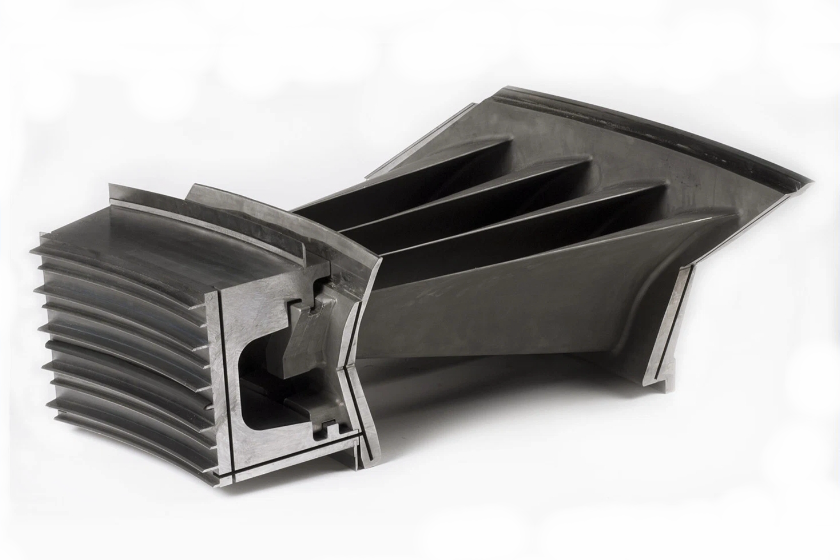

Stellite 6K Precision Casting Steam Turbine Guide Vane Manufacturer

Introduction

Stellite 6K is a cobalt-based alloy engineered for superior galling resistance, excellent erosion and corrosion resistance, and high-temperature mechanical strength. As a specialized precision casting manufacturer, we produce Stellite 6K steam turbine guide vanes with dimensional tolerances of ±0.05 mm and grain structures optimized for high-cycle fatigue resistance.

Our cast components meet the critical demands of modern steam turbine systems, offering extended service life and consistent thermal performance in severe industrial environments.

Core Technology: Precision Investment Casting of Stellite 6K

Our Stellite 6K turbine vanes are produced via precision investment casting using multi-layer ceramic shell molds (8–10 coatings), vacuum melting at ~1430°C, and mold preheating at 1000–1100°C. Controlled solidification at 40–90°C/min yields equiaxed grain sizes of 0.5–2 mm and casting porosity below 1%, ensuring superior fatigue performance and structural integrity at high operating temperatures.

Material Characteristics of Stellite 6K Alloy

Stellite 6K is a wear-resistant cobalt-chromium alloy offering excellent metallurgical stability, ideal for rotating and static components in turbines. Key properties include:

Property | Value |

|---|---|

Melting Range | 1380–1430°C |

Density | 8.45 g/cm³ |

Tensile Strength (Room Temp.) | 870 MPa |

Yield Strength | 610 MPa |

Hardness (HRC) | 38–44 HRC |

Galling Resistance | Excellent |

Thermal Stability | Up to 900°C |

Erosion/Corrosion Resistance | Excellent |

Stellite 6K’s fine carbide dispersion and balanced mechanical strength make it highly suited for precision-cast guide vanes exposed to wet steam erosion, oxidation, and sliding wear.

Case Study: Stellite 6K Steam Turbine Guide Vanes

Project Background

A thermal power station required guide vanes for a 350 MW steam turbine that operates under saturated and superheated steam flow, with frequent load cycling. Our solution: precision-cast Stellite 6K vanes conforming to ASTM F75 and utility-grade tolerances, with surface integrity and fatigue resistance tailored for long maintenance intervals.

Typical Steam Turbine Vane Applications

GE D11 Control Stage Guide Vanes: Deployed in the control stage of the GE D11 steam turbine, these vanes endure extreme inlet pressures and high-velocity steam, where erosion and impact fatigue are most critical.

Siemens SST-5000 Intermediate-Pressure (IP) Vanes: Stellite 6K vanes used in IP stages maintain excellent edge retention and shape under mid-range temperatures and fluctuating loads typical in combined cycle applications.

Doosan SKD LP Exhaust Vanes: Positioned in the low-pressure section of large base-load turbines, these vanes withstand moist, high-volume steam conditions that typically accelerate cavitation and surface erosion.

Alstom GRT Variable Guide Vanes: Ideal for retrofit or modular geometry in advanced turbine upgrades, Stellite 6K vanes in these systems provide high galling resistance under rotational adjustments in pressure-regulating stages.

These models illustrate the versatility of Stellite 6K across various OEM turbine platforms and operating stages, delivering enhanced thermal and mechanical reliability.

Guide Vane Manufacturing Solutions

Casting Process Lost wax investment casting with ceramic shell molds ensures dimensional consistency (±0.05 mm) and geometric complexity. Vacuum pouring at ~1430°C and mold preheat at ~1050°C yield refined microstructures and uniform carbide distribution across vane surfaces.

Post-processing Vanes undergo Hot Isostatic Pressing (HIP) at ~1180°C and 100 MPa to eliminate residual porosity and improve mechanical uniformity. Final machining ensures tolerances for blade roots, mounting holes, and sealing interfaces.

Surface Treatment For added durability, surfaces are optionally treated with erosion-resistant ceramic or metallic coatings. Passivation and polishing reduce surface roughness, minimizing erosion from high-velocity steam droplets.

Testing and Inspection Every vane undergoes digital X-ray inspection, CMM dimensional validation, and tensile testing at both ambient and elevated temperatures. Metallographic analysis confirms carbide distribution and grain structure.

Core Manufacturing Challenges of Steam Turbine Guide Vanes

Achieving ±0.05 mm tolerances on complex, thin-walled aerodynamic geometries.

Minimizing porosity (<1%) to ensure crack-free performance under thermal cycling.

Controlling carbide dispersion to avoid erosion hotspots and structural weakening.

Results and Verification

Stellite 6K guide vanes supplied by our foundry delivered:

Verified dimensional consistency within ±0.05 mm using 3D CMM scanning.

Surface hardness of 40–44 HRC and tensile strength ≥870 MPa.

Erosion resistance exceeding 10,000 operating hours in saturated steam environments without measurable profile degradation.

FAQs

Why is Stellite 6K preferred for steam turbine guide vane applications?

What are the advantages of precision casting over machining for vane production?

How is dimensional accuracy achieved in Stellite 6K castings?

What coatings can enhance vane erosion resistance further?

Can Stellite 6K vanes be designed for retrofit into existing turbine stages?