Boosting Performance of Superalloy Parts with Thermal Barrier Coatings

In the relentless pursuit of performance in sectors such as aerospace and aviation, as well as power generation, engineering boundaries are constantly being pushed. Superalloy components are the bedrock of these advancements, capable of withstanding immense mechanical loads and corrosive environments. However, their ultimate limitation is often temperature. This is where Thermal Barrier Coatings (TBCs) come into play, acting as a revolutionary "thermal shield" that allows these critical parts to operate in environments far beyond their innate melting points, thereby boosting efficiency, longevity, and reliability.

What Are Thermal Barrier Coatings (TBCs)?

At its core, a Thermal Barrier Coating is a multi-layer, advanced material system applied to the surface of superalloy components. Think of it as a high-tech insulating jacket. A typical TBC system consists of two primary layers:

Bond Coat, a metallic layer typically composed of an MCrAlY alloy (where M is Nickel, Cobalt, or a combination), is applied directly to the superalloy substrate. Its primary functions are to provide oxidation and hot corrosion resistance and to create a strong adhesive bond with the base metal.

Ceramic Topcoat: This is the true insulating layer, usually composed of Yttria-Stabilized Zirconia (YSZ). Its exceptionally low thermal conductivity is the key to creating a significant temperature drop between the hot gas path and the underlying metal component.

How TBCs Enhance Superalloy Part Performance

The application of TBCs translates into direct, measurable performance gains across several critical parameters:

Significant Substrate Temperature Reduction: A well-designed TBC system can create a temperature differential of 100-300°C (180-540°F) between the hot surface and the superalloy. This enables engines and turbines to operate at higher inlet temperatures, thereby directly increasing thermal efficiency and power output.

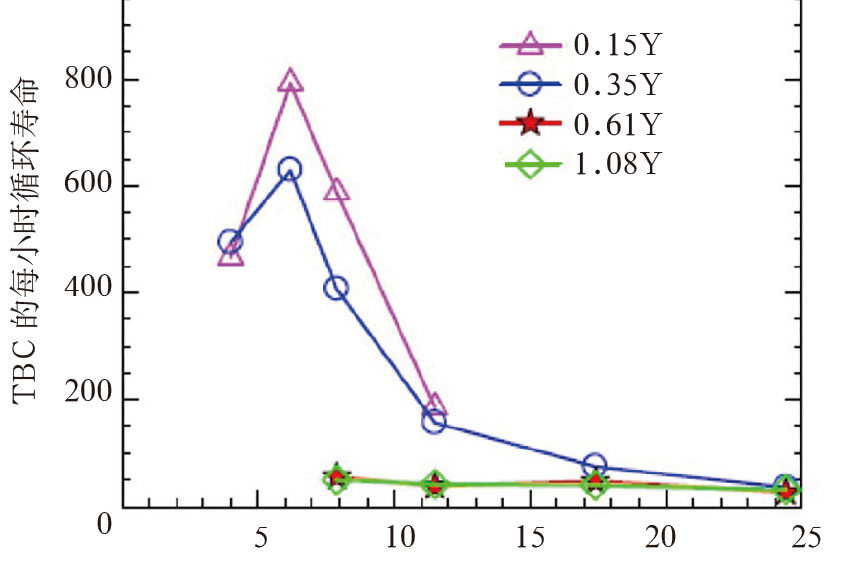

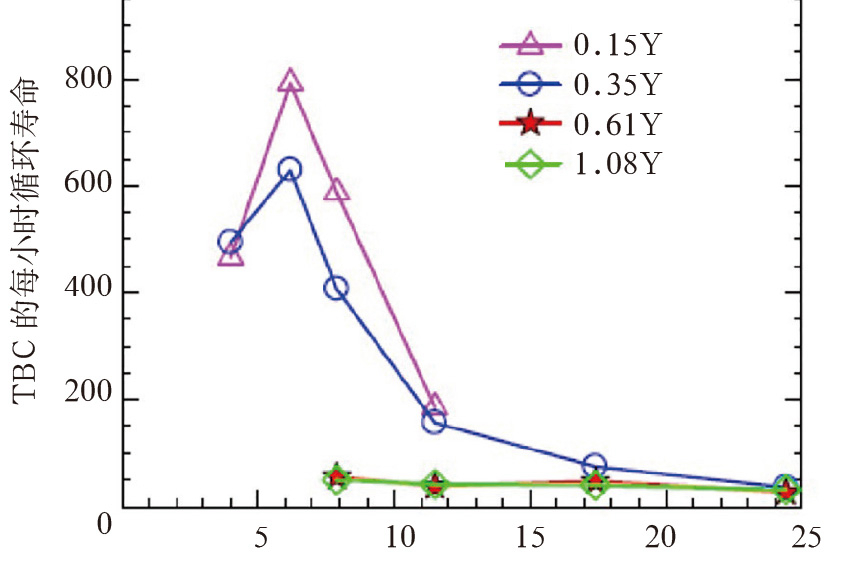

Improved Thermo-Mechanical Fatigue (TMF) Life: By shielding the metal from extreme temperature swings, TBCs drastically reduce the cyclic thermal stresses that lead to crack initiation and propagation. This is paramount for components like turbine blades that undergo constant heating and cooling cycles.

Enhanced Oxidation and Corrosion Resistance: The bond coat acts as a sacrificial layer, forming a stable, slow-growing aluminum oxide (alumina) scale (TGO - Thermally Grown Oxide) that protects the underlying superalloy from degradation.

The Manufacturing and Application Processes for TBCs

The performance of a TBC is intrinsically linked to its application method. At Neway, we employ two primary, state-of-the-art techniques:

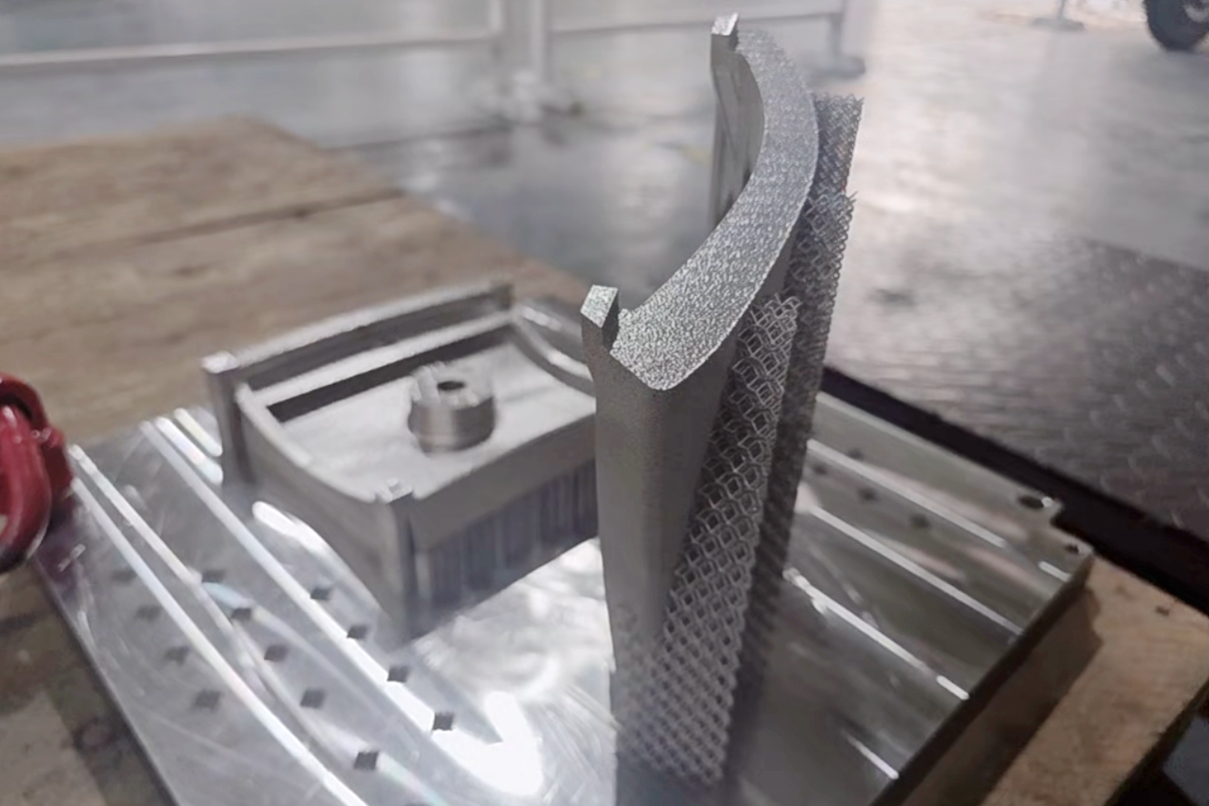

Atmospheric Plasma Spray (APS): In this process, ceramic powder is injected into a high-temperature plasma jet, where it is melted and accelerated towards the component surface. APS produces a lamellar, micro-cracked structure that offers excellent strain tolerance and is highly cost-effective for many applications.

Electron Beam Physical Vapor Deposition (EB-PVD): This advanced technique involves vaporizing the coating material in a vacuum chamber using an electron beam. The vapor then condenses on the component, building a columnar grain structure. EB-PVD coatings offer superior strain tolerance, smoother surfaces, and exceptional performance under thermal cycling, making them the preferred choice for the most demanding applications, such as single crystal turbine blades.

Superalloy Materials Compatible with TBCs

TBCs are not a standalone solution; they are part of a synergistic system with the base superalloy. Our expertise encompasses applying TBCs to a wide range of high-performance materials, including:

Nickel-Based Superalloys: These are the most common substrates for TBCs. Alloys like Inconel 718 and various Rene Alloys (e.g., Rene 80) form the backbone of high-temperature components.

Cobalt-Based Superalloys: Known for their excellent hot corrosion resistance and wear properties, alloys from the Stellite family are also prime candidates for TBC protection in specific environments.

Key Industries and Applications for TBCs

The ability to push thermal boundaries makes TBCs critical in several high-tech industries:

Aerospace and Aviation: This is the primary driver for TBC technology. They are essential on vacuum investment cast turbine blades, vanes, and combustor liners in jet engines, allowing for higher thrust-to-weight ratios and improved fuel efficiency.

Power Generation: In land-based gas turbines used for power generation, TBCs enable higher firing temperatures, leading to greater electrical output and lower emissions per megawatt generated.

Oil and Gas: Critical components in turbo-expanders and high-temperature valves within the oil and gas industry utilize TBCs to extend service life in aggressive downhole and processing environments.

Neway's Expertise in Thermal Barrier Coating Solutions

At Neway, we provide an integrated solution. Our capability extends beyond manufacturing the superalloy component; it encompasses the entire value chain. We possess advanced coating facilities equipped with both APS and EB-PVD technologies. Our rigorous material testing and analysis protocols ensure that every TBC system we deliver meets the highest standards of adhesion, microstructure, and thermal cyclic performance. Furthermore, we often integrate Hot Isostatic Pressing (HIP) and precise heat treatment processes prior to coating to ensure the substrate possesses the optimal microstructure for long-term performance.

Conclusion: Unlocking Full Potential with TBC Technology

Thermal Barrier Coatings represent a pivotal enabling technology in the world of high-temperature engineering. They are not merely an add-on but a strategic upgrade that unlocks new levels of performance and durability for superalloy parts. By partnering with a manufacturer like Neway, which offers comprehensive expertise—from advanced directional casting to state-of-the-art thermal barrier coating services—you ensure that your most critical components are built to survive and thrive in the most extreme conditions.

FAQs

What is the typical temperature reduction achieved by a Thermal Barrier Coating?

What is the expected service life of a TBC before refurbishment is needed?

Can a damaged TBC be repaired, or does the component need to be fully stripped and recoated?

What is the main difference in performance between APS and EB-PVD TBCs?

How does the choice of bond coat affect the overall performance of the TBC system?