Second-Generation

Material Introduction

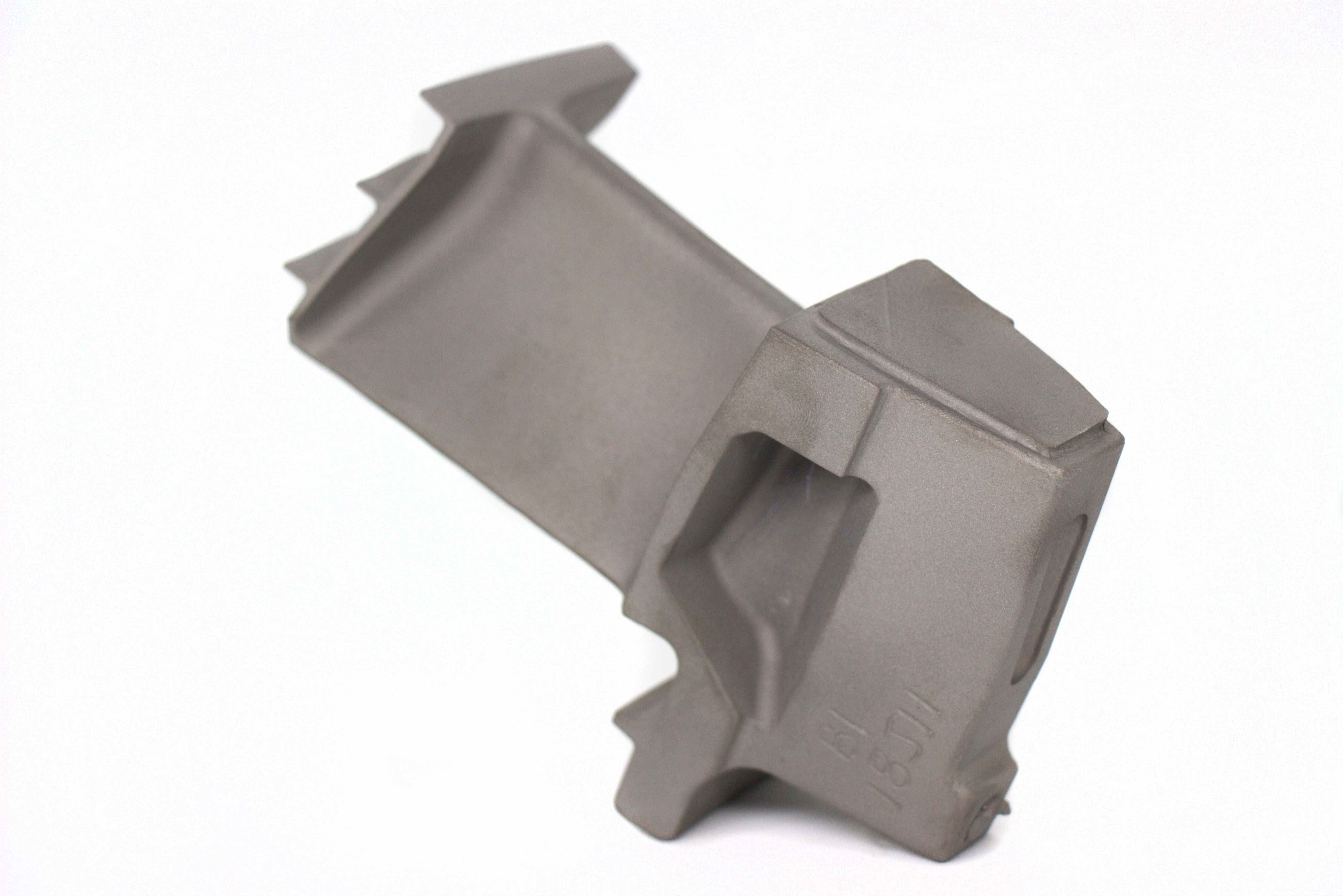

Second-generation single crystal superalloys are advanced nickel-based materials engineered for high-stress, high-temperature components produced via precision second-generation single crystal casting. Optimized for turbine blades, vanes, and hot-section hardware, these alloys incorporate carefully balanced additions of cobalt, chromium, aluminum, tantalum, tungsten, molybdenum, and rhenium to deliver superior creep resistance, fatigue life, and oxidation performance beyond first-generation grades. Using Neway AeroTech’s fully controlled vacuum investment casting platforms, directional solidification technology, and stringent process monitoring, second-generation single crystal superalloys achieve defect-minimized microstructures with precise crystal orientation and extremely low segregation. When combined with tailored heat treatment cycles and advanced thermal barrier coating systems, these alloys support higher turbine inlet temperatures, extended service intervals, and improved fuel efficiency in demanding aerospace and power generation environments.

Alternative Material Options

When design requirements fall outside the optimal window for second-generation single crystal alloys, several alternatives can be considered. For slightly lower temperature but cost-sensitive designs or legacy fleets, first-generation single crystal alloys remain a robust and economical option. Where even higher turbine inlet temperatures and extreme creep resistance are needed, advanced third-generation, fourth-generation, or fifth-generation single crystal alloys provide increased rhenium or ruthenium content for additional high-temperature strength. For components that do not require single crystal performance but still operate in hot gas paths, directional casting or equiaxed crystal casting of nickel or cobalt-based superalloys delivers strong cost–performance balance. In heavily loaded rotating disks, powder metallurgy turbine discs such as FGH96 and FGH97 offer outstanding low-cycle fatigue resistance. For rapid validation and complex cooling-channel development, superalloy 3D printing enables agile iteration before committing to full single crystal tooling.

International Equivalent / Comparable Grade

Country/Region | Representative Second-Generation Alloys | Specific Commercial Brands / Developers | Notes |

USA | Rene N5, Rene 142, PWA 1484 | Widely used second-generation single crystal families for aero and industrial gas turbines. | |

Europe | CMSX-4, CMSX-10, CMSX-11 | CMSX series by Cannon-Muskegon | Benchmark SC alloys with balanced creep strength, castability, and coating compatibility. |

Japan | TMS-75, TMS-138, TMS-162 | Developed for ultra-high temperature turbine blade operation with optimized Re and Ta content. | |

China | DD6, SC180, RR3000 | Modern second-generation SC systems tailored for large industrial and aero gas turbines. | |

Global OEM Practice | Rene 88, CMSX-486, EPM-102 | Used in various hot-section parts and as development platforms for new turbine designs. |

Design Purpose

Second-generation single crystal superalloys were developed to exceed the temperature and stress limits of first-generation SC materials while avoiding the cost and complexity of more heavily alloyed later generations. By introducing moderate rhenium content and fine-tuning refractory elements such as W, Ta, and Mo, these alloys are engineered to withstand gas temperatures approaching or exceeding 1050–1100°C under high mechanical load. Their design purpose is to maximize creep rupture life, suppress grain boundary formation, and reduce phase instability in the harsh thermal gradients of turbine hot gas paths. In conjunction with optimized internal cooling passages, film cooling holes, and advanced TBC systems, second-generation single crystal alloys enable higher turbine efficiency, lower specific fuel consumption, and longer overhaul intervals in aerospace engines, industrial gas turbines, and nuclear-related high-temperature components.

Chemical Composition

Element | Nickel (Ni) | Cobalt (Co) | Chromium (Cr) | Aluminum (Al) | Tantalum (Ta) | Tungsten (W) | Molybdenum (Mo) | Rhenium (Re) | Others (Ti, Hf, etc.) |

Typical Composition (%) | Balance | 5.0–10.0 | 2.0–7.0 | 5.0–6.5 | 4.0–8.0 | 3.0–6.0 | 0.5–2.0 | 2.0–3.0 | 0.1–1.5 (each) |

Physical Properties

Property | Density | Solidus–Liquidus Range | Thermal Conductivity (RT) | Thermal Expansion | Specific Heat (RT) |

Value | ~8.5–8.9 g/cm³ | ~1290–1350°C | ~8–12 W/m·K | ~12–15 µm/m·°C | ~400–500 J/kg·K |

Mechanical Properties

Property | Tensile Strength (RT) | Yield Strength (RT) | Elongation (RT) | Typical Creep Rupture Strength | Hardness |

Value | ~900–1100 MPa | ~700–900 MPa | ~3–6% | ~150–220 MPa at 980°C / 1000 h (alloy-dependent) | ~35–45 HRC (after full heat treatment) |

Key Material Characteristics

Single crystal structure eliminates grain boundaries, greatly improving creep and fatigue resistance in hot sections.

Optimized Re, W, and Ta content delivers high-temperature strength with controlled phase stability.

Excellent compatibility with thermal barrier coatings and diffusion coatings for extended oxidation life.

Superior resistance to thermomechanical fatigue and low-cycle fatigue under severe temperature gradients.

High microstructural stability during long service exposures in power generation turbines.

Engineered for complex internal cooling features produced via precision vacuum investment casting.

Consistent orientation control (e.g., <001> direction) for predictable elastic behavior under centrifugal loading.

High hot corrosion and oxidation resistance when combined with suitable coating systems and surface engineering.

Supports higher turbine inlet temperatures, enabling improved engine efficiency and reduced CO₂ per kWh or thrust.

Balanced design minimizes casting defects and improves manufacturing yield compared with later ultra-high alloyed generations.

Manufacturability And Post Process

Single crystal casting: Directionally solidified from seed crystals in carefully controlled thermal gradients to form defect-minimized SC structures.

Vacuum investment casting: Provides clean melt conditions, low gas pickup, and accurate reproduction of intricate airfoil and platform geometries.

Crystal orientation control: Seed selection, withdrawal rate, and thermal profile are optimized to maintain <001> alignment through the blade height.

Internal cooling features: Complex core systems enable serpentine channels, impingement cavities, and film-cooling schemes for hot gas path parts.

Post process: Includes gate removal, blending, and dimensional restoration before precision machining and coating.

Superalloy CNC machining: Used for root form finishing, shroud features, and tight-tolerance attachment interfaces.

Electrical discharge machining (EDM): Creates accurate film-cooling holes and shaped holes with minimal recast control.

Superalloy deep hole drilling: Produces long cooling passages and feed holes with tight straightness and surface finish control.

Hot isostatic pressing (HIP): Consolidates internal shrinkage porosity and improves fatigue performance for critical hardware.

Heat treatment: Multi-step solution and aging treatments optimize γ/γ′ morphology for creep resistance and toughness.

Superalloy welding: Applied selectively for repair of non-critically oriented regions, followed by re-heat treatment when qualified.

Material testing and analysis: Includes non-destructive inspection, creep, fatigue, and microstructural evaluation to validate casting integrity and life prediction.

Suitable Surface Treatment And Coatings

Thermal barrier coatings (TBC): Ceramic topcoats with metallic bond coats dramatically reduce metal temperature and oxidation rate.

Aluminide and MCrAlY bond coats: Provide oxidation and hot corrosion protection, and act as TBC-compatible underlayers.

Shot peening / surface conditioning: Enhances fatigue resistance on selected regions without compromising coating adhesion.

Laser drilling and laser surface texturing: Improves cooling-hole performance and coating adherence around film-cooling exits.

Precision polishing of gas path surfaces: Reduces roughness to enhance aerodynamic efficiency and minimize deposit buildup.

Non-destructive inspection after coating: Fluorescent penetrant, X-ray, and CT scanning coupled with material testing to verify integrity.

Common Industries and Applications

Aero-engine high-pressure turbine blades, vanes, and shrouds for aerospace and aviation applications.

Hot-section stationary and rotating components in industrial gas turbines for power plants.

Critical hot gas path parts in energy and oil and gas mechanical drive turbines.

High-temperature, high-reliability components in military and defense propulsion systems.

Special turbine hardware and experimental high-efficiency engines in nuclear-related and advanced energy programs.

Prototype and pre-production airfoils using second-generation chemistries before migration to later generations.

When to Choose This Material

High turbine inlet temperature: Ideal when metal temperatures must be safely managed above ~1000–1050°C with TBCs.

Long creep life targets: Suitable for designs requiring multi-thousand-hour creep rupture life at high stress.

Critical rotating components: Well-suited for HPT blades where centrifugal loading and thermal gradients are severe.

Efficiency-driven upgrades: Enables higher firing temperatures to boost cycle efficiency in new or upgraded engines.

Balanced cost–performance: Preferred when first-generation alloys are insufficient but later generations are not economically justified.

Demanding duty cycles: Performs well in frequent start–stop or peak-load regimes in power generation assets.

Complex cooling designs: Compatible with intricate internal passages produced by advanced investment casting and core technologies.

Stringent reliability requirements: Ideal for safety-critical systems where inspection intervals and unplanned downtime must be minimized.