Marine Turbine Blade Superalloy Parts Company

Introduction to Marine Turbine Blade Superalloys

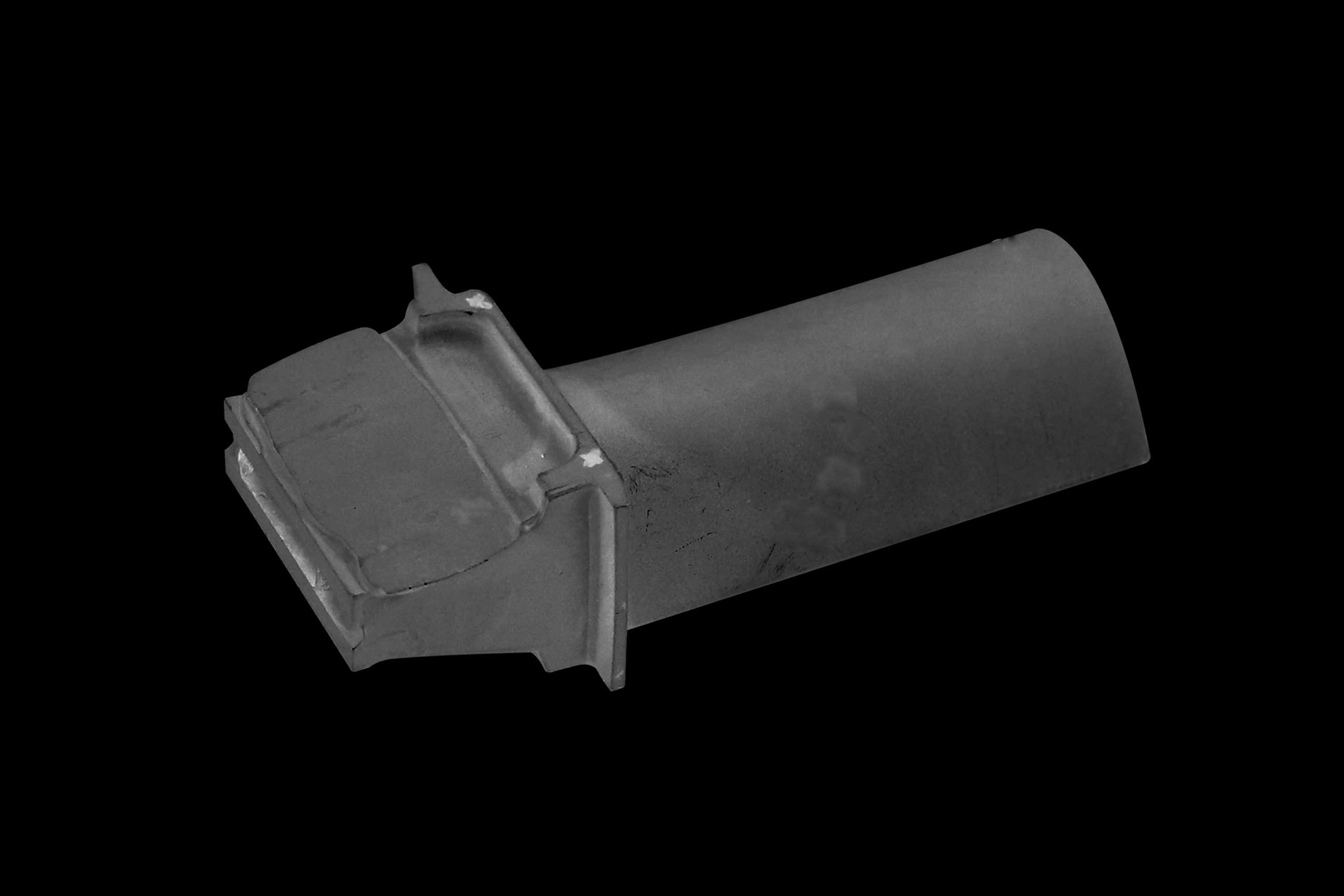

Marine turbine blades demand advanced materials capable of resisting severe corrosion, mechanical stresses, and extreme temperatures. At Neway AeroTech, we specialize in manufacturing high-performance superalloy blades designed specifically for demanding marine environments. Our expert application of vacuum investment casting and advanced machining techniques ensures exceptional accuracy, reliability, and durability of turbine blades.

With extensive marine-industry experience, we deliver customized solutions precisely engineered for superior operational performance.

Key Manufacturing Challenges for Marine Turbine Blades

Manufacturing turbine blades for marine applications involves significant technical challenges:

Corrosion Resistance: Blades must withstand constant exposure to saline conditions.

High Mechanical Strength: Essential for reliable operation, typically requiring tensile strength above 1000 MPa.

Fatigue and Creep Resistance: Ensuring blades maintain integrity under dynamic loading and elevated temperatures (up to 1000°C).

Precision Tolerances: Achieving dimensional precision within ±0.10 mm and surface finishes as low as Ra 1.6 µm.

Detailed Marine Blade Manufacturing Processes

Vacuum Investment Casting

Creation of accurate wax blade patterns.

Formation of ceramic molds and wax removal at approximately 180°C.

Vacuum casting (<0.01 Pa pressure) ensuring purity and structural uniformity.

Gradual cooling (20–35°C/hour) to reduce internal stresses and defects.

Directional and Single Crystal Solidification

Controlled thermal gradients (20–50°C/cm) ensure uniform grain structures.

Single-crystal technology eliminates grain boundaries, drastically enhancing creep performance.

Slow cooling (20–35°C/hour) minimizes defects, improving overall component integrity.

Comparison of Key Manufacturing Methods

Method | Dimensional Accuracy | Surface Finish | Efficiency | Complexity Capability |

|---|---|---|---|---|

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | Moderate | High |

Single Crystal Casting | ±0.20 mm | Ra 6.3–12.5 µm | Moderate | High |

CNC Machining | ±0.01 mm | Ra 0.8–3.2 µm | Moderate | Moderate |

SLM 3D Printing | ±0.05 mm | Ra 6.3–12.5 µm | High | Very High |

Marine Blade Manufacturing Process Selection Strategy

Vacuum Investment Casting: Optimal for complex blade geometries requiring precision (±0.15 mm) and metallurgical purity.

Single Crystal Casting: Ideal for applications demanding superior creep resistance and dimensional stability at ±0.20 mm.

CNC Machining: Perfect for achieving precise finishing features, dimensional accuracy ±0.01 mm.

SLM 3D Printing: Suitable for rapid prototyping and internal blade structures with tolerances within ±0.05 mm.

Marine Superalloy Material Analysis Matrix

Alloy Material | Tensile Strength (MPa) | Yield Strength (MPa) | Operating Temp (°C) | Corrosion Resistance | Marine Blade Usage |

|---|---|---|---|---|---|

880 | 480 | 980 | Outstanding | General marine blades | |

750 | 360 | 1038 | Exceptional | Highly corrosive environments | |

1050 | 585 | 815 | Excellent | High-load marine blades | |

1170 | 850 | 1000 | Superior | High-temp marine blades | |

1300 | 1000 | 1150 | Exceptional | Single-crystal high-temp blades | |

860 | 700 | 850 | Excellent | Wear-resistant blade applications |

Marine Blade Material Selection Strategy

Inconel 625: Chosen for excellent seawater corrosion resistance, strength (880 MPa) at operating temperatures up to 980°C.

Hastelloy C-276: Ideal for aggressive corrosive marine environments, providing outstanding resistance at up to 1038°C.

Nimonic 80A: Selected for blades requiring high mechanical performance (1050 MPa tensile strength) and moderate thermal stability.

Rene 41: Optimal for high-temperature applications, with superior tensile strength (1170 MPa) and resistance up to 1000°C.

CMSX-4: Preferred material for single-crystal blades demanding the highest creep resistance and strength at temperatures up to 1150°C.

Stellite 6: Recommended for exceptional wear resistance and durability in challenging marine conditions at temperatures up to 850°C.

Key Post-processing Techniques

Hot Isostatic Pressing (HIP): Improves internal integrity, eliminating defects at pressures ~150 MPa and temperatures ~1200°C.

Thermal Barrier Coating (TBC): Significantly reduces surface temperatures (~200°C lower), prolonging component lifespan.

Electrical Discharge Machining (EDM): Enables precise internal cooling features and geometrical accuracy (±0.005 mm tolerance).

Heat Treatment: Enhances strength, fatigue resistance, and corrosion resistance through controlled microstructure optimization.

Industry Case Study: Marine Turbine Blade Application

Neway AeroTech recently supplied Inconel 625 turbine blades to an international marine propulsion OEM. Our vacuum investment casting combined with HIP and TBC delivered exceptional dimensional accuracy (±0.15 mm), superior corrosion resistance, and dramatically enhanced operational reliability and lifespan, significantly outperforming market standards.

Our precision manufacturing capabilities and material expertise position us as a trusted industry leader for marine turbine blade components.

FAQs

What lead time can we expect for custom marine turbine blade manufacturing?

Do you support prototyping and small-volume production for marine turbine components?

What industry certifications and quality standards do your marine turbine blades meet?

Which post-processing techniques maximize durability in marine environments?

Can your team assist with alloy selection and blade design optimization for marine applications?