painting or texturing?

What is the maximum size of a plastic prototype you can 3D print?