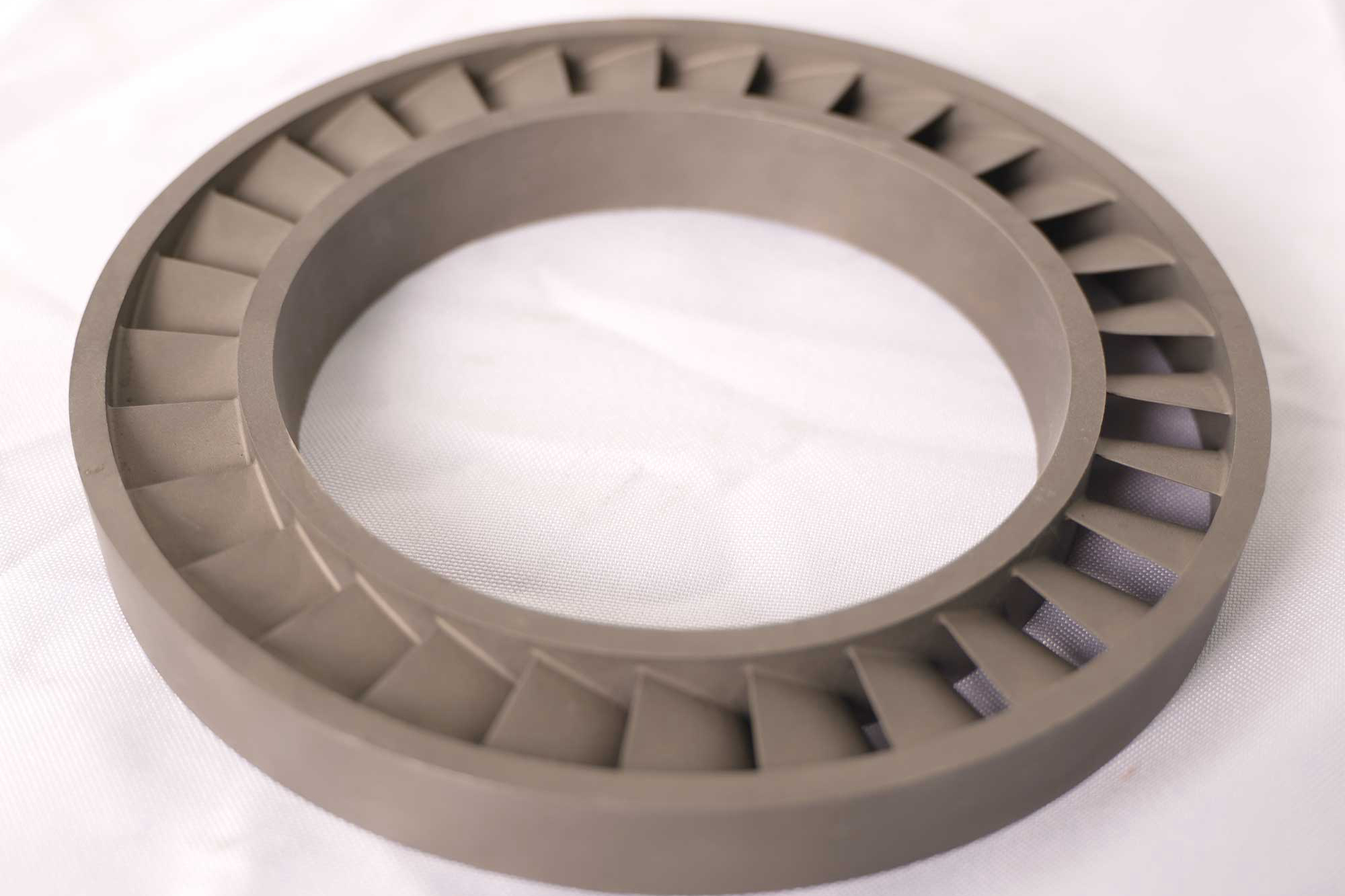

Power Generation Inconel Superalloy Parts Custom Nozzle Rings Manufacturer

Introduction to Inconel Superalloys for Nozzle Rings

Inconel superalloys are critical materials in power generation, especially for turbine nozzle rings, due to their exceptional creep resistance, superior oxidation tolerance, and reliable mechanical strength at elevated temperatures. As an experienced manufacturer, Neway AeroTech specializes in providing precision-customized nozzle rings using advanced processes such as vacuum investment casting and superalloy directional casting.

With expertise tailored specifically for the power generation industry, we deliver high-quality components engineered for peak performance, durability, and efficiency, meeting rigorous operational demands in harsh, high-temperature turbine environments.

Core Manufacturing Challenges for Inconel Nozzle Rings

Manufacturing nozzle rings from Inconel involves overcoming several significant technical challenges:

Creep Resistance: Sustaining structural integrity during prolonged exposure at temperatures up to 1000°C.

Oxidation Resistance: Ensuring reliable performance under high oxidation and corrosive environments.

Precision Casting: Achieving precise dimensional tolerances (±0.15 mm) and intricate internal cooling structures.

Machining Difficulty: Addressing Inconel’s high work-hardening rate and low thermal conductivity requires specialized machining strategies.

Detailed Inconel Nozzle Ring Manufacturing Processes

Vacuum Investment Casting

Precise wax models replicate nozzle ring geometry, capturing complex cooling channels accurately.

Ceramic molds created via refractory slurry coating; wax patterns removed by autoclave (~180°C).

Casting molten Inconel under vacuum conditions (<0.01 Pa) minimizes impurities and defects.

Controlled cooling (approximately 40°C/hour) mitigates residual stress and maintains dimensional accuracy.

Directional Casting

Controlled directional solidification aligns grain structures, enhancing creep resistance.

Optimized grain orientation achieved by precise temperature gradient control (~30–50°C/cm).

Reduced internal porosity and defects through carefully managed solidification rates (20–40°C/hour).

Comparative Overview of Inconel Manufacturing Processes

Process | Dimensional Accuracy | Surface Finish | Production Efficiency | Complexity Capability |

|---|---|---|---|---|

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | Moderate | High |

Directional Casting | ±0.20 mm | Ra 6.3–12.5 µm | Moderate | Moderate |

CNC Machining | ±0.01 mm | Ra 0.8–3.2 µm | Moderate | Moderate |

SLM 3D Printing | ±0.05 mm | Ra 6.3–12.5 µm | High | Very High |

Strategic Selection of Manufacturing Processes for Nozzle Rings

Vacuum Investment Casting: Ideal for complex internal geometries, achieving precise tolerances (±0.15 mm), suitable for medium-scale production.

Directional Casting: Optimal for turbine nozzle rings requiring enhanced creep performance with grain-aligned microstructures and ±0.20 mm accuracy.

CNC Machining: Best for final precision finishing, achieving superior accuracy (±0.01 mm) and excellent surface finishes for critical sealing surfaces.

SLM 3D Printing: Suitable for rapid prototyping or intricate cooling passages with dimensional precision (±0.05 mm).

Material Analysis Matrix for Inconel Nozzle Rings

Material | Tensile Strength (MPa) | Yield Strength (MPa) | Max Service Temp (°C) | Oxidation Resistance | Typical Application |

|---|---|---|---|---|---|

1375 | 1100 | 700 | Excellent | Compressor and turbine nozzle rings | |

1200 | 980 | 950 | Outstanding | High-temperature nozzle segments | |

880 | 460 | 815 | Exceptional | Combustion chamber liners | |

950 | 760 | 980 | Superior | High-performance turbine blades | |

1250 | 1050 | 1050 | Exceptional | Gas turbine nozzle vanes | |

1100 | 780 | 700 | Excellent | Turbine sealing rings |

Optimal Material Selection for Nozzle Rings

Inconel 718: Chosen for superior tensile strength (1375 MPa) and good oxidation resistance, ideal for turbine nozzle rings below 700°C.

Inconel 738: Recommended for nozzle segments operating at elevated temperatures (up to 950°C), due to outstanding creep strength.

Inconel 625: Preferred for combustion liners requiring high corrosion resistance and service temperatures up to 815°C.

Inconel 713C: Optimal for turbine blades and nozzle rings, offering superior creep resistance at temperatures up to 980°C.

Inconel 792: Ideal for advanced gas turbine vanes due to its exceptional oxidation resistance at peak temperatures (1050°C).

Inconel X-750: Suitable for turbine sealing rings requiring strength and fatigue resistance at moderate temperatures (~700°C).

Essential Post-processing Technologies for Inconel Nozzle Rings

Hot Isostatic Pressing (HIP): Eliminates internal porosity, enhancing component reliability under pressures of ~150 MPa and temperatures of 1200°C.

Thermal Barrier Coating (TBC): Reduces surface temperatures by ~200°C, crucial for nozzle ring performance and longevity.

Electrical Discharge Machining (EDM): Precisely fabricates complex internal cooling channels, maintaining tolerances of ±0.005 mm.

Heat Treatment: Optimizes microstructures, improving mechanical properties, oxidation resistance, and dimensional stability at high operating temperatures.

Industry Application and Case Study: Inconel 738 Nozzle Ring Manufacturing

Neway AeroTech successfully produced custom Inconel 738 turbine nozzle rings for leading power-generation turbines, employing directional casting and HIP technology to achieve exceptional creep resistance, dimensional accuracy (±0.20 mm), and oxidation protection at temperatures up to 950°C.

Our extensive expertise and stringent quality controls ensure compliance with critical power-generation industry standards, significantly enhancing operational efficiency and component longevity.

FAQs on Inconel Turbine Nozzle Ring Manufacturing

What production lead times can you offer for custom Inconel nozzle rings?

Can your facility accommodate low-volume and prototype production for turbine components?

Which power generation industry standards and certifications do your products comply with?

What post-processing methods ensure the best performance and lifespan for Inconel nozzle rings?

Do you offer technical consultation for material and process selection in nozzle ring manufacturing?