Equiaxed Crystal Casting Gas Turbine Blade Welding Service Provider

Precision Welding for Equiaxed Superalloy Blade Repair and Assembly

Gas turbine blades cast using equiaxed crystal casting deliver robust performance under high thermal and cyclic stress. These components, typically manufactured in Inconel, Hastelloy, or Rene alloys, often require high-integrity welding for joining, tip repair, and surface build-up during maintenance and manufacturing.

Neway AeroTech provides specialized superalloy welding services for equiaxed-cast gas turbine blades used in aerospace, power generation, and industrial gas turbines. Our processes include TIG and laser welding, supported by heat treatment and non-destructive inspection to ensure structural and metallurgical compliance.

Core Welding Technologies for Cast Turbine Blades

Gas turbine blade welding requires precise thermal control and matching alloy chemistry to avoid crack formation and microstructural degradation.

TIG welding for tip restoration and leading-edge repair

Laser welding for small cross-section joints and low-distortion seams

Gas shielding and preheat control to mitigate porosity and oxidation

Post-weld heat treatment to relieve residual stress and restore mechanical properties

All welding operations comply with AS9100D, NADCAP, and OEM blade repair standards.

Common Blade Alloys and Applications

Alloy | Max Temp (°C) | Yield Strength (MPa) | Application |

|---|---|---|---|

1050 | 880 | Turbine stator vanes, rotor blades | |

1040 | 950 | High-pressure stage blades | |

1175 | 790 | Combustor transition parts | |

950 | 760 | Turbine wheel and nozzle vanes |

These alloys are selected for castability, thermal fatigue resistance, and weldability.

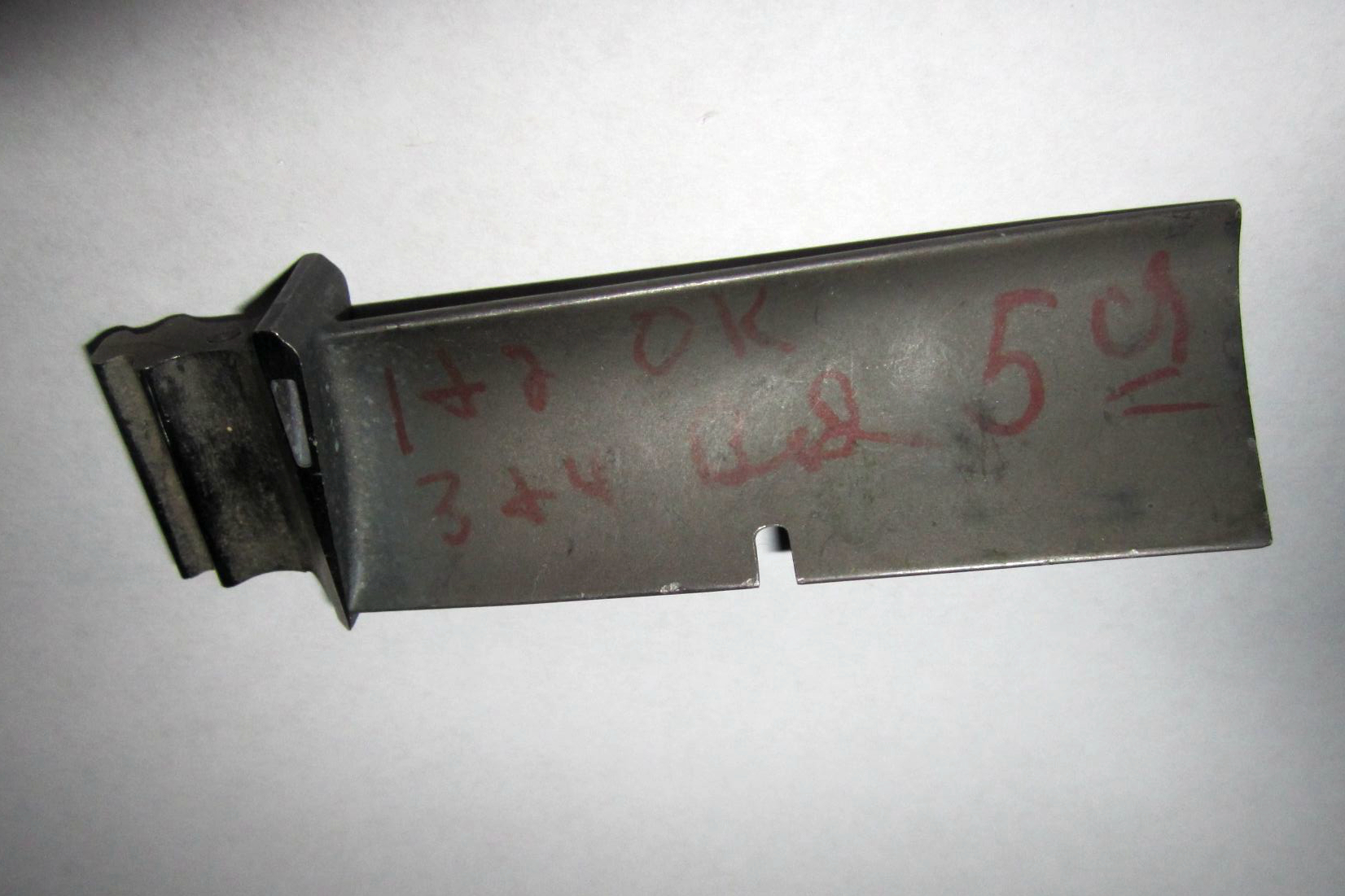

Case Study: TIG Tip Restoration of Inconel 738 Turbine Blades

Project Background

A power generation OEM submitted a batch of Inconel 738 turbine blades with tip erosion after 5,000 service hours. Using matching TIG filler metal, tip welds were applied and reshaped. Final heat treatment restored hardness and ductility, while X-ray testing confirmed full fusion.

Typical Blade Welding Applications and Industries

Component | Weld Type | Alloy | Industry |

|---|---|---|---|

Turbine Rotor Blade | TIG tip weld | Inconel 738 | |

Stator Segment | Laser seam weld | Hastelloy X | |

Blade Root Buildup | TIG filler weld | Rene 77 | |

Transition Vane | TIG + stress relief | Inconel 713C |

Each weld is tested to meet cyclic load, creep, and oxidation standards.

Welding Challenges in Equiaxed-Cast Turbine Components

Grain boundary liquation during welding can lead to cracking

Porosity and slag entrapment in small weld pools

Mismatch in CTE between weld filler and base material causes stress

HAZ embrittlement from uncontrolled phase transformation

Limited access to curved vane and trailing edge geometries

Certified Solutions for Turbine Blade Welding

TIG with matching Inconel/Rene wire to maintain metallurgical compatibility

Laser welding under inert atmosphere for crack-prone zones

Controlled preheat and interpass temperatures for ductile weld zones

Post-weld HIP and heat treatment to relieve stress and densify grain boundaries

Final machining and polishing for aerodynamic profile restoration

Results and Verification

Welding Execution

Blade tip repairs used TIG welding with Inconel 738 filler metal. Layers were built up under gas shielding with precision contour grinding. Multi-step heat treatment restored grain structure and strength.

Post-Weld Processing

Blades underwent HIP at 1030°C and passivation to improve oxidation resistance. Optional TBC coating was applied to exposed surfaces.

Inspection

X-ray ensured fusion integrity. CMM confirmed blade profile dimensions. SEM validated microstructure and HAZ grain refinement.

FAQs

What Inconel or Rene alloys are weldable in equiaxed cast form?

How are tip repairs validated on turbine blades?

Can TBC be reapplied after blade welding?

What post-weld heat treatment is required?

Do you handle both repair and new assembly welding?