Fifth-Generation

Material Introduction

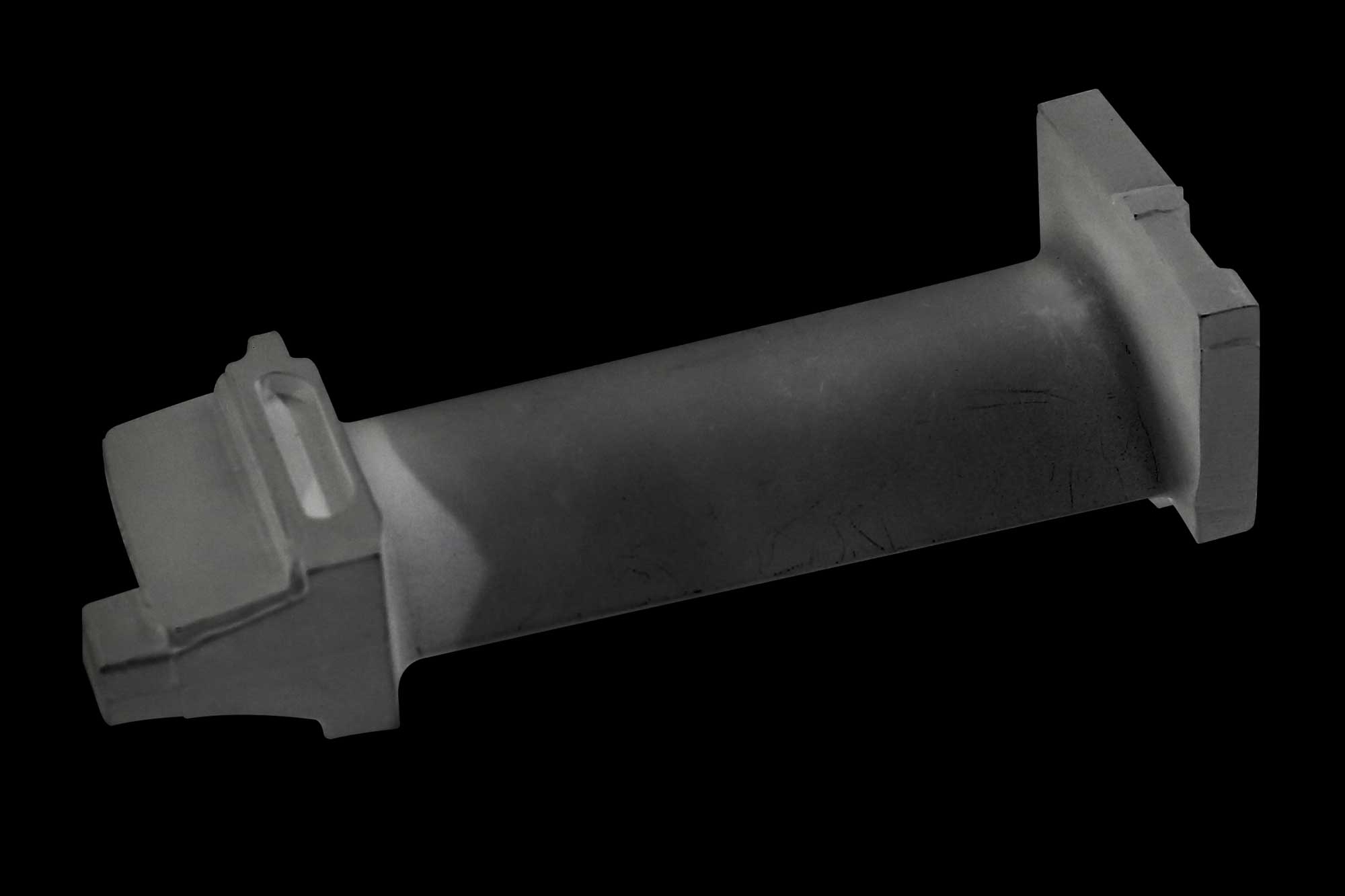

Fifth-generation single crystal superalloys represent the most advanced class of nickel-based materials currently deployed or under evaluation for ultra-high-temperature turbine applications. Developed to support even higher turbine inlet temperatures, tighter emissions targets, and extended service intervals, these alloys are produced through highly controlled fifth-generation single crystal casting routes that tightly manage crystal orientation, thermal gradients, and segregation. Chemistries typically combine elevated rhenium and ruthenium contents with optimized levels of tantalum, tungsten, and molybdenum to stabilize the γ/γ′ microstructure and suppress TCP phase formation under extreme operating conditions. Leveraging Neway AeroTech’s advanced vacuum investment casting platforms, precision core and shell technology, and rigorous process monitoring, fifth-generation single crystal components achieve exceptional structural integrity and reproducibility. When integrated with tailored heat treatment, HIP densification, and cutting-edge thermal barrier coating systems, these alloys enable unprecedented hot-section performance in next-generation aerospace engines and power generation turbines.

Alternative Material Options

While fifth-generation single crystal alloys deliver unmatched high-temperature capability, their selection must be balanced against cost, manufacturability, and fleet strategy. For high-performance engines where firing temperatures remain slightly lower, fourth-generation single crystal alloys offer a proven solution with somewhat reduced alloying complexity. Many current production platforms continue to rely on third-generation and second-generation single crystal systems where life and efficiency targets are fully met. In segments where single crystal technology is not mandatory, directional casting and equiaxed crystal casting of nickel and cobalt-based superalloys provide robust hot-section performance at lower cost. For rotating disks and heavy-section components, powder metallurgy turbine discs such as FGH96 and FGH97 remain the preferred choice. During design exploration, cooling optimization, and risk reduction, superalloy 3D printing enables rapid iteration before committing to serial production fifth-generation tooling.

International Equivalent / Comparable Grade

Country/Region | Representative Fifth-Generation / Ultra-Advanced SC Alloys | Specific Commercial / Developmental Systems | Notes |

Japan | Next-step TMS family (beyond TMS-196 / TMS-238) | Ru–Re rich alloys targeting ultra-high TIT with improved TCP resistance and coating compatibility. | |

USA | Advanced Rene and PWA concepts | Used as baselines and stepping stones for proprietary fifth-generation developments in aero engines. | |

Europe | Advanced CMSX series | CMSX-486 and higher-spec CMSX derivatives | Ru-bearing concepts targeting increased firing temperatures and extended overhaul intervals in large-frame turbines. |

China | Next-generation DD and SC series | High-performance SC alloys tailored for advanced aero and industrial gas turbines with aggressive TIT targets. | |

Global OEM Practice | Proprietary fifth-generation blends | OEM-specific variants derived from Rene, CMSX, TMS, and PWA families | Customized chemistries optimized for engine-specific duty cycles, coatings, and life management policies. |

Design Purpose

Fifth-generation single crystal superalloys were developed to enable the next leap in turbine efficiency and power density by supporting even higher firing temperatures, more aggressive cycle parameters, and extended component lives compared with previous generations. The design philosophy focuses on stabilizing the γ/γ′ microstructure against coarsening and rafting, suppressing TCP phases, and preserving coating compatibility under long-term exposure at extreme metal temperatures. Elevated ruthenium and rhenium levels, together with carefully tuned tantalum, tungsten, and molybdenum contents, allow these alloys to deliver exceptional creep rupture performance and resistance to thermomechanical fatigue. When combined with advanced internal cooling architectures and multi-layer thermal barrier coatings, fifth-generation alloys help OEMs achieve ambitious fuel-burn reductions, emission targets, and availability requirements in next-generation aerospace engines, power generation turbines, and high-end military and defense propulsion systems.

Chemical Composition

Element | Nickel (Ni) | Cobalt (Co) | Chromium (Cr) | Aluminum (Al) | Tantalum (Ta) | Tungsten (W) | Molybdenum (Mo) | Rhenium (Re) | Ruthenium (Ru) | Others (Hf, Ti, etc.) |

Typical Composition (%) | Balance | 3.0–9.0 | 1.0–4.0 | 5.0–6.5 | 4.0–8.0 | 4.0–8.0 | 0.5–3.0 | 5.0–7.0 | 3.0–5.0 | 0.1–1.5 (each) |

Physical Properties

Property | Density | Solidus–Liquidus Range | Thermal Conductivity (RT) | Thermal Expansion | Specific Heat (RT) |

Value | ~8.8–9.3 g/cm³ | ~1270–1340°C | ~7–10 W/m·K | ~12–15 µm/m·°C | ~400–500 J/kg·K |

Mechanical Properties

Property | Tensile Strength (RT) | Yield Strength (RT) | Elongation (RT) | Creep Rupture Strength | Hardness |

Value | ~950–1200 MPa | ~750–1000 MPa | ~3–6% | ~200–300 MPa at 1080–1120°C / 1000 h (alloy-dependent) | ~36–48 HRC after full heat treatment |

Key Material Characteristics

Single-crystal microstructure eliminates grain boundaries, virtually eliminating grain boundary creep and intergranular oxidation failure modes.

Ru–Re-rich chemistry provides exceptionally high-temperature creep strength and suppresses detrimental TCP phase formation.

Highly stable γ/γ′ microstructure under prolonged exposure at ultra-high metal temperatures.

Outstanding compatibility with advanced thermal barrier coating systems designed for the harshest combustion environments.

Excellent resistance to thermomechanical fatigue and severe transient loading in demanding start–stop and peak-load regimes.

Optimized for complex internal cooling architectures realized through precision vacuum investment casting and advanced core technologies.

Enables turbine inlet temperatures beyond the practical limits of second-, third-, and many fourth-generation alloys.

Compatible with HIP processing to close internal porosity and enhance fatigue performance.

Supports significant improvements in engine cycle efficiency, fuel burn, and CO₂ emissions per unit of power or thrust.

Provides a forward-looking platform for future alloy iterations and advanced engine architectures.

Manufacturability And Post Process

Fifth-generation single crystal casting: Requires extremely tight control of thermal gradients, withdrawal rates, and mold design to prevent freckles, stray grains, and recrystallization.

Vacuum investment casting: Provides high alloy cleanliness, low gas pickup, and precise reproduction of intricate airfoil and shroud geometries.

Ceramic core and shell technology: Advanced cores enable complex serpentine channels and impingement cavities, while shells are optimized for thermal stability and controlled metal–mold interaction.

Post process: Gate removal, blending, and dimensional restoration precede precision machining and coating application.

Superalloy CNC machining: Finishes root forms, fir-tree/dovetail profiles, and attachment surfaces to tight tolerances and high surface quality.

Electrical discharge machining (EDM): Produces intricate cooling holes and shaped orifices with controlled recast layers and minimal thermal damage.

Superalloy deep hole drilling: Creates long internal channels and feed passages with excellent straightness and surface finish.

Hot isostatic pressing (HIP): Consolidates shrinkage porosity and internal defects, improving low-cycle fatigue resistance and damage tolerance.

Heat treatment: Multi-step solutioning and aging cycles are carefully tuned to each fifth-generation chemistry to optimize γ/γ′ morphology and relieve residual stress.

Material testing and analysis: Comprehensive NDT, mechanical testing, and microstructural evaluation underpin life prediction models and quality assurance for safety-critical components.

Repair technologies: Qualified weld, braze, and recoating strategies can extend component life when carried out within OEM limits and followed by appropriate re-heat treatment.

Suitable Surface Treatment And Coatings

Next-generation thermal barrier coatings: Multilayer ceramic systems with highly engineered bond coats to withstand extreme gas temperatures and thermal cycling.

Advanced MCrAlY and aluminide bond coats: Tailored to Ru–Re-rich alloys for superior oxidation and hot corrosion resistance.

Overlay and diffusion coatings: Customized to handle corrosive species common in oil and gas, marine, and industrial fuels.

Laser drilling and surface texturing: Enhances cooling-hole performance and improves coating adherence around film-cooling exits.

Gas path polishing and conditioning: Reduces aerodynamic losses and manages coating stress concentrations in power generation and aerospace turbines.

Post-coating inspection and material analysis: X-ray, CT, and metallography ensure coating integrity and detect early bond coat degradation or spallation.

Common Industries and Applications

High-pressure turbine blades, vanes, and shrouds in flagship aerospace engines pursuing maximum firing temperatures and efficiency.

Next-generation power generation gas turbines targeting ultralow emissions and best-in-class combined-cycle performance.

Advanced propulsion systems in military and defense, including high-thrust, high-maneuverability platforms.

Critical mechanical drive turbines supporting demanding oil and gas and energy infrastructure with extreme duty cycles.

Demonstrator and prototype engines used to validate future turbine architectures and ultra-high temperature operating concepts.

Upgrade and life-extension projects where operators seek maximum performance gains while preserving reliability and availability.

When to Choose This Material

Ultra-extreme firing temperatures: Best suited when target turbine inlet temperatures significantly exceed the capability of fourth-generation alloys.

Maximum efficiency and fuel savings: Ideal for programs where fuel burn, emissions, and life-cycle cost are critical competitive differentiators.

Strategic, safety-critical assets: Recommended for defense propulsion and high-value power generation assets where failure risk must be minimized.

Highly loaded rotating airfoils: Especially valuable for high-pressure turbine blades subject to extreme centrifugal and thermal stresses.

Harsh operating environments: Preferred in applications with corrosive fuels or contaminants that demand robust alloy–coating synergy.

Long maintenance intervals: Supports extended service life and reduced outage frequency in both aerospace and industrial fleets.

Technology-leading platforms: Selected by OEMs developing next-generation engine architectures and seeking maximum thermal margin and reliability.

Future-proof design: Appropriate when engines are expected to see incremental firing temperature increases over their lifecycle.