Application of Plasma Thermal Barrier Coating in Aviation Blades

Introduction

Modern aviation turbine blades are exposed to combustion gas temperatures exceeding 1100°C—far above the melting points of even advanced superalloys like CMSX-4, PWA 1484, and Rene N5. To ensure long-term durability, oxidation resistance, and engine efficiency, these blades are protected using Plasma-Applied Thermal Barrier Coatings (TBCs). This technology enables engines to operate at higher turbine inlet temperatures (TIT), increasing thrust-to-weight ratio and reducing specific fuel consumption.

As a specialized aerospace coating provider, we apply high-performance TBCs to single-crystal and directionally solidified turbine blades, ensuring compliance with OEM coating specifications and thermal performance requirements.

Why Plasma TBC Is Critical for Aviation Blades

Aviation turbine blades experience:

Turbine inlet temperatures (TIT) above 1100°C

Thermal fatigue from repeated start-stop cycles

Oxidation and hot corrosion from combusted air-fuel mixtures

High-cycle fatigue (HCF) and creep deformation

Plasma-sprayed TBCs reduce surface temperatures by 100–200°C, protecting the substrate from oxidation and delaying the onset of creep and fatigue failure.

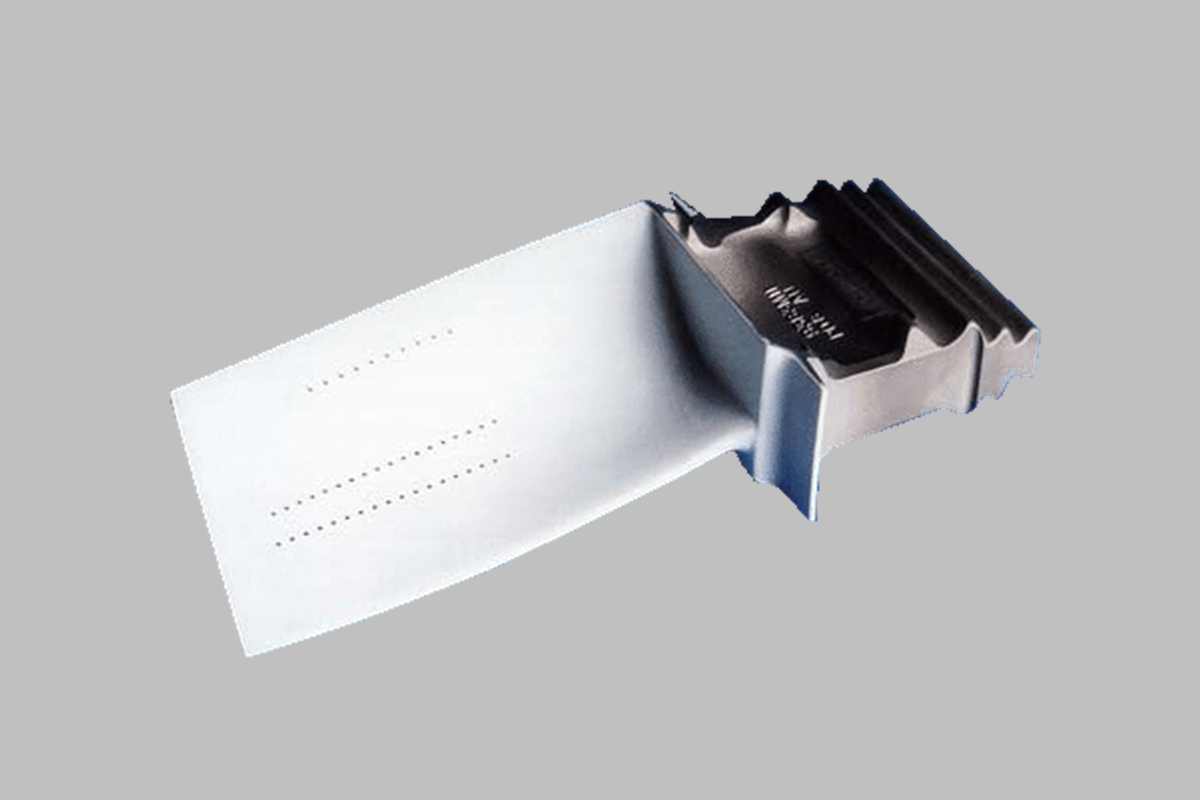

TBC System Architecture

Layer | Material | Function |

|---|---|---|

Bond Coat | NiCrAlY or PtAl (via HVOF or plasma) | Enhances adhesion and oxidation resistance |

Top Coat | 7–8 wt% Yttria-Stabilized Zirconia (YSZ) | Provides thermal insulation and strain compliance |

The total thickness typically ranges between 200–350 μm, optimized per blade geometry and OEM requirements.

Compatible Substrates for Plasma TBC

We coat a range of SX and DS superalloy aviation blades, including:

CMSX-4 – First-stage turbine blades in GE, Rolls-Royce, and Safran engines

PWA 1484 – Used in F119/F135 engines and high-performance turbofans

Rene N5/N6 – Applied in military and commercial hot-section blades

IN738LC / Rene 80 – Cast blades used in auxiliary units and early-stage turbine designs

Each substrate undergoes rigorous surface preparation, ensuring optimal adhesion and microstructural compatibility.

Plasma TBC Application Process

1. Surface Preparation

Blades are grit-blasted and cleaned to remove oxidation and contamination.

Surface roughness is controlled for bond coat adhesion.

2. Bond Coat Deposition

NiCrAlY or PtAl bond coats are applied using HVOF or low-pressure plasma spray (LPPS).

Bond coat thickness: 75–125 μm.

3. YSZ Top Coat Application

YSZ is deposited using Atmospheric Plasma Spray (APS) or Electron Beam Physical Vapor Deposition (EB-PVD).

Coating structure is optimized for strain tolerance and low thermal conductivity.

4. Post-Coating Conditioning

Heat treatment or sealing may be applied to enhance spallation resistance and match engine thermal cycling behavior.

Key Benefits of Plasma TBC for Aviation Blades

Benefit | Description |

|---|---|

Thermal Insulation | Reduces metal temperature by up to 200°C |

Creep Resistance | Delays material softening and deformation under continuous heat |

Oxidation Protection | Limits TGO growth and surface scaling during prolonged high-temperature use |

Thermal Fatigue Life | Improves resistance to cracking under cyclic heating and cooling |

Engine Efficiency | Enables higher TIT and reduces fuel consumption per thrust output |

Aerospace Coating Standards and Validation

Our coatings are applied and tested to meet engine OEM and aerospace specifications:

GE C50TF26

PWA 36945

Rolls-Royce RPS 661

ASTM C633 (Adhesion Testing)

SAE AMS 4981/4984 (Base Alloys)

Testing Includes:

Coating Thickness Measurement (±10 μm)

Thermal Shock Testing (up to 1000 cycles at 1150°C)

SEM Microstructure Analysis

TGO Growth Characterization

Adhesion Strength ≥30 MPa

Application Examples

GE9X CMSX-4 Blades: EB-PVD TBC applied for thermal cycling stability in ultra-high bypass commercial engines

F135 PWA 1484 Blades: APS TBC used to meet mission-ready requirements in stealth military jets

Trent 1000 CMSX-4 Vanes: High-adhesion ceramic coatings for improved durability in long-haul aircraft

CF6-80C2 HPT Blades (Rene N5): Thermal barrier systems enable legacy engine upgrade programs

FAQs

What’s the typical thickness of plasma-applied TBC for aviation blades?

How does APS compare with EB-PVD in terms of thermal fatigue resistance?

Can TBC be reapplied after blade refurbishment or overhaul?

What are the signs of TBC failure during engine operation?

How long can TBC-coated blades operate at 1150–1200°C?