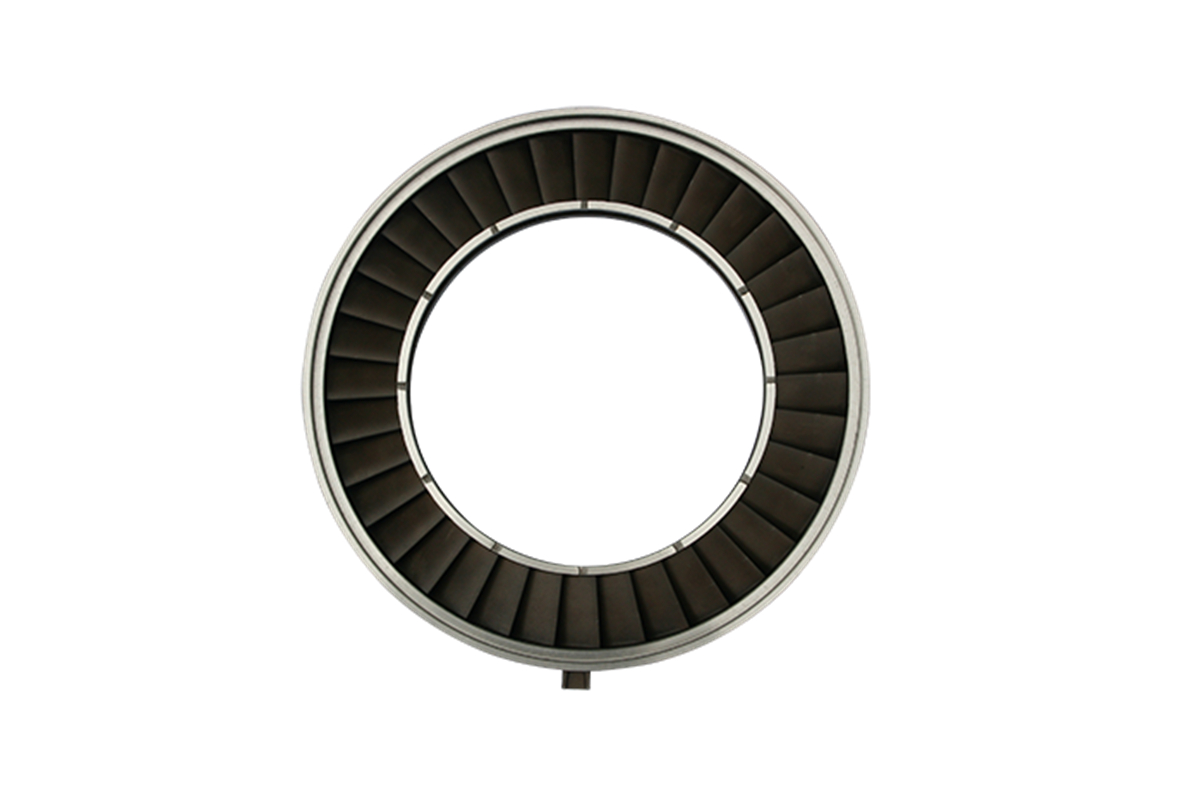

Rene N5 Precision Casting Jet Engine Turbine Nozzle Ring Components Workshop

Introduction

Rene N5 is a single-crystal nickel-based superalloy engineered for use in the hottest sections of jet engines, offering superior creep resistance, thermal fatigue stability, and oxidation resistance at temperatures exceeding 1150°C. As a specialized precision casting workshop, we manufacture Rene N5 turbine nozzle ring components using equiaxed and directional casting techniques, achieving dimensional accuracy within ±0.05 mm and microstructural integrity tailored for jet engine hot-section assemblies.

Our Rene N5 nozzle rings support next-generation turbine engines with long-term durability and cycle resistance under extreme temperature and pressure conditions.

Core Technology: Precision Casting of Rene N5

We employ advanced vacuum investment casting and directional solidification processes for Rene N5 to achieve superior phase stability and creep resistance. The alloy is vacuum melted and cast at ~1450°C into ceramic shell molds (8–10 layers) preheated to ~1100°C. For directional components, mold withdrawal rates are controlled (1–5 mm/min) to form columnar grains or single-crystal structures. Equiaxed options are also available for non-rotating segments. All parts meet dimensional tolerances of ±0.05 mm and porosity below 1%.

Material Characteristics of Rene N5 Alloy

Rene N5 is a second-generation nickel-based superalloy specifically developed for single-crystal turbine components. It maintains excellent mechanical strength and microstructural stability under the highest operational temperatures in jet engine environments. Key properties include:

Property | Value |

|---|---|

Density | 8.6 g/cm³ |

Tensile Strength (at 980°C) | ≥1100 MPa |

Creep Rupture Strength (1000h @ 1093°C) | ≥180 MPa |

Operating Temperature Limit | Up to 1150°C |

Oxidation Resistance | Excellent |

Phase Stability | Superior at elevated temperatures |

Rene N5’s stability at high temperature makes it ideal for nozzle ring components in the combustor-turbine interface, where flow control and heat exposure are extreme.

Case Study: Jet Engine Turbine Nozzle Ring Project

Project Background

A major aerospace engine OEM required turbine nozzle ring segments for the high-pressure turbine of a widebody engine platform. Components had to endure continuous exposure to exhaust gas temperatures >1100°C with precise aerodynamic alignment. We supplied Rene N5 castings using directional solidification and CNC machining to meet AMS 5400 requirements and NADCAP quality standards.

Typical Jet Engine Nozzle Ring Applications

HPT Nozzle Ring Segments (e.g., GE90, PW4000): Rene N5 segments provide oxidation resistance and creep strength at turbine inlet zones exposed to 1100–1150°C combustion gases.

Turbine Inlet Guide Vanes: Static directional vanes that guide airflow into the first turbine stage, requiring phase stability and low-cycle fatigue resistance.

Single-Crystal Inner Shrouds: Monocrystalline castings used in rotating interface environments to eliminate grain boundary creep and distortion.

Frame Transition Nozzles: Fixed segments supporting structural flow transition between the combustor and turbine core.

These components are critical to maintaining flow alignment, structural integrity, and efficiency in modern jet engine platforms.

Manufacturing Solutions for Rene N5 Nozzle Ring Components

Casting Process High-precision wax patterns are invested into ceramic shells. Vacuum melting at ~1450°C is followed by directional solidification using controlled withdrawal in a Bridgman furnace for columnar or single-crystal grain orientation. Equiaxed casting is used where permitted. Controlled cooling prevents microcracking and ensures phase uniformity.

Post-processing Hot Isostatic Pressing (HIP) at ~1190°C and 100 MPa reduces residual porosity. Heat treatment is applied to enhance γ′ phase distribution and long-term creep performance.

Post Machining CNC machining finalizes seal faces, alignment tabs, and mounting features. EDM is applied for precise edge geometry, and deep hole drilling is used for film-cooling hole placement.

Surface Treatment Thermal barrier coatings (TBC) using APS or EB-PVD are applied to reduce thermal load. Aluminide coatings are available for oxidation protection in uncooled areas.

Testing and Inspection Parts are inspected using X-ray NDT, CMM dimensional validation, high-temperature tensile testing, and metallographic analysis for grain structure and γ′ phase evaluation.

Core Manufacturing Challenges

Achieving directional or single-crystal grain orientation in thin-walled nozzle ring segments.

Controlling cooling hole geometry and position without thermal cracking.

Maintaining phase stability and oxidation resistance during 1000+ operating cycles at 1100°C+.

Results and Verification

Dimensional tolerances within ±0.05 mm verified by 3D CMM scanning.

Porosity <1% confirmed by post-HIP X-ray inspection.

Creep rupture strength ≥180 MPa at 1093°C validated by 1000-hour test.

γ′ phase consistency and oxidation resistance confirmed after 1000 thermal cycles at 1150°C.

FAQs

Why is Rene N5 the optimal material for turbine nozzle ring components in jet engines?

What are the differences between equiaxed, directional, and single-crystal castings for Rene N5?

How do you ensure cooling hole accuracy in complex nozzle ring geometries?

Can Rene N5 nozzle rings be customized for different jet engine models?

What inspection standards and certifications does your workshop follow for Rene N5 aerospace parts?