Superalloy Custom Tool Component Spark Erosion Machining

Introduction to Spark Erosion for Custom Tool Components

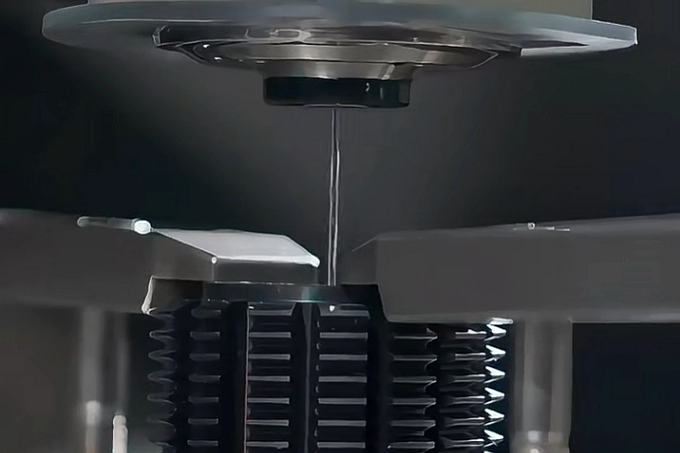

Spark erosion machining, also known as Electrical Discharge Machining (EDM), is a precise method used to manufacture intricate superalloy custom tooling components with extreme dimensional control. This non-contact technique eliminates mechanical stress during processing, making it ideal for complex geometries.

At Neway Aerotech, our superalloy EDM machining services support tool and mold manufacturers in producing high-temperature, high-hardness parts for aerospace, power, and industrial cutting applications.

EDM Machining Technology Overview

Classification of EDM Machining

EDM Process | Surface Roughness (Ra, μm) | Dimensional Tolerance (mm) | Aspect Ratio | Heat Affected Zone (HAZ, μm) | Min. Feature Size (mm) |

|---|---|---|---|---|---|

Wire EDM | 0.3–1.2 | ±0.002–±0.01 | Up to 20:1 | 2–5 μm | ~0.1 |

Sinker EDM | 0.4–2.5 | ±0.005–±0.02 | Up to 10:1 | 5–10 μm | ~0.2 |

Hole Drilling EDM | 0.5–3.0 | ±0.02–±0.05 | Up to 30:1 | 10–15 μm | ~0.1 |

Micro-EDM | 0.1–0.4 | ±0.001–±0.005 | Up to 15:1 | <2 μm | <0.05 |

Note: HAZ values depend on discharge energy, pulse duration, and dielectric properties.

EDM Machining Selection Strategy

Wire EDM: Used for fine profile contouring of precision punches, dies, and wear-resistant tooling inserts.

Sinker EDM: Ideal for 3D cavity formation in forging tools and complex custom mold geometries.

Hole Drilling EDM: Applied for internal cooling or ejection pin holes in hardened tool steels and superalloys.

Micro-EDM: Designed for ultra-small features in fine blanking and miniature progressive stamping tooling.

Material Considerations

Typical Materials for Custom Tool Components

Material | Hardness (HRC) | Wear Resistance | Thermal Stability (°C) | Machinability | Main Applications |

|---|---|---|---|---|---|

40–45 | Excellent | 870 | Poor | High-impact, wear-resistant forging or cutting tools | |

35–40 | High | 980 | Difficult | Aerospace die blocks and forming tools | |

36–42 | Moderate | 704 | Fair | Tooling for high-temperature press and mold bases | |

35–40 | High | 920 | Fair | High-load cutting tools and aerospace fastener dies | |

30–35 | Excellent | 1040 | Poor | Corrosive environment tooling inserts |

Materials Selection Strategy

Stellite 6B: Excellent for abrasive tooling requiring toughness and wear life above 10,000 cycles under impact.

Rene 41: For dies exposed to >900°C thermal stress and requiring dimensional integrity over extended forming cycles.

Inconel 718: Optimal for structural dies needing good strength, machinability, and oxidation resistance up to 700°C.

Nimonic 90: Preferred in tooling for hot working aerospace parts with intermittent shock and cyclic thermal exposure.

Hastelloy C-22: Best for corrosive media tooling such as extrusion dies and seal groove forming tools.

Case Study: Spark Erosion Machining of Custom Cutting Die Insert

Project Background

An aerospace tooling client required a set of wear-resistant forming inserts for a turbine component production line. The dies had to maintain tolerances under 900°C and repeated mechanical shock loading over 100,000 cycles.

Manufacturing Work Flow

Material Preparation: Rene 41 blank, Ø60 mm × 25 mm, solution-treated at 1065°C, aged 8 hours at 760°C.

CNC Pre-machining: 0.5 mm allowance left for final spark erosion on critical edge and cavity surfaces.

Sinker EDM Process: 3D cavity shaped with graphite electrodes; pulse-on 100 μs, spark gap 0.1 mm.

Micro-EDM: Used for vent hole and fine chamfering; 0.2 mm feature resolution, 5:1 aspect ratio.

Post Process

Stress Relief Heat Treatment at 925°C for 2 hours to reduce residual stress

HIP at 1200°C/100 MPa for 4 hours to close sub-surface porosity

Shot peening for 150% surface coverage, improving fatigue life by 30%

Surface Finishing

Precision polishing to Ra ≤ 0.4 μm on working faces using diamond paste

Passivation for corrosion protection

Edge rounding maintained within ±0.01 mm per corner radius specification

Inspection

CMM check on 35 critical points, all within ±0.003 mm tolerance

X-ray NDT showed no internal defects

SEM confirmed microstructural uniformity and clean discharge zones

Ultrasonic inspection verified soundness of entire volume

Results and Verification

Dimensional inspection confirmed profile deviation was within ±0.003 mm over cavity geometry and 2 μm flatness on mating surfaces.

HIP treatment resulted in 100% pore closure with no observable defects under 10x radiography or ultrasonic immersion testing.

Surface finish met Ra ≤ 0.4 μm requirement, and edges retained full definition after shot peening and post-polish.

SEM imaging showed no recast layer or micro-crack; spark-eroded zones were metallurgically stable and clean.

All test dies exceeded 120,000 cycles in field validation, with no observed edge wear or fracture during service life.

FAQs

What electrode materials are best for spark erosion of superalloy tooling components?

Can spark erosion be used to finish hardened tool steels above 50 HRC?

How do you ensure repeatability in deep cavity sinker EDM operations?

What post-treatment is recommended for spark-eroded forming dies?

How do you control HAZ when machining thermal-sensitive tool inserts?