Hot Isostatic Pressing (HIP) for High-Temperature Alloy Parts Enhancement

Internal Density Optimization for Thermal and Structural Performance

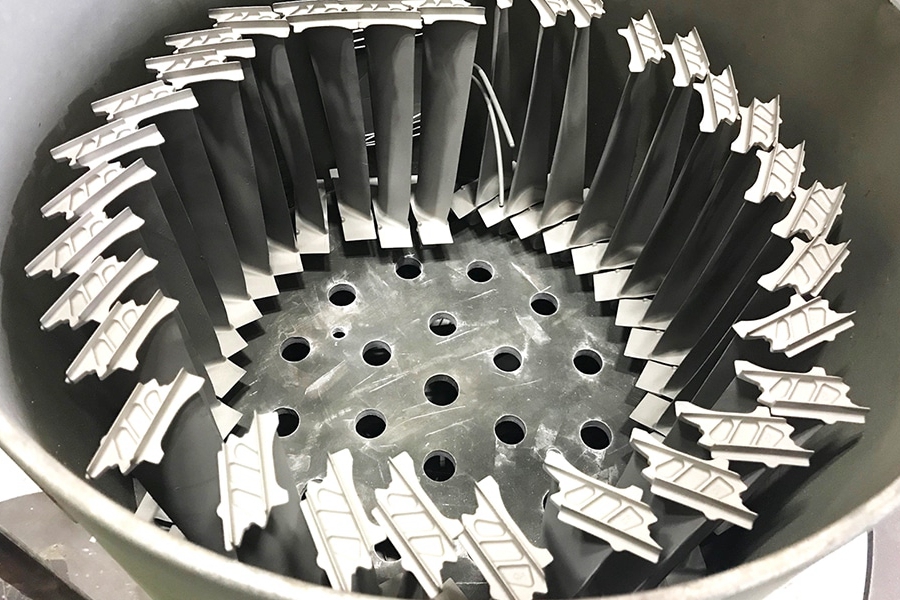

High-temperature alloy components used in aerospace, turbine, nuclear, and energy systems are subject to extreme thermal loads and fatigue. Internal porosity, often introduced during vacuum investment casting or powder metallurgy, compromises mechanical integrity and creep resistance. Hot Isostatic Pressing (HIP) is a critical post-processing step that eliminates internal voids, refines grain structures, and enhances fatigue life of superalloy parts.

Neway AeroTech provides HIP treatment for complex components made from Inconel, Rene, CMSX, and Hastelloy alloys, ensuring superior thermal, creep, and pressure resistance.

HIP Process Overview and Parameters

HIP simultaneously applies high temperature and isostatic pressure to remove porosity and improve isotropy in high-performance alloy components.

Temperature range: 900–1260°C depending on alloy

Pressure range: 100–200 MPa via inert argon gas

Duration: 2–4 hours for typical turbine or structural parts

Atmosphere: Argon in vacuum-sealed autoclave chamber

This treatment restores internal cohesion and prepares parts for subsequent heat treatment or coating processes.

Alloys and Components Commonly Treated with HIP

Alloy | Max Temp (°C) | Treated Parts | Industry |

|---|---|---|---|

704 | Rotor hubs, seal casings | ||

980 | Turbine blades, nozzles | ||

1140 | First-stage vanes, airfoils | ||

1175 | Combustion shells, sleeves |

HIP enhances structural uniformity for both equiaxed and directionally solidified castings.

Case Study: HIP of CMSX-4 Turbine Airfoil

Project Background

A CMSX-4 airfoil exhibited porosity levels of >0.4% from investment casting. The part underwent HIP at 1190°C, 170 MPa for 4 hours. Post-HIP testing confirmed density >99.9%, improved tensile strength at 1000°C, and fatigue life increased by 2.3× under cyclic thermal loading.

Typical HIP-Treated Component Models and Applications

Component | Alloy | Process Type | Industry |

|---|---|---|---|

Turbine Nozzle Segment | Rene 88 | Cast + HIP | |

Inner Combustor Ring | Hastelloy X | HIP + TBC | |

Rotor Disk | Inconel 718 | HIP + machining | |

Shroud Block | CMSX-4 | Cast + HIP |

HIP enables defect-free machining and TBC application on these heat-exposed assemblies.

Technical Benefits of HIP in Superalloy Components

Internal density >99.9% eliminates shrinkage porosity and non-metallic inclusions from cast and powder metallurgy components

Improved creep resistance extends component life under temperatures up to 1150°C in cyclic loading environments

Restores grain boundary cohesion in directionally solidified or equiaxed crystal structures

Prepares internal surfaces for reliable EDM, drilling, and CNC machining post-processing

Reduces scrap rate by up to 40% through salvage of borderline or repairable castings

HIP + Post-Processing Workflow

HIP in argon atmosphere at rated pressure and hold time

Heat treatment for hardness and strength restoration

Optional CNC machining for finishing of airfoils, housings, or flanges

TBC coatings applied for thermal protection

Final inspection including X-ray, CMM, and SEM validation

Results and Verification

Manufacturing Methods

HIP was applied in a 1.1 m diameter vessel with ±3°C control accuracy and automated gas pressurization. Full traceability maintained.

Structural Enhancement

Porosity reduced to <0.05%. Yield strength at 800°C improved by 12%. Low-cycle fatigue tests confirmed durability gains over baseline parts.

Surface and Dimensional Finishing

All parts were finish-machined post-HIP and coated where applicable. Tolerances held within ±0.01 mm. Surface prep verified for TBC adhesion.

Inspection

CMM confirmed dimensional accuracy. X-ray inspection validated internal consolidation. SEM confirmed grain boundary healing and oxide-free microstructure.

FAQs

What alloys benefit most from HIP processing?

Can HIP be used on both cast and additively manufactured parts?

How does HIP affect subsequent machining or coating steps?

What is the pressure and temperature range typically used?

How is HIP quality validated after processing?