粗鍛造と精密鍛造の主な違いとは?

目次

Forging Objectives and Performance Requirements

Rough Forging Characteristics

Precision Forging Advantages

Application Differences and Industry Relevance

日本語 / JA

タイトル

粗鍛造と精密鍛造の主な違いとは?

説明

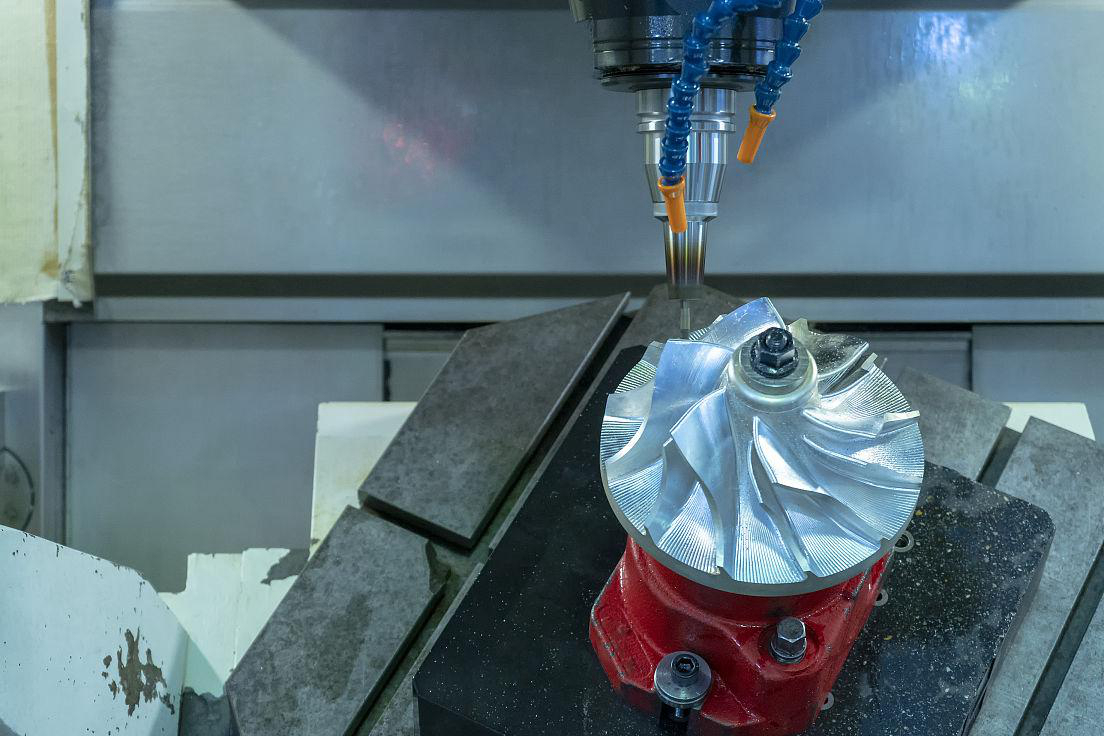

粗鍛造は精度の低い基本形状を作るのに対し、精密鍛造は結晶粒の流れを最適化し、厳しい公差と優れた高応力性能を実現します。

キーワード

粗鍛造 vs 精密鍛造, 超合金精密鍛造, 結晶粒流れ制御, HIP 後処理適性, 鍛造公差比較, 鍛造部材試験, 航空宇宙・原子力鍛造, 寸法精度鍛造

Related Blogs

専門家による設計と製造のヒントをメールで受け取りたい方は購読してください。

この投稿を共有: