Thermal Barrier Coating (TBC) for Enhanced Superalloy Performance

Ceramic Insulation to Maximize Superalloy Durability

Superalloy components in turbine engines, power systems, and heat exchangers routinely operate at temperatures exceeding 1000°C. Even with excellent oxidation and creep resistance, long-term exposure causes surface degradation and structural fatigue. Thermal Barrier Coatings (TBC) provide critical thermal insulation, reducing metal surface temperatures by up to 150–200°C and significantly extending part life.

Neway AeroTech offers plasma-applied ceramic TBC systems for turbine blades, vanes, combustion liners, and exhaust hardware manufactured from Inconel, Rene, CMSX, and Hastelloy alloys.

TBC System Structure and Materials

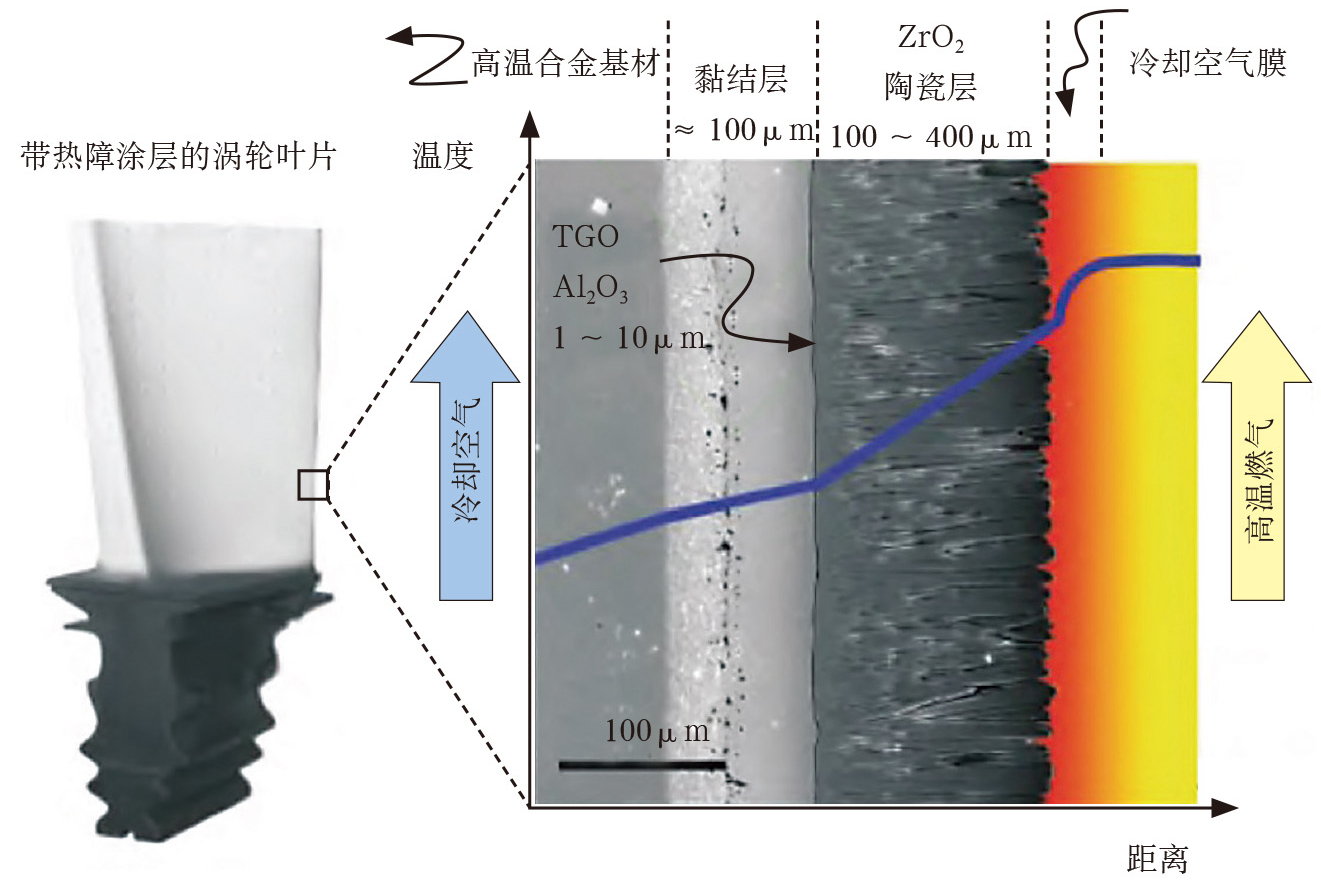

A standard TBC system includes two primary layers applied using plasma spraying or electron beam physical vapor deposition (EB-PVD):

Bond Coat (150–250 μm): MCrAlY layer provides adhesion and oxidation resistance

Top Coat (80–300 μm): Yttria-stabilized zirconia (YSZ) ceramic for thermal insulation and strain compliance

Substrate: Superalloy component cast or machined to spec, grit-blasted prior to coating

Plasma-sprayed coatings deliver 10–15% porosity for strain tolerance. EB-PVD allows feathered structures for turbine airfoil cooling.

Superalloys Commonly Protected with TBCs

Alloy | Max Temp (°C) | Coated Components | Industry |

|---|---|---|---|

1050 | Stator vanes, exhaust shells | ||

980 | HPT nozzle segments | ||

1140 | First-stage blades | ||

1175 | Combustor liners |

TBCs reduce oxidation, delay creep onset, and protect thin sections from heat-induced distortion.

Case Study: Plasma-Sprayed YSZ on CMSX-4 Airfoils

Project Background

A turbine manufacturer required TBC for CMSX-4 airfoils operating at 1100°C. Plasma-sprayed YSZ (8 wt.% Y₂O₃) was applied at 180 μm thickness, over a 200 μm NiCoCrAlY bond coat. The TBC reduced metal surface temperatures by 140°C and increased creep life by 1.8×.

Typical TBC-Coated Components and Applications

Component | Substrate | TBC Thickness | Industry |

|---|---|---|---|

Rotor Blade | Inconel 738 | 250 μm | |

Vane Segment | Rene 88 | 220 μm | |

First-Stage Blade | CMSX-4 | 180 μm | |

Combustor Panel | Hastelloy X | 200 μm |

All parts were tested for bond adhesion, porosity, thermal shock, and surface integrity.

TBC Application Challenges and Solutions

Delamination risk when thermal expansion mismatch exceeds 15 × 10⁻⁶/K between substrate and ceramic

Erosion under gas flow >30 m/s reduces topcoat thickness over time—material densification improves durability

Oxide scale formation beneath bond coat if surface prep or environment is uncontrolled

Ra ≤ 5 μm required for sealing surfaces post-TBC and must be achieved by lapping or masking

Thermal fatigue at >1000 cycles requires compliant topcoat porosity and columnar microstructure

Plasma TBC Solutions for High-Temperature Alloy Components

Plasma spraying at 45–55 kW for uniform topcoat deposition at 100–250 μm thickness

Precision masking ±0.1 mm to protect sealing and threaded features

Bond coat grit-blasting to 4–6 Ra μm and NiCoCrAlY application for oxidation control

YSZ with 8 wt.% Y₂O₃ stabilized for high thermal cycling resistance up to 1200°C

Post-coating verification via CMM, SEM, and X-ray inspection

Results and Verification

Coating Process Execution

Coatings were applied in a vacuum-sealed plasma cell with real-time thermal spray monitoring. Spray parameters adjusted per geometry and substrate.

Thermal Performance

YSZ-coated surfaces showed a 140–160°C reduction in surface temperature under 1100°C gas flow. Parts passed 1000-cycle thermal shock testing.

Surface Finishing

Critical dimensions were retained post-coating with sealing faces ground to Ra 4.5 μm. Coating thickness uniformity maintained within ±10 μm.

Inspection

CMM verified geometry. SEM confirmed porosity 10–12%, with no microcracking. X-ray inspection validated bond line integrity.

FAQs

What is the maximum operating temperature for YSZ-based TBC systems?

Can TBC be reapplied after service exposure or stripping?

What bond coat materials are commonly used for turbine superalloys?

How does TBC thickness affect component life and cooling?

Are TBCs applicable to combustor, nozzle, and vane parts?