Carbon-Fiber Reinforced Filament

Material Introduction

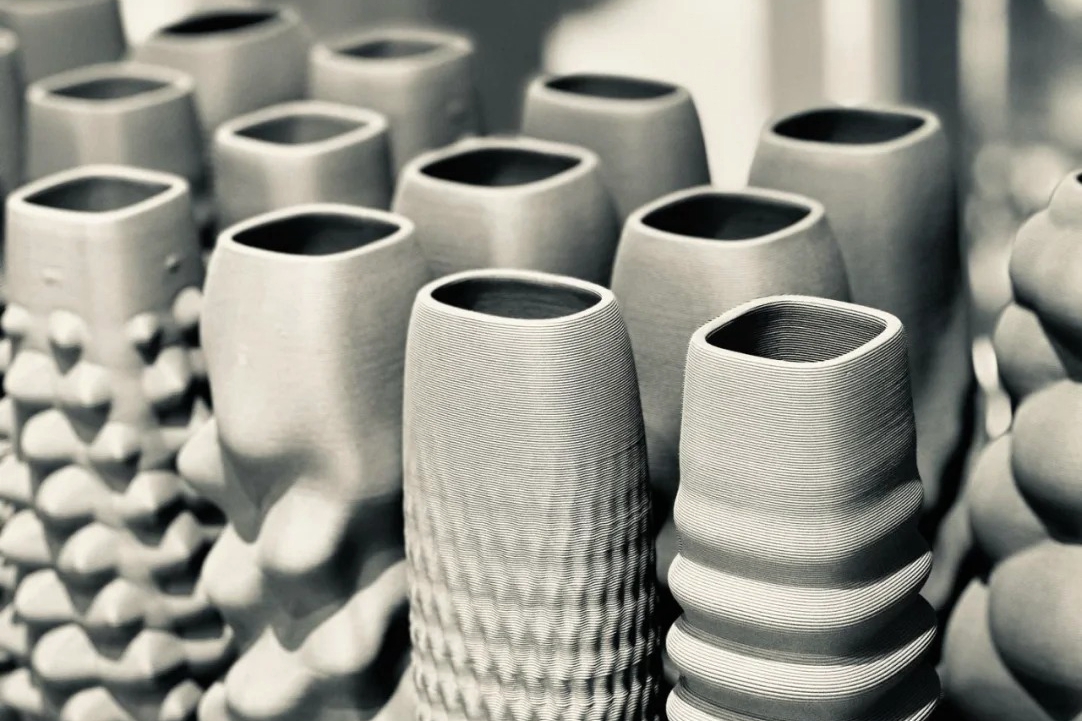

Carbon-fiber reinforced filament is an advanced composite material engineered for high-performance plastic 3D printing. By combining a thermoplastic matrix with finely chopped carbon fibers, it delivers significantly higher stiffness, strength, and dimensional stability compared with standard polymers. This filament is particularly suited for functional prototypes, jigs and fixtures, structural brackets, and lightweight end-use components where rigidity and temperature resistance are critical. When processed through Neway AeroTech’s industrial-grade 3D printing service and optimized build parameters, carbon-fiber-reinforced filament offers excellent layer adhesion, reduced warping, and a clean, matte surface that hides layer lines. The low density of the composite offers an outstanding strength-to-weight ratio, making it ideal for aerospace, motorsport, and automation components that require lightweight design without compromising mechanical performance.

Alternative Material Options

When project requirements fall outside the ideal operating window of carbon-fiber reinforced filament, several alternative materials are available. For general-purpose prototypes prioritizing ease of printing and low cost, standard thermoplastics such as PLA or PETG are suitable. When higher toughness and impact resistance are required, unfilled or glass-filled nylon filaments provide better ductility and fatigue life. For applications requiring extreme heat and chemical resistance, high-performance polymers such as PEEK or other advanced plastics may be more suitable. Where plastic composites cannot deliver sufficient stiffness or service temperature, metal options like aluminum 3D printing or superalloy 3D printing provide metal-level strength and long-term stability in highly loaded or high-temperature environments.

International Equivalent / Comparable Grade

Country/Region | Equivalent / Comparable Grade | Specific Commercial Brands | Notes |

Global | PLA-CF (Carbon-Fiber PLA) | Bambu Lab PLA-CF, Elegoo PLA-CF, ColorFabb XT-CF20 | Easy to print, high stiffness, suitable for general engineering prototypes. |

Global | PA6/PA12-CF (Nylon-CF) | NylonX, PA6-CF20, PA12-CF engineering filaments | High tensile strength and HDT; ideal for jigs, brackets, and structural parts. |

Global | PETG-CF | Industrial PETG-CF grades from major filament manufacturers | Balanced rigidity and toughness; improved chemical resistance over PLA-based CF. |

Global | HTN/PEEK-CF | High-temp nylon-CF and PEEK-CF composites | Very high heat resistance for demanding industrial and under-hood components. |

Global | Standard Fiber-Reinforced Filaments | Glass-fiber reinforced PA, PETG, PC | Alternative reinforcement where carbon fiber is not required or cost-constrained. |

Design Purpose

Carbon-fiber reinforced filament was developed to bridge the gap between easy-to-print thermoplastics and metal components in functional applications. By integrating a controlled fraction of short carbon fibers into engineering polymers, it significantly increases stiffness, tensile strength, and heat resistance while maintaining FFF/FDM printability. The material is designed for parts that must hold tight tolerances under load, resist creep, and retain dimensional stability under elevated temperatures. Typical use cases include end-of-arm tooling, inspection fixtures, structural brackets, drone frames, and lightweight housings that benefit from a high strength-to-weight ratio. In many situations, carbon-fiber reinforced filament enables engineers to replace traditional aluminum or sheet-metal parts with printed composites, especially when combined with Neway AeroTech’s optimized carbon-fiber reinforced filament printing parameters and professional process control.

Chemical Composition

Component | Polymer Matrix | Carbon Fiber | Impact Modifiers | Stabilizers / Additives |

Typical Content (wt.%) | 60–80% (PLA, PA, PETG, or other thermoplastics) | 15–30% chopped carbon fiber | 0–5% (depending on base polymer) | ≤5% (flow modifiers, coupling agents, colorants, processing aids) |

Physical Properties

Property | Density | Heat Deflection Temperature (HDT @ 0.45 MPa) | Thermal Conductivity | Electrical Behavior | Thermal Expansion |

Typical Value | ~1.20–1.35 g/cm³ (depending on matrix) | ~80–155°C for PLA-CF to PA-CF grades | ~0.25–0.40 W/m·K | Semi-insulating; not designed as an ESD material | ~30–60 µm/m·°C (lower than unfilled polymers due to carbon fiber) |

Mechanical Properties

Property | Tensile Strength (XY) | Tensile Modulus | Elongation at Break | Flexural Strength | Flexural Modulus | Impact Strength |

Typical Value | ~50–110 MPa | ~4,000–9,000 MPa | ~1.5–3.0% | ~90–150 MPa | ~6,000–10,000 MPa | ~8–20 kJ/m² (notched Charpy or Izod, depending on grade) |

Key Material Characteristics

High stiffness and rigidity compared with standard thermoplastics, enabling metal-like behavior in many applications.

Excellent strength-to-weight ratio, allowing lightweight replacement of aluminum brackets and fixtures.

Improved heat resistance; suitable for elevated service temperatures within the limits of the base polymer.

Reduced warpage and shrinkage thanks to the carbon fiber network, enhancing the dimensional stability of long parts.

A matte surface finish that minimizes visible layer lines, providing a professional and technical appearance.

Good fatigue resistance for repeated loading in jigs, grippers, and robotic tooling.

Stable mechanical performance when printed under controlled conditions via professional plastic 3D printing systems.

Lower coefficient of thermal expansion than unfilled polymer, improving fit-up with metal assemblies.

Can be machined, drilled, and tapped after printing with proper tooling, enabling hybrid manufacturing strategies.

Compatible with a variety of base resins (PLA, PA, PETG, HTN), allowing tuning of toughness versus stiffness.

Manufacturability And Post Process

FFF/FDM 3D printing: Primary process for carbon-fiber reinforced filament using Neway AeroTech’s industrial 3D printing service.

Optimized printing parameters – controlled nozzle temperature, bed temperature, and drying cycles for carbon-fiber composites.

Support for complex geometries, internal channels, and lattice structures that are difficult to machine conventionally.

Post machining: Local milling, drilling, and countersinking to refine interfaces and tolerance-critical features.

Tapping and threaded inserts: Use of heat-set or mechanically installed inserts to create robust threaded joints.

Precision trimming and sanding to refine edges, deburr features, and achieve specified surface roughness.

Bonding and assembly with other polymer or metal parts using structural adhesives or mechanical fasteners.

Hybrid builds where printed carbon-fiber components are combined with metal elements produced by aluminum 3D printing or titanium alloy casting.

Suitable Surface Treatment

Progressive sanding and bead-blasting (where appropriate) to achieve smooth, uniform matte textures.

Primer and painting: Application of adhesion-promoting primers followed by industrial coatings for color and UV protection.

Clear coat finishes to seal the surface, improve chemical resistance, and reduce fiber exposure in high-contact areas.

Epoxy or resin infiltration for selected regions to enhance surface hardness and reduce porosity.

Laser marking for high-contrast logos, part IDs, or serial codes on suitable base polymers.

Local sealing of edges or threads to improve moisture resistance on hygroscopic base polymers such as nylon.

Common Industries and Applications

Aerospace and aviation brackets, cable guides, sensor mounts, and non-flight-critical structural components.

Automotive jigs and fixtures, interior brackets, under-hood clips, and lightweight enclosures.

Power generation tooling, inspection fixtures, and support components near warm zones.

Robotics end-effectors, grippers, and motion-system brackets require high stiffness and low mass.

Drones, UAVs, and racing platforms where stiffness and weight reduction directly impact performance.

Industrial automation components, test fixtures, and assembly aids that demand repeatable dimensional accuracy.

High-performance sporting goods prototypes, custom mounts, and mechanical subassemblies requiring rapid iteration.

When to Choose This Material

High stiffness requirements: When parts must be significantly stiffer than standard PLA or PETG components.

Functional load-bearing parts: Suitable for designs targeting tensile strength in the ~50–110 MPa range (XY direction).

Weight-sensitive designs: Ideal where lightweight structures outperform aluminum or steel in system-level performance.

Elevated temperature environments: Especially when using PA-CF or HTN-CF composites with HDT up to ~150°C.

Dimensional stability: Recommended for long, thin, or cantilevered parts with strict deflection and warpage limits.

Stiff fixtures and tooling: Excellent for jigs, nests, and inspection gauges that require low creep under moderate loads.

High-cycle fatigue: Appropriate where components undergo repeated loading and unloading during production or operation.

Rapid metal replacement: When lead time or cost constraints favor composite 3D printing over machined aluminum.