KBB: Equiaxed Crystal Casting Turbine Guide Vane Manufacturer

In the pursuit of cleaner energy and improved efficiency, the gas turbine industry faces growing demands for components that can withstand extreme environments. Turbine guide vanes, which control the flow of hot gases through turbine stages, play a pivotal role in achieving higher efficiency and lower emissions. As the industry transitions toward carbon neutrality, manufacturers like KBB are advancing their component technologies to meet these challenges.

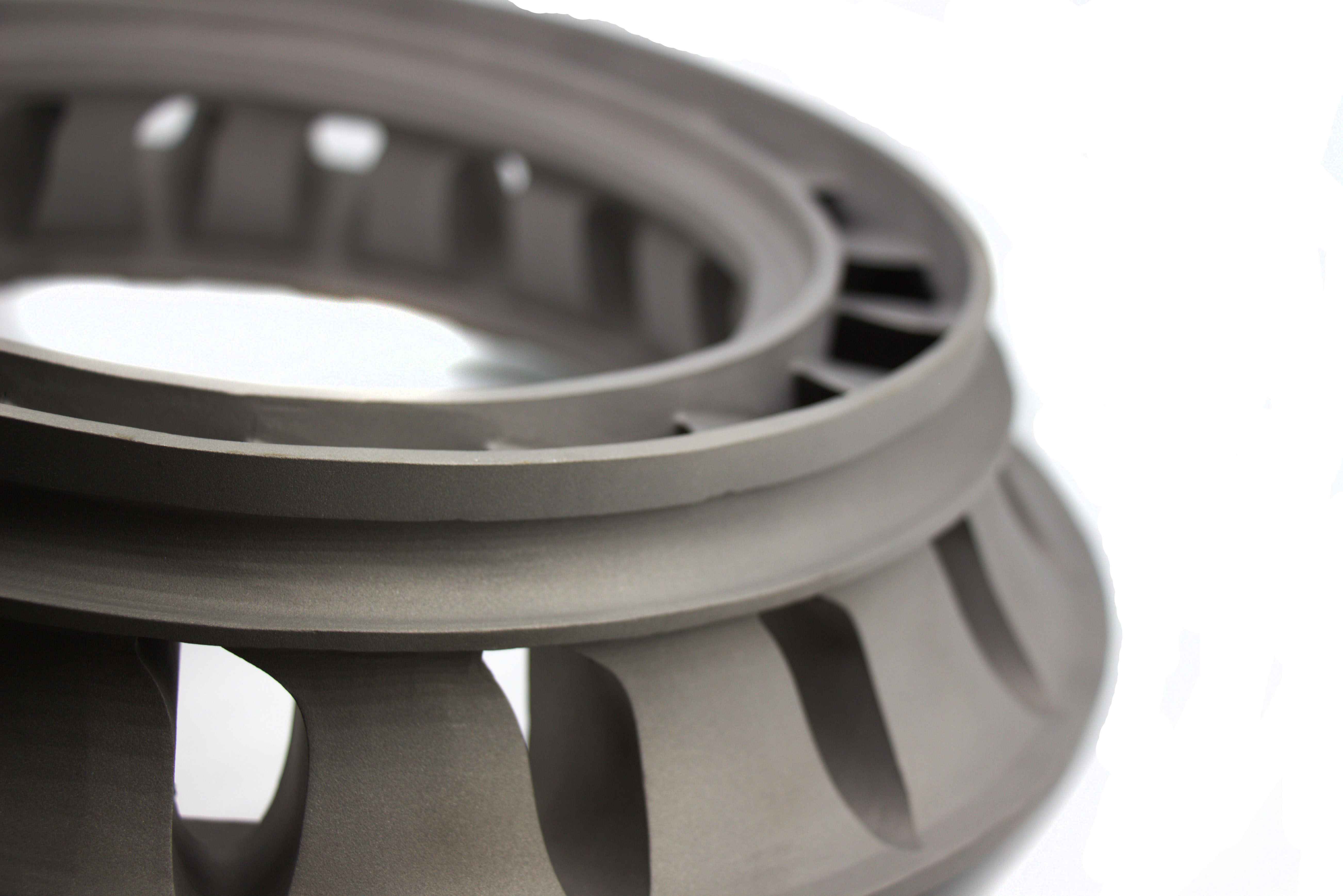

KBB’s recent initiative to localize and optimize the production of turbine guide vanes leverages equiaxed crystal casting, a proven manufacturing method that balances performance, cost, and scalability. This case study explores how KBB developed and industrialized this solution to meet the stringent requirements of modern gas turbines.

Customer Requirements and Application Context

Turbine guide vanes in KBB’s latest gas turbine models operate under temperatures exceeding 1050°C, exposed to cyclic thermal stresses, oxidation, and corrosive combustion products. The guide vanes must also maintain precise aerodynamic geometry to ensure efficient gas flow and turbine performance.

KBB specified a set of demanding requirements for this project:

High temperature tensile strength and creep resistance

Excellent thermal fatigue durability

Superior oxidation and corrosion resistance

Complex cooling passage definition and dimensional accuracy

Competitive cost structure with consistent quality in serial production

Equiaxed crystal casting was selected as the ideal process to meet these targets, offering optimized grain structure control and the flexibility to manufacture complex vane geometries.

Material and Process Design

Material Selection

Inconel 738LC was chosen for this application due to its outstanding combination of mechanical strength, creep life, and oxidation resistance at elevated temperatures. The alloy’s composition and phase stability make it highly compatible with equiaxed crystal casting.

Inconel 738LC is widely used in advanced casting superalloys for turbine components, providing a well-established performance baseline for this project.

Process Design

The manufacturing process was carefully engineered to ensure consistent quality:

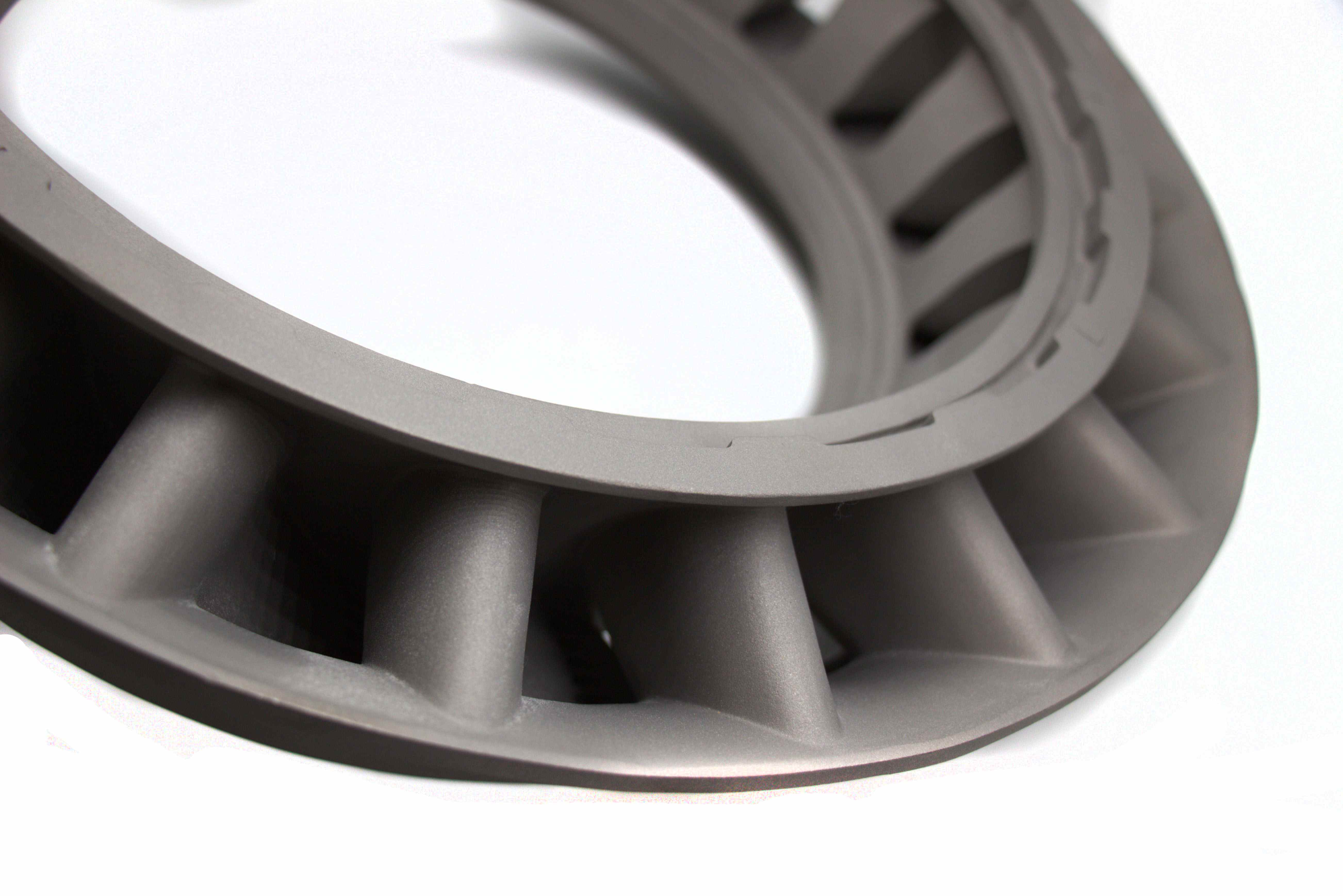

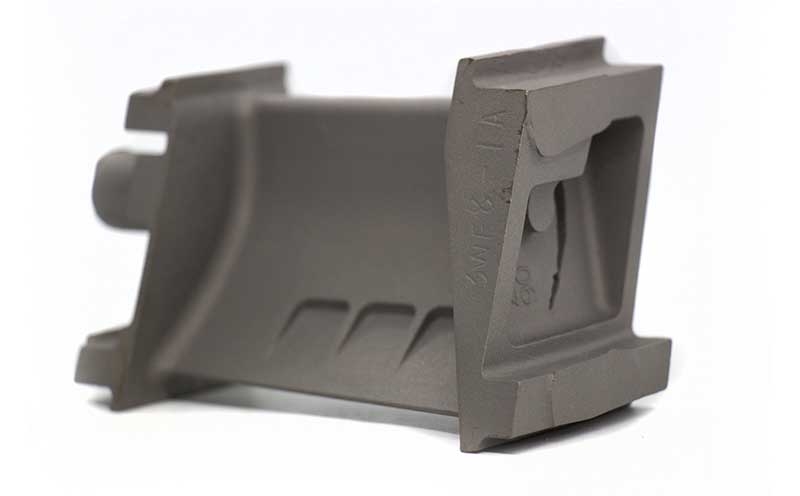

Precision wax pattern production with dimensional control for complex internal cooling channels

Advanced shell building using optimized permeability ceramic materials

Vacuum investment casting under controlled thermal gradients to promote uniform equiaxed grain growth

Tailored cooling profiles to refine grain structure and minimize residual stress

Post-cast heat treatment to stabilize microstructure and enhance mechanical properties

Every stage of the process was digitally modeled and validated to ensure repeatability and compliance with KBB’s specifications.

Overcoming Technical Challenges

Managing Geometric Complexity

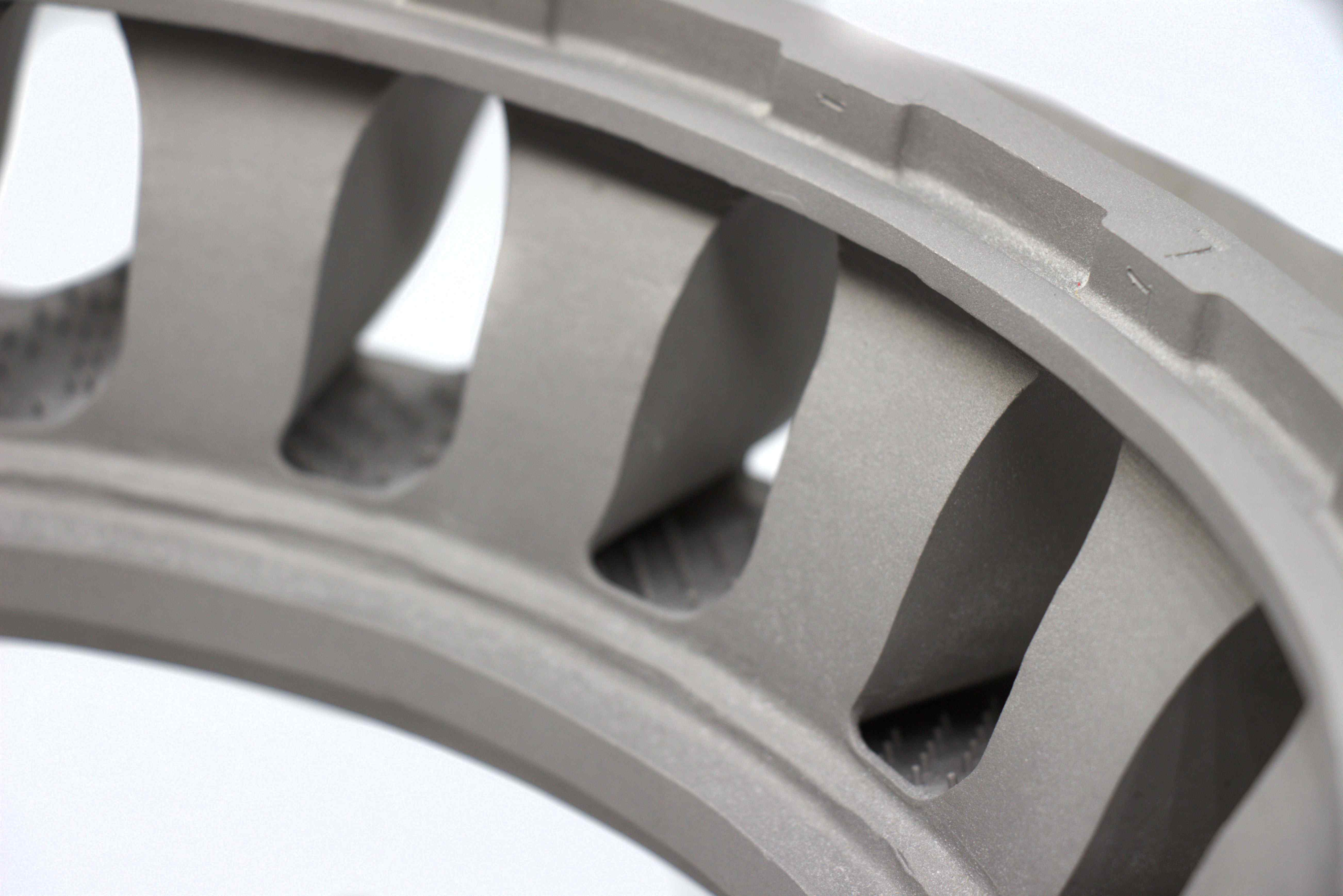

Turbine guide vanes feature intricate airfoil profiles and internal cooling networks that are critical for thermal management and efficiency. Maintaining dimensional precision across these features was a primary challenge.

To address this, the team integrated CMM checking and 3D scanning into the process flow. This enabled precise verification of critical dimensions and proactive correction of any deviations during tooling and process development.

Controlling Grain Uniformity and Defect Rates

Grain structure uniformity is essential to achieving consistent mechanical properties across the vane population. The casting parameters were optimized through extensive testing of mold preheat temperatures, pouring superheat, and cooling rates.

Non-destructive inspection using X-ray inspection and metallographic microscopy verified that internal quality consistently met or exceeded KBB’s acceptance criteria.

Integrating with Thermal Barrier Coatings

Given the harsh thermal environment, turbine guide vanes are typically coated with advanced thermal barrier coatings. Ensuring compatibility between the base alloy and the coating system required careful control of surface chemistry and roughness during casting and post-processing.

The manufacturing process was refined to produce surfaces that provided optimal adhesion and thermal performance when coated, further enhancing vane durability.

Initial Results and Quality Metrics

The pilot production runs demonstrated excellent alignment with KBB’s technical targets. Key results are presented below:

Parameter | Target | Actual Result | KBB Standard |

|---|---|---|---|

Grain size (μm) | 50-150 | 55-140 | ≤150 |

Internal defects (X-Ray Level) | ≤Level 2 | Level 1-2 | ≤Level 2 |

Surface roughness Ra (μm) | ≤3.2 | 2.9-3.1 | ≤3.2 |

Tensile strength at 1050°C (MPa) | ≥850 | 860-880 | ≥850 |

Thermal fatigue cycles | ≥3000 | >3200 | ≥3000 |

Oxidation resistance (1050°C/1000h) | Pass | Pass | Pass |

These outcomes confirmed the robustness of the equiaxed crystal casting process and its suitability for full-scale production of turbine guide vanes.

Scaling to Full Production

With pilot production successfully validated, the project progressed to full-scale manufacturing to meet KBB’s operational requirements for its latest gas turbine models.

The production line was optimized to ensure:

High process repeatability across production batches

Real-time monitoring of critical process parameters

Automated data capture and quality tracking for each component

Advanced tooling management was implemented to maintain consistent mold quality over extended production cycles. Strict control of ceramic shell properties and mold preheating protocols ensured uniform thermal behavior during casting. Continuous logging of casting temperature profiles further improved process stability.

Comprehensive Quality Assurance

To maintain the highest quality standards, each production batch underwent a multi-step verification process:

Dimensional validation using coordinate measuring machines and optical scanning

Non-destructive inspection through X-ray inspection and ultrasonic testing

Microstructural analysis using metallographic microscopy

Mechanical property testing, including elevated temperature tensile testing

Validation of coating compatibility through sample thermal barrier coating application and evaluation

This comprehensive approach ensured that each turbine guide vane met or exceeded KBB’s specifications for performance-critical components.

Field Performance and Customer Feedback

Following final qualification, the equiaxed crystal cast turbine guide vanes were integrated into KBB’s latest gas turbine prototypes and deployed in power plant field trials.

Operational data gathered from these trials revealed several notable outcomes:

Stable mechanical integrity under severe thermal gradients

Consistent dimensional stability across extended service intervals

No delamination or failure of thermal barrier coatings

Improved thermal fatigue life relative to previous-generation components

Enhanced overall turbine efficiency through precise aerodynamic control

KBB’s engineering team reported high satisfaction with the manufacturing quality and in-service performance of the components, with several customers noting tangible improvements in power plant efficiency and reduced maintenance costs.

Process Innovation and Future Development

The success of this project highlights the potential of equiaxed crystal casting as a mature and adaptable solution for high-performance turbine components. Building on this foundation, several innovation pathways are being explored:

Integration of hot isostatic pressing (HIP) to further improve component density and fatigue resistance

Application of AI-driven process control to refine grain structure uniformity

Combining traditional casting with 3D printing to enable hybrid manufacturing of highly complex features

Development of advanced high-temperature alloys such as Rene alloys for next-generation turbine platforms

By continuously investing in these innovations, KBB aims to maintain its leadership in gas turbine technology and deliver even greater value to its customers.

Industry Context and Broader Impact

This case study underscores the importance of advanced manufacturing technologies in meeting the evolving demands of the energy industry.

As gas turbines continue to play a vital role in grid stability and low-carbon energy generation, the performance of hot-section components such as turbine guide vanes becomes increasingly critical. High-efficiency turbines directly contribute to lower fuel consumption and reduced greenhouse gas emissions, aligning with global sustainability goals.

Localization of turbine component manufacturing through partnerships with precision casting specialists also supports regional supply chain resilience and fosters local industrial development.

Through collaborative engineering and relentless process optimization, KBB and its partners are delivering components that enable more efficient, more reliable, and more sustainable energy solutions.

Conclusion

The development of equiaxed crystal cast turbine guide vanes for KBB exemplifies how precision engineering, advanced materials, and optimized manufacturing processes can deliver components that meet the highest industry standards.

By combining deep technical expertise with continuous innovation, KBB has successfully localized the production of this critical component, positioning itself to support the next generation of high-efficiency gas turbines.

As the global energy landscape evolves, such collaborative efforts will continue to drive progress in performance, sustainability, and technological leadership.

FAQ

What advantages does equiaxed crystal casting offer for turbine guide vane manufacturing?

Why was Inconel 738LC selected for KBB’s turbine guide vanes?

How does vacuum investment casting improve the quality of turbine components?

What inspection methods are used to ensure the performance of turbine guide vanes?

What future innovations are planned for turbine guide vane manufacturing at KBB?