一方向凝固において結晶配向を妨げる主な課題

目次

Thermal Gradient Instability

Misorientation at the Seed Interface

Freckle Formation and Solute-Driven Instabilities

Mold and Process Variations

日本語 / JA

标题:

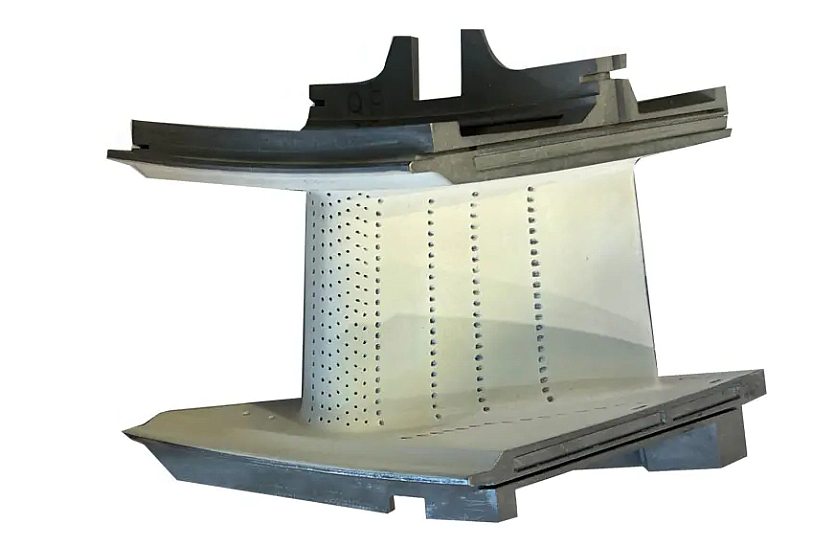

一方向凝固において結晶配向を妨げる主な課題

元描述:

一方向凝固における結晶配向は、熱的不安定性、種結晶のずれ、フレックル欠陥、鋳型内の熱流分布の変動によって阻害されます。

关键词:

一方向凝固 課題, 結晶配向 問題, 迷走粒生成, フレックル欠陥, 種結晶 配向ずれ, タービンブレード鋳造, 温度勾配制御, CMSX Rene 合金

Related Blogs

専門家による設計と製造のヒントをメールで受け取りたい方は購読してください。

この投稿を共有: