High-Temperature Alloys Nimonic 81 Guide Vanes Lost Wax Casting Company

Introduction

Nimonic 81 is a nickel-chromium alloy enhanced with molybdenum and titanium, designed for superior strength, creep resistance, and oxidation resistance at temperatures up to 870°C. With a tensile strength of ~960 MPa and excellent fatigue resistance, it is widely used for guide vanes operating in the high-temperature sections of gas turbines.

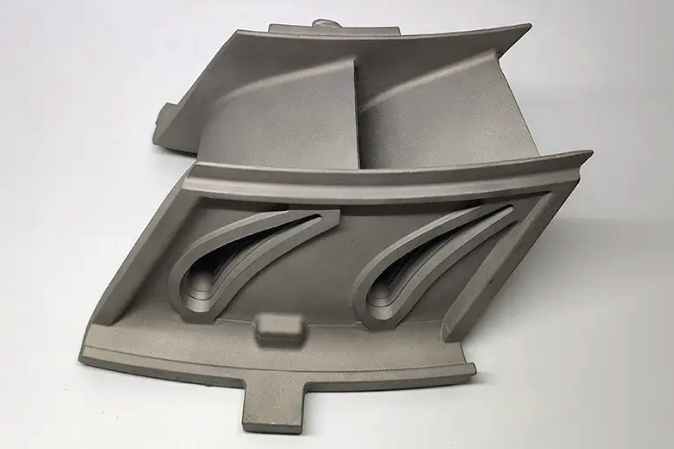

At Neway AeroTech, we specialize in manufacturing Nimonic 81 guide vanes through precision lost wax (vacuum investment) casting, ensuring high dimensional accuracy, excellent surface quality, and optimal metallurgical consistency for aerospace and industrial turbine applications.

Key Manufacturing Challenges for Nimonic 81 Guide Vanes

Precise chemical composition control (Ni ≥60%, Cr ~25%, Mo ~6%, Ti ~2.5%) for thermal and mechanical stability.

Managing controlled cooling rates (~5–8°C/min) to form fine equiaxed grains.

Achieving tight dimensional tolerances (±0.05 mm) critical for aerodynamic efficiency.

Producing superior surface finishes (Ra ≤1.6 µm) to minimize aerodynamic drag.

Lost Wax (Vacuum Investment) Casting Process for Nimonic 81 Guide Vanes

The production process includes:

Wax Pattern Fabrication: Precision wax models ensuring ±0.1% dimensional repeatability.

Shell Building: Application of multiple ceramic slurry and zircon sand layers for high mold strength.

Dewaxing: Steam autoclaving at ~150°C to cleanly remove wax without compromising mold quality.

Vacuum Melting and Pouring: Nimonic 81 alloy melted at ~1400°C and poured under vacuum (<10⁻³ Pa) to avoid oxidation.

Controlled Solidification: Slow cooling promotes fine, uniform grain structures for enhanced mechanical properties.

Shell Removal and Finishing: Ceramic removal, CNC machining, and final surface treatment to meet precise aerodynamic profiles.

Comparative Analysis of Casting Methods for Guide Vanes

Process | Surface Finish Quality | Dimensional Precision | Mechanical Strength | Creep Resistance | Cost Level |

|---|---|---|---|---|---|

Vacuum Investment Casting | Excellent (Ra ≤1.6 µm) | Very High (±0.05 mm) | Excellent (~960 MPa) | High | Moderate |

Equiaxed Crystal Casting | Good (Ra ~3 µm) | High (±0.05 mm) | Very Good (~940 MPa) | High | Moderate |

Sand Casting | Moderate (Ra ~12 µm) | Moderate (±0.5 mm) | Good (~850 MPa) | Moderate | Low |

CNC Machining from Billet | Excellent (Ra ≤0.8 µm) | Very High (±0.01 mm) | Excellent (~960 MPa) | High | High |

Optimal Manufacturing Strategy for Nimonic 81 Guide Vanes

Vacuum investment casting: Preferred for Nimonic 81 guide vanes requiring Ra ≤1.6 µm, ±0.05 mm tolerances, and optimal high-temperature mechanical performance.

Equiaxed crystal casting: Suitable for less critical turbine stages, maintaining good creep strength and oxidation resistance at reduced cost.

Sand casting: Limited to non-aerodynamic, low-load components where surface finish and creep resistance are not critical.

CNC machining from billet: Used for secondary operations requiring ultra-high precision (±0.01 mm) and Ra ≤0.8 µm finish for sealing or aerodynamic surfaces.

Nimonic 81 Alloy Performance Overview

Property | Value | Application Relevance |

|---|---|---|

Tensile Strength | ~960 MPa | High strength for turbine vane structural stability |

Max Operating Temperature | ~870°C | Sustained oxidation and creep resistance |

Fatigue Resistance | Excellent | Maintains structural integrity under cyclic loads |

Oxidation Resistance | Outstanding | Withstands aggressive exhaust environments |

Thermal Expansion Coefficient | ~13.4 µm/m·°C | Ensures dimensional stability under heat cycling |

Advantages of Using Nimonic 81 for Guide Vanes

High-temperature strength supports vane stability during continuous turbine operation.

Superior oxidation resistance extends component service life at 870°C.

Excellent fatigue resistance prevents failure under thermal cycling stresses.

Good castability allows complex aerodynamic designs without sacrificing mechanical properties.

Post-processing Techniques for Nimonic 81 Vanes

Hot Isostatic Pressing (HIP): Densifies the casting by eliminating micro-porosity, improving fatigue life and creep resistance by 15–20%.

Thermal Barrier Coating (TBC): Applies ~250 µm ceramic coating, reducing surface temperature by up to 150°C and extending service life.

Precision CNC Machining: Achieves Ra ≤0.8 µm surface finishes and ±0.01 mm tolerances for aerodynamic optimization.

Non-destructive Testing (NDT): Ultrasonic, penetrant, and metallographic testing ensure internal soundness and compliance with aerospace standards.

Inspection and Quality Assurance for Guide Vanes

Coordinate Measuring Machine (CMM): Measures key aerodynamic dimensions within ±0.05 mm tolerance.

Ultrasonic Testing (UT): Detects internal flaws and porosity.

Dye Penetrant Testing (PT): Highlights micro-cracks or casting defects at the surface.

Metallographic Analysis: Ensures grain structure meets ASTM aerospace standards.

Industry Applications and Case Study

Nimonic 81 guide vanes produced by Neway AeroTech are widely deployed in aerospace turbines, power generation turbines, and high-performance industrial gas turbines. In a major aerospace engine upgrade project, Nimonic 81 nozzle guide vanes operated flawlessly over 8,000 continuous service hours at ~850°C, achieving a 25% increase in maintenance intervals compared to previous alloy designs.

FAQs

What dimensional tolerances can Neway AeroTech achieve for Nimonic 81 guide vanes?

Why is lost wax casting preferred for Nimonic 81 guide vane production?

How does Nimonic 81 perform compared to other Nimonic alloys?

What industries commonly use Nimonic 81 guide vanes?

How does Neway AeroTech ensure the quality and durability of Nimonic 81 castings?