Ti-6.5Al-1Mo-1V-2Zr (TA15)

Material Introduction

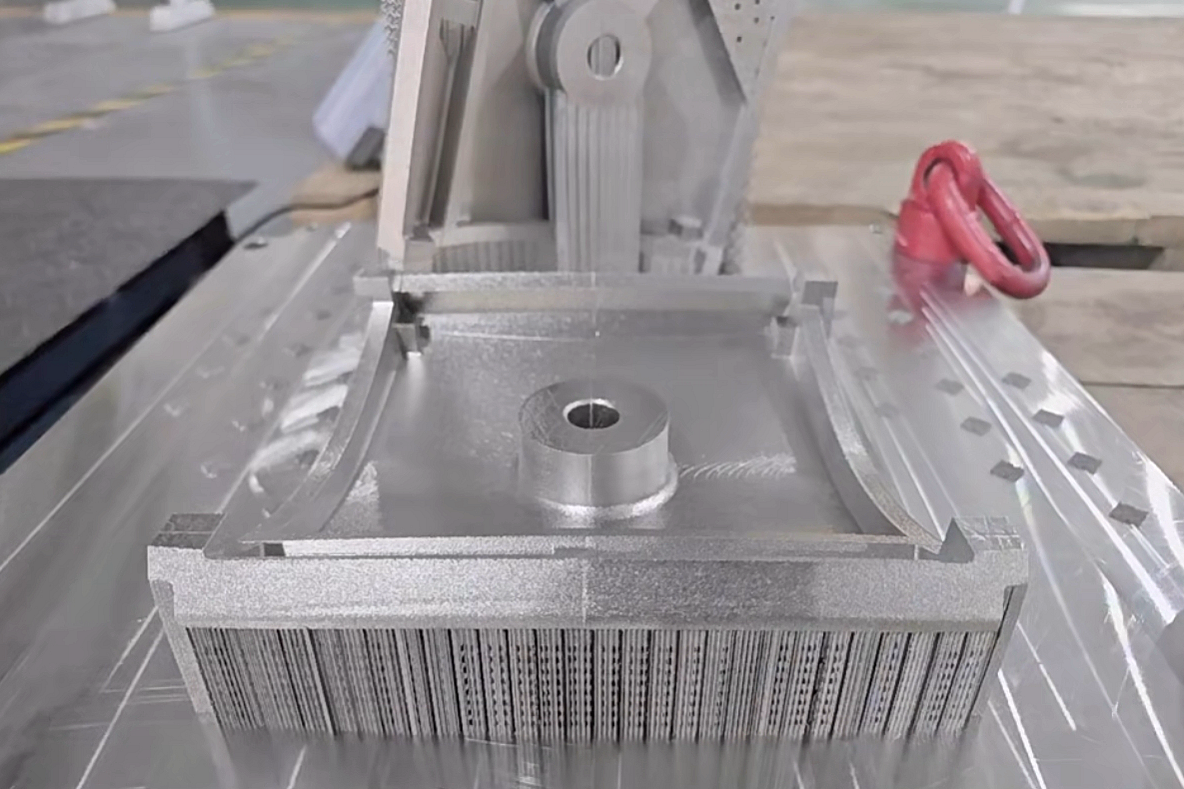

Ti-6.5Al-1Mo-1V-2Zr, commonly referred to as TA15, is a high-strength α-β titanium alloy specifically designed for lightweight aerospace parts and complex structures produced through additive manufacturing. Its composition delivers an excellent balance of specific strength, fatigue resistance, and thermal stability, enabling outstanding performance in demanding operating environments. TA15 is exceptionally well-suited for powder-bed fusion processes such as titanium 3D printing, where controlled melting and rapid cooling create fine microstructures and enhanced mechanical characteristics. The alloy maintains structural reliability at elevated temperatures and provides excellent corrosion resistance, making it a preferred choice for aircraft brackets, compressor components, and load-bearing assemblies. With the support of Neway’s advanced superalloy 3D printing capabilities, TA15 components achieve tighter tolerances and improved performance compared to traditionally machined or forged parts.

Alternative Material Options

Alternative materials to TA15 depend on specific performance requirements such as temperature capability, fatigue resistance, and cost. For general aerospace structures, Ti-6Al-4V (TC4) is the most common replacement due to its availability and cost efficiency. When superior fracture toughness is needed, Ti-6Al-4V ELI offers enhanced ductility. For ultra-high-strength applications, Ti-5Al-5V-5Mo-3Cr (Ti5553) provides significantly greater strength and hardenability. For applications requiring higher oxidation resistance, Ti-6Al-2Sn-4Zr-6Mo or Ti-6Al-2Sn-4Zr-2Mo are viable options. These alternatives allow engineers to tailor alloy selection to operating temperatures, structural loads, corrosion challenges, or manufacturing constraints.

International Naming Table

Region / Standard | Naming / Designation |

|---|---|

China (GB/T) | TA15 |

USA (UNS / AMS) | No exact equivalent; closest: Ti-6Al-2Sn-4Zr-2Mo |

Europe (EN/DIN) | No direct equivalent |

Russia | VT22L (similar class) |

Japan (JIS) | No direct equivalent |

Design Intent of TA15

TA15 was originally developed to provide higher temperature resistance and strength than conventional α-β titanium alloys while remaining cost-effective and manufacturable. Its design focus was to ensure long-term structural performance around 500 °C, improve creep resistance, and deliver strong fatigue behavior for aerospace applications. Aluminum promotes α-phase stability and high-temperature strength, while Mo and V enhance hardenability and optimize the α-β balance. Zirconium improves creep resistance and contributes to microstructural stability at elevated temperatures. With the advent of additive manufacturing, TA15 has gained prominence due to its favorable solidification behavior, ability to form refined microstructures, and suitability for producing lightweight components with complex geometries. Today, TA15 is used extensively in aerospace brackets, UAV structures, compressor housings, and load-bearing frameworks requiring superior strength-to-weight ratios.

Chemical Composition (wt%)

Element | wt% |

|---|---|

Al | 6.0–7.0 |

Mo | 0.5–1.5 |

V | 0.5–1.5 |

Zr | 1.5–2.5 |

Fe | ≤0.30 |

C | ≤0.10 |

N | ≤0.05 |

O | ≤0.15 |

H | ≤0.015 |

Ti | Balance |

Physical Properties

Property | Value |

|---|---|

Density | 4.45 g/cm³ |

Melting Range | 1600–1660 °C |

Thermal Conductivity | ~7.5 W/m·K |

Specific Heat | ~560 J/kg·K |

Elastic Modulus | 110 GPa |

Coefficient of Thermal Expansion | 9.0×10⁻⁶ /K |

Mechanical Properties (AM + Heat Treated)

Property | Value |

|---|---|

Ultimate Tensile Strength | 1000–1150 MPa |

Yield Strength | 900–1000 MPa |

Elongation | 8–12% |

Reduction of Area | 25–35% |

Fatigue Strength (High Cycle) | ~550 MPa |

Creep Resistance | Excellent at 500–550 °C |

Material Characteristics

TA15 offers an outstanding balance of tensile strength, thermal stability, and fatigue resistance, making it ideal for high-performance aerospace and industrial applications. The α-β dual-phase microstructure allows designers to achieve tailored properties through heat treatment, improving ductility and fatigue life after additive manufacturing. Compared to Ti-6Al-4V, TA15 exhibits superior strength at higher temperatures, ensuring dimensional stability and structural reliability under cyclic loads. The alloy also provides excellent corrosion resistance in marine, oxidizing, and high-temperature atmospheres. TA15 demonstrates favorable weldability, enabling hybrid manufacturing and repair. Its stiffness-to-weight ratio is exceptionally advantageous for lightweight structural design. When produced using titanium SLM 3D printing, the alloy exhibits refined microstructures, low porosity, and superior consistency, making it one of the most reliable materials for critical aerospace applications.

Manufacturing Process Performance

TA15 performs very well in powder bed fusion additive manufacturing thanks to its stable melt pool characteristics and rapid solidification behavior. The rapid cooling during printing produces fine martensitic α′ structures that can be transformed into an optimal α-β mixture through heat treatment. The result is a strong combination of toughness, ductility, and fatigue performance. In vacuum investment casting processes, TA15 requires controlled pouring conditions due to its moderate fluidity, but it remains viable for near-net-shape components. Machining TA15 requires careful heat management due to low thermal conductivity. During finishing operations or superalloy CNC machining, sharp tools and high-pressure cooling are needed to maintain dimensional accuracy. For deeper structural features, deep hole drilling provides an effective method for creating internal channels. Electrical discharge machining (EDM) is particularly effective when creating intricate shapes or thin-wall structures. Additive manufacturing provides TA15 its greatest advantage, enabling lattice structures, topology-optimized designs, and lightweight components that are difficult or impossible to produce by conventional means. Post-processing through superalloy post-processing ensures printed TA15 parts meet demanding aerospace standards.

Applicable Post-processing

TA15 responds well to multiple post-processing routes that enhance density, reliability, and mechanical properties. Hot Isostatic Pressing (HIP) eliminates internal porosity and stabilizes microstructures, significantly improving fatigue performance. Subsequent heat treatment refines the α-β microstructure, optimizing both strength and ductility. For high-temperature service, Thermal Barrier Coatings (TBC) can improve oxidation resistance. Quality verification through material testing and analysis ensures structural integrity and compliance with aerospace standards.

Common Applications

TA15 is widely used in aerospace structural components, including wing frames, cabin brackets, UAV structures, compressor housings, and hydraulic supports. Its lightweight nature and high temperature capability make it ideal for medium-temperature engine support structures and load-bearing assemblies. Beyond aerospace applications, TA15 is used in power generation, high-performance automotive parts, robotics structures, and precision mechanisms that require optimized strength-to-weight ratios. Additive manufacturing is expanding its applications to include custom medical devices and performance equipment, which require complex geometries and lightweight characteristics.

When to Choose TA15

TA15 should be selected when a titanium alloy with superior temperature resistance and strength is required beyond what Ti-6Al-4V can offer. It is ideal for applications that operate at temperatures around 500 °C and require long-term stability, strong fatigue resistance, and minimal creep deformation. Its compatibility with additive manufacturing makes it especially valuable for topology-optimized aerospace parts, lightweight structures, and complex internal geometries. Choose TA15 when components require a balance of strength, temperature capability, weldability, and corrosion resistance. It is also well-suited for applications needing reliable performance under cyclic loading. TA15 is not ideal for extreme environments exceeding 600 °C, where nickel-based superalloys are more suitable.