CMSX Alloy Single Crystal Castings Heat Treatment Workshop

Precision Thermal Processing for CMSX Series Turbine Blades and Vanes

Single crystal superalloys from the CMSX series—such as CMSX-4 and CMSX-10—are the foundation of modern high-performance gas turbine components. These alloys offer superior creep resistance, thermal fatigue strength, and oxidation protection. However, their mechanical properties depend heavily on precise heat treatment after single crystal vacuum investment casting to control γ′ precipitation, remove residual stress, and prevent recrystallization.

Neway AeroTech operates a dedicated heat treatment workshop for CMSX alloy turbine components, providing OEM-grade stabilization, aging, and post-HIP thermal processing. Our workshop supports aerospace, power generation, and industrial turbine customers with NADCAP-compliant thermal cycles customized for blade, vane, and segment geometries.

Core Heat Treatment Services for CMSX Superalloys

Single crystal heat treatment requires low ramp rates, inert atmospheres, and microstructure-driven aging profiles.

Stabilization at 1140–1175°C for stress relief and solidification stabilization

Two-stage aging at 870°C and 760°C to optimize γ′ morphology and mechanical strength

Vacuum or high-purity argon furnaces to prevent oxidation and preserve surface finish

Slow ramp rates (≤2°C/min) to avoid stray grain nucleation or recrystallization

Each CMSX treatment is traceable with full temperature and time profile documentation.

Common CMSX Grades and Blade Applications

Alloy | Max Service Temp (°C) | Yield Strength (MPa) | Application |

|---|---|---|---|

1140 | 980 | First-stage turbine blades | |

1160 | 1040 | High-pressure turbine vanes | |

1100 | 900 | Turbine shrouds and cooling segments | |

1120 | 910 | Nozzle guide vanes, rotor airfoils |

CMSX alloys are engineered for long-term exposure to thermal and mechanical stress in high-pressure turbine sections.

Case Study: Heat Treatment of CMSX-10 Airfoil Set

Project Background

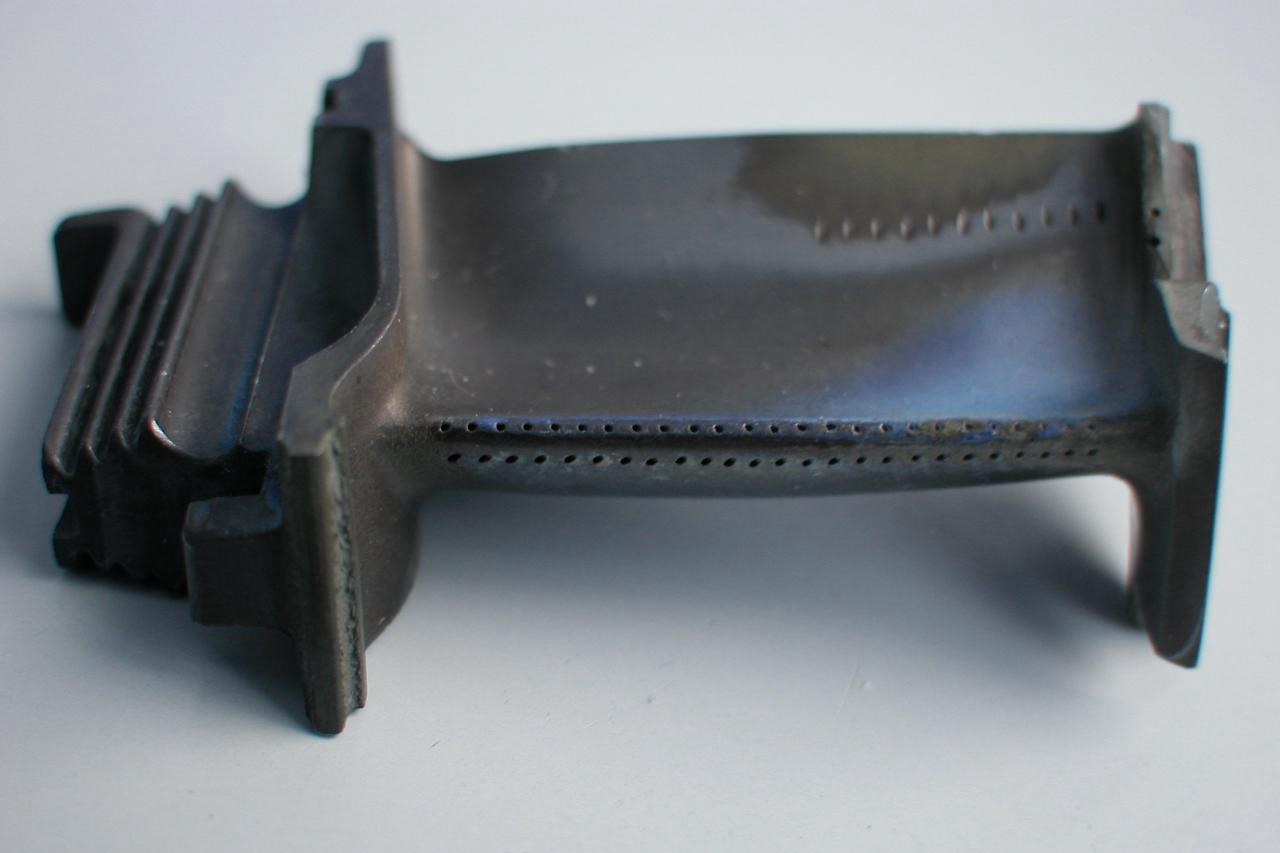

An aerospace OEM required stabilization and aging for CMSX-10 turbine blades with 3D cooling channels. The blades underwent stabilization at 1165°C for 4.5 hours followed by aging at 870°C and 760°C. SEM evaluation confirmed complete γ′ precipitation, no recrystallization, and carbide distribution consistent with OEM microstructure specs.

Treated CMSX Components and Industries

Component | Alloy | Process | Industry |

|---|---|---|---|

HPT Blade | CMSX-4 | Stabilization + Dual Aging | |

Shroud Segment | CMSX-6 | Anneal + Aging | |

Rotor Airfoil | CMSX-2 | HIP + Aging | |

Vane Cluster | CMSX-10 | Stress Relief + Aging |

All components undergo metallographic validation, hardness testing, and profile inspection post-processing.

CMSX Heat Treatment Challenges

Recrystallization risk if ramp rates or quench rates are not controlled

Incomplete γ′ formation reduces creep resistance and strength

Surface oxidation in uncontrolled furnace environments degrades component life

Distortion of platform and trailing edge due to temperature gradients

Stray grain formation compromises single crystal integrity and orientation

Technical Solutions from the CMSX Heat Treatment Workshop

Multi-zone furnace control ±2°C for thermal uniformity across blade batch

Vacuum annealing with <10⁻⁵ torr for oxidation-free results

Timed dual aging for optimized γ′ size (300–500 nm target)

Orientation-protected fixtures to avoid platform movement during heat cycles

Results and Validation

Heat Treatment Execution

Furnaces maintained uniformity within ±2°C. All blades were tracked individually with batch ID, thermal curves, and real-time logging. Total thermal cycle time: 23 hours.

Metallurgical Outcomes

Final microstructure showed homogeneous γ′ distribution across platform and airfoil. No recrystallization detected. Hardness achieved 400–430 HV with minimal variance across batches.

Final Inspection

CMM inspection confirmed no deformation beyond ±0.02 mm. X-ray inspection showed structural integrity. SEM analysis validated phase morphology and grain boundaries.

FAQs

What is the aging cycle used for CMSX-4 turbine blades?

Can CMSX-10 blades be processed without recrystallization risk?

How is γ′ precipitate size controlled during aging?

What inspection methods confirm SX integrity post heat treatment?

Do you offer HIP and heat treatment integration for CMSX castings?