Superalloy CNC Milling and Turning Solutions for Automotive Turbo Chargers

High-Temperature Machining Solutions for Precision Turbocharger Components

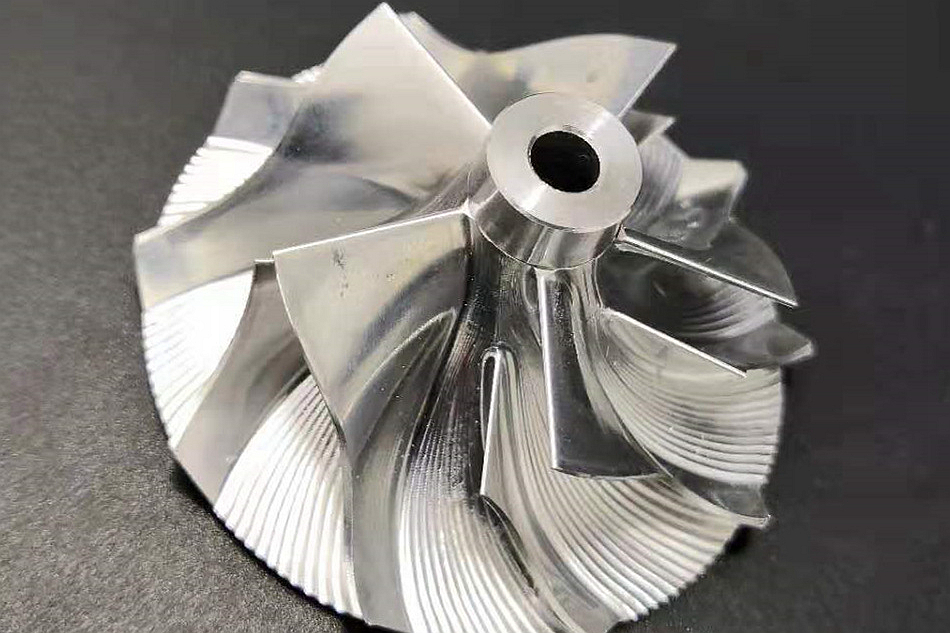

Automotive turbochargers operate under extreme thermal and mechanical stress, demanding precision-manufactured components made from high-performance superalloys. From impellers and turbine housings to exhaust flanges and compressor wheels, these parts must withstand temperatures above 1000°C and rotational speeds exceeding 100,000 rpm—requiring ultra-precise CNC milling and turning solutions.

Neway AeroTech delivers advanced CNC machining for turbocharger parts made from Inconel 625, Rene 41, Hastelloy X, and other cast or forged superalloys tailored for combustion-driven systems.

Core Technologies for Superalloy Turbocharger CNC Machining

Machining turbocharger components demands stability, repeatability, and high-speed processing across complex 3D geometries and rotationally symmetric parts.

5-axis CNC milling for turbine wheels, impellers, and curved flow surfaces

High-precision CNC turning for shaft bores, housings, and flanges with ≤ 0.005 mm runout

Coolant-through tools for machining heat-resistant alloys at high RPM

Integrated milling-turning centers for one-setup operations and reduced cycle time

All parts meet ISO/TS 16949 and IATF 16949 standards for automotive manufacturing.

Superalloys Commonly Used in Automotive Turbo Components

Alloy | Max Temp (°C) | Yield Strength (MPa) | Common Applications |

|---|---|---|---|

980 | 827 | Exhaust manifolds, turbine wheels | |

980 | 950 | Impellers, turbocharger disks | |

1175 | 790 | Turbocharger housings, nozzle rings | |

920 | 1265 | Valve guides, turbo vanes |

These alloys resist thermal creep, oxidation, and fatigue under cyclic combustion conditions.

Case Study: CNC Milling and Turning of Inconel 625 Turbo Impellers

Project Background

A Tier 1 automotive supplier requested CNC machining of Inconel 625 impellers with 12 twisted blades, 60 mm in diameter, and a 20 mm axial bore. Required tolerances: ±0.006 mm, Ra ≤ 0.4 μm on blade surfaces, and ≤ 0.01 mm runout on shaft mating interface.

Typical Turbocharger Component Models and Applications

Component | Material | Accuracy | Industry |

|---|---|---|---|

Compressor Impeller | Rene 41 | ±0.005 mm | |

Exhaust Turbine Disk | Inconel 625 | ±0.006 mm | |

Bearing Housing | Hastelloy X | ±0.010 mm | |

Turbo Flange Adapter | Nimonic 90 | ±0.008 mm |

All parts are validated for mass balance, thermal fatigue resistance, and rotational accuracy.

CNC Machining Challenges for Turbocharger Superalloy Parts

Holding ±0.005 mm runout on turned shafts and mounting interfaces

Machining Ra ≤ 0.4 μm finishes on curved blade contours

Tool wear and thermal loading during roughing of hard alloys like Rene and Nimonic

Maintaining wall thickness ≤ 1.0 mm in high-velocity flow areas

Cycle time efficiency while preserving dimensional integrity in batch production

Precision Machining Solutions for Turbocharger Components

Milling + turning centers reduce part handling and preserve bore-to-flange concentricity

CFD-based CAM strategies ensure optimized flow geometry on impeller and diffuser profiles

Tool wear monitoring with feedback to maintain ±0.006 mm on critical diameters

Coolant-fed carbide tooling for 40+ HRC alloys with feed rates up to 400 mm/min

Post-machining heat treatment for residual stress relief and surface hardness stabilization

Results and Verification

Manufacturing Methods

Parts were produced from vacuum castings and pre-machined using CNC lathes. Final finishing on 5-axis machines delivered profile tolerances under ±0.006 mm and edge radii under 0.2 mm.

Precision Finishing

Surface finish Ra ≤ 0.4 μm was achieved using contour finishing with barrel end mills. Mounting faces were turned flat to within 0.01 mm TIR.

Post-Processing

HIP and optional passivation ensured structural integrity and corrosion resistance. Components subject to extreme thermal cycles received TBC coatings as specified.

Inspection

CMM confirmed bore alignment and profile geometry. X-ray verified internal casting quality. SEM checked microstructure integrity after machining.

FAQs

What tolerances can you achieve for turbocharger rotating components?

Can you machine Inconel and Rene parts in one setup?

How do you ensure thermal balance and concentricity in turbo impellers?

What surface finish is required on blade profiles?

Do you offer batch machining for production-scale turbocharger parts?