304

Material Introduction

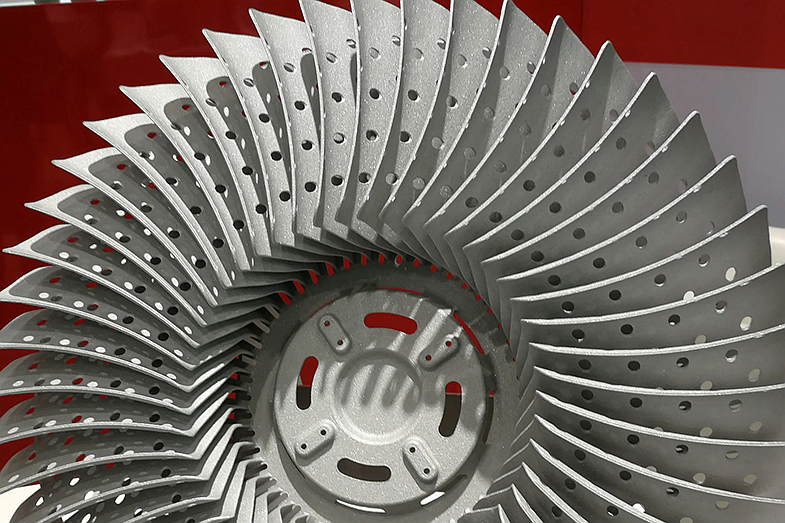

304 stainless steel is one of the world’s most widely used austenitic stainless steels, valued for its excellent corrosion resistance, good mechanical strength, and cost-effectiveness. In additive manufacturing, 304 provides a reliable pathway for producing functional metal components that require durability, hygiene, and stable performance in diverse operating environments. Through Neway’s advanced stainless steel 3D printing capabilities, 304 can be manufactured into complex geometries that are difficult or impossible to achieve via machining or traditional forming methods. This alloy demonstrates consistent layer bonding, stable melt behavior, and predictable dimensional accuracy. Combined with the broader 3D printing service, 304 supports rapid prototyping and production for mechanical housings, fixtures, brackets, kitchenware components, chemical-contact parts, and utility hardware across multiple industries.

International Naming Table

Region / Standard | Designation |

|---|---|

USA (AISI) | 304 |

UNS | S30400 |

Europe (EN) | 1.4301 |

China (GB/T) | 06Cr19Ni10 |

Japan (JIS) | SUS304 |

Alternative Material Options

Depending on operating conditions and performance needs, several stainless and non-stainless alloys serve as alternatives to 304. When higher strength and hardness are required, 17-4 PH offers superior mechanical properties and heat-treatable performance. For applications requiring enhanced corrosion resistance, 316L stainless steel outperforms other materials in chloride and marine environments. If elevated temperature strength is a priority, nickel alloys such as Inconel 625 or Hastelloy provide significantly enhanced thermal stability. For lightweight non-ferrous alternatives, aluminum 3D printing is preferred, while tool steel may be selected for wear-resistant or high-load components.

Design Intent of 304 Stainless Steel

304 stainless steel was designed to provide an economical, stable, and corrosion-resistant alloy capable of meeting the needs of food processing, architectural structures, pressure-bearing components, and chemical-handling equipment. Its composition balances chromium and nickel to stabilize the austenitic phase, providing excellent ductility, toughness, and resistance to oxidation. The alloy is also engineered to resist a broad range of acids, cleaning chemicals, and atmospheric conditions while remaining easy to form and weld. For additive manufacturing, 304 steel provides reliable printability due to its stable solidification behavior and low susceptibility to cracking. Its design intent aligns with applications requiring cleanability, hygiene, durability, and moderate strength—making it ideal for industrial equipment covers, consumer products, fixtures, and mechanical components.

Chemical Composition (wt%)

Element | wt% |

|---|---|

Cr | 18.0–20.0 |

Ni | 8.0–11.0 |

Mn | ≤2.0 |

Si | ≤1.0 |

C | ≤0.08 |

P | ≤0.045 |

S | ≤0.030 |

N | ≤0.10 |

Fe | Balance |

Physical Properties

Property | Value |

|---|---|

Density | 7.9 g/cm³ |

Melting Range | 1400–1450 °C |

Thermal Conductivity | ~16 W/m·K |

Electrical Resistivity | ~0.72 μΩ·m |

Thermal Expansion | 17.2×10⁻⁶ /K |

Modulus of Elasticity | 193 GPa |

Mechanical Properties (Printed + Processed)

Property | Typical Value |

|---|---|

Tensile Strength | 515–650 MPa |

Yield Strength | 205–320 MPa |

Elongation | 40–55% |

Hardness | ~170 HB |

Fatigue Strength | Moderate |

Impact Toughness | High |

Material Characteristics

304 stainless steel offers a robust set of characteristics that make it ideal for general-purpose 3D-printed metal parts. Its austenitic structure provides excellent ductility, enabling the fabrication of complex geometries without compromising brittleness. The alloy’s corrosion resistance is strong against most acids, alkaline solutions, cleaning chemicals, and atmospheric conditions. It also performs reliably in cryogenic environments, maintaining toughness and mechanical stability. 304 demonstrates good thermal stability, oxidation resistance up to approximately 870 °C, and smooth printability due to stable melt pool control. It is non-magnetic in its annealed condition, making it suitable for use in electronics housings and medical equipment. Its weldability and post-processing compatibility further extend its usefulness for functional prototypes, custom fittings, and industrial components. While its strength is moderate compared to heat-treatable grades, its combination of corrosion resistance, hygiene, and affordability has solidified 304 stainless steel as a universal engineering alloy.

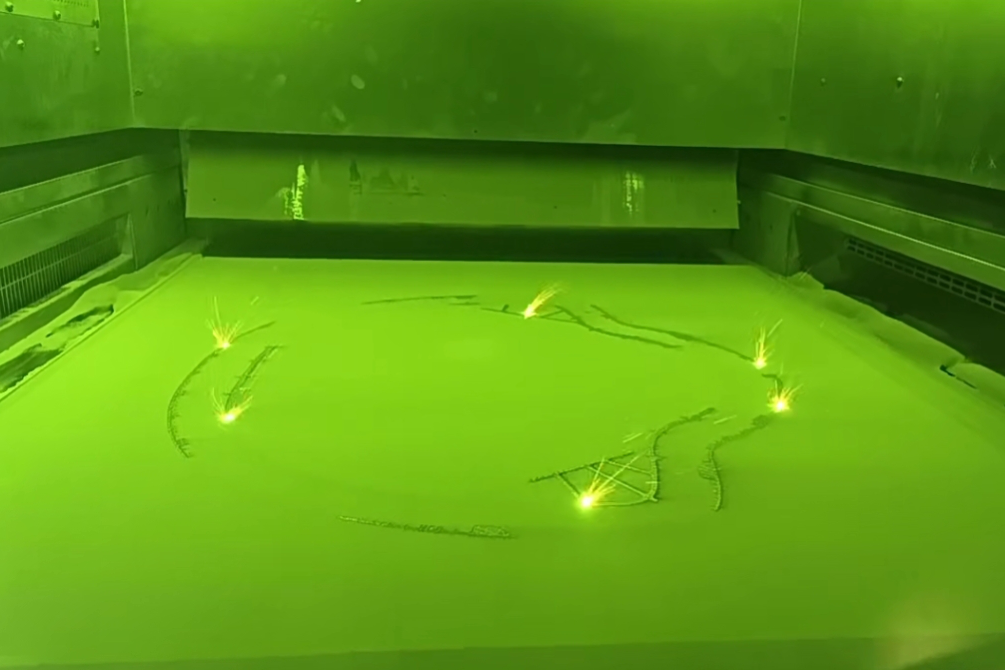

Manufacturing Process Performance

In additive manufacturing, 304 stainless steel demonstrates predictable melting, solidification, and layer adhesion, making it well-suited for laser powder-bed fusion. Its stable austenitic matrix minimizes the risk of hot-cracking during printing. Dimensional accuracy is high when appropriate temperature control and scanning strategies are applied. For casting applications, such as through vacuum investment casting, 304 offers good fluidity and resistance to hot tearing. Machining of printed or cast 304 is achievable but requires sharp tooling due to its work-hardening behavior. Finishing operations using superalloy CNC machining or EDM machining can achieve tight tolerances and refined surface qualities. In deep internal structures or long channels, precision deep hole drilling may be applied. For hybrid manufacturing, 304 welds cleanly and supports polishes, brushed finishes, and mechanical strengthening treatments.

Applicable Post-processing Methods

304 stainless steel responds well to a broad range of post-processing steps, enabling final components to meet commercial, architectural, or hygienic standards. Common finishing steps include grinding, polishing, electropolishing, passivation, bead blasting, and mechanical brushing. Heat treatments can be applied to relieve stress or optimize ductility, although 304 stainless steel is not hardenable through heat treatment. Surface enhancements, such as chemical passivation, enhance corrosion resistance, while cleaning and testing processes, including material testing and analysis, ensure part consistency. For printed parts that require high structural integrity, HIP or thermal conditioning may be employed.

Common Applications

304 stainless steel is widely used in various applications, including food processing, industrial machinery, consumer appliances, medical devices, and transportation hardware. In additive manufacturing, it is particularly useful for creating custom fixtures, brackets, housings, clamps, pipe fittings, laboratory tools, and hygienic components that must withstand corrosion and cleaning chemicals. Industries such as pharmaceutical and food, automotive, and energy benefit from 304’s combination of mechanical stability, durability, and affordability.

When to Choose 304 for 3D Printing

304 is the ideal choice when engineers require a corrosion-resistant stainless steel that strikes a balance between strength, ductility, and cost. It excels in moderate-temperature environments, food-safe applications, and general mechanical components. Select 304 for prototypes that will transition directly to production stainless steel parts, or for complex geometries requiring the corrosion resistance and hygiene properties of an austenitic alloy. Choose 304 when magnetic neutrality, easy cleaning, and resistance to industrial chemicals are essential. It is also excellent for consumer goods, mechanical housings, and medium-strength hardware. For extreme temperatures, heavy structural loads, or chloride-rich environments, grades such as 316L or nickel superalloys are more suitable. Overall, 304 is the ideal stainless steel for economical, corrosion-resistant 3D-printed components.