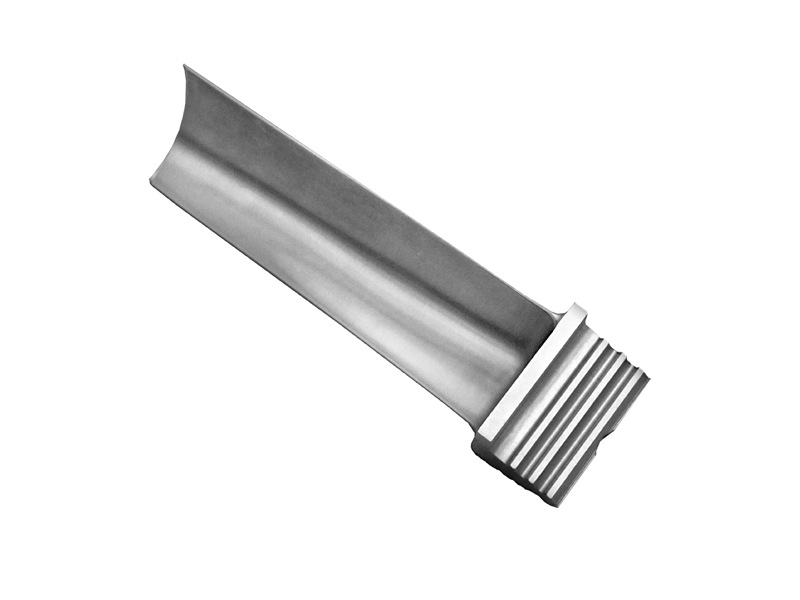

Inconel 718 Nickel-Based Alloy Superalloy Directional Casting Turbine Blades

Introduction

Turbine blades in high-performance aerospace and industrial gas turbines are subject to extreme temperatures, high rotational loads, and prolonged thermal cycling. These conditions require materials with exceptional creep resistance, fatigue durability, and oxidation stability. Inconel 718, a nickel-based precipitation-hardened superalloy, is a widely used material for turbine components due to its excellent mechanical performance up to 700°C and superb weldability.

While Inconel 718 is traditionally cast with equiaxed grain structures, advanced applications now benefit from directional casting, which aligns grains along the [001] orientation for improved creep strength and thermal fatigue resistance. Neway AeroTech provides vacuum investment casting of Inconel 718 turbine blades using directional solidification, offering enhanced component performance for aerospace, power generation, and marine turbine systems.

Core Technology of Directional Casting for Inconel 718 Turbine Blades

Wax Pattern Production High-precision wax models are produced to replicate airfoil, root, and platform geometry within ±0.05 mm tolerance.

Shell Mold Construction Refractory ceramic molds (6–10 mm) are built layer-by-layer to handle directional solidification and complex blade contours.

Grain Selector Integration Spiral grain selectors or starter blocks guide the directional growth of [001] columnar grains from root to tip, reducing transverse boundaries.

Vacuum Induction Melting Inconel 718 alloy is melted at ~1380°C under vacuum (≤10⁻³ Pa) to maintain chemical purity and prevent porosity.

Controlled Solidification The mold is withdrawn from the furnace at 2–4 mm/min through a temperature gradient, forming directionally solidified microstructures.

Shell Removal and Surface Finishing Shells are removed using high-pressure blasting and chemical cleaning to preserve airfoil precision and surface quality.

Heat Treatment and Aging Solution and aging stabilize the γ′ and γ″ phases, improving tensile strength and creep resistance.

Final Machining and Inspection EDM, CNC machining, CMM, and X-ray inspection ensure conformity to technical specifications.

Inconel 718 Material Properties in Directional Casting

Max Operating Temperature: ~700°C

Tensile Strength: ≥1240 MPa

Yield Strength: ≥1030 MPa

Creep Rupture Strength: ≥180 MPa at 650°C (1000 hours)

Fatigue Resistance: Excellent under thermal and mechanical cycling

Grain Structure: Directionally aligned [001] grains with <2° deviation

Phase Stability: Controlled γ′ and γ″ precipitation via post-casting heat treatment

Case Study: Directionally Cast Inconel 718 HPT Blades for Industrial Gas Turbine

Project Background

Neway AeroTech was selected to manufacture directionally solidified Inconel 718 blades for a high-pressure turbine (HPT) section of a 50 MW industrial gas turbine. The customer required fatigue-resistant blades capable of operating at 670°C for continuous base-load operation.

Application Examples

High-Pressure Turbine Blades (Aero-Derivative Engines) Exposed to rapid thermal transients and high centrifugal loads.

Power Generation Turbine Airfoils Operate under sustained thermal loads with minimal downtime for maintenance.

Marine Gas Turbine Rotors Used in salt-laden, corrosive environments with thermal shock resistance requirements.

Manufacturing Workflow for Directionally Cast Inconel 718 Blades

Mold and Gating Optimization CFD-guided design ensures directional grain flow, reduced turbulence, and minimized porosity.

Vacuum Casting Execution Casting is performed in vacuum furnaces with precise withdrawal rate control to promote columnar grain growth.

Heat Treatment and Phase Control Solution and aging treatments refine γ′/γ″ distribution, stabilizing mechanical properties for high-cycle performance.

CNC Machining and EDM Finishing Attachment roots, sealing faces, and cooling holes are completed via CNC machining and EDM.

Final Quality Inspection Grain orientation verified via EBSD, X-ray and CMM ensure zero-defect delivery.

Key Manufacturing Challenges

Achieving consistent directional solidification in complex airfoil geometries

Preventing stray grain formation near blade root transitions

Ensuring full γ″ precipitation during aging without over-aging

Holding tight dimensional tolerances after heat treatment and machining

Results and Verification

[001] grain orientation verified across blade span with <2° deviation

Creep rupture strength ≥180 MPa at 650°C confirmed in test coupons

Dimensional tolerances held within ±0.03 mm across all critical features

100% ultrasonic and radiographic NDT compliance for all castings

Mechanical and metallurgical certification provided per AS9100 and NADCAP standards

FAQs

Why use directional casting for Inconel 718 turbine blades?

What advantages does Inconel 718 offer over other superalloys?

How is grain orientation controlled during directional casting?

Can directional Inconel 718 blades be repaired after service?

What inspection methods are used to verify casting integrity?