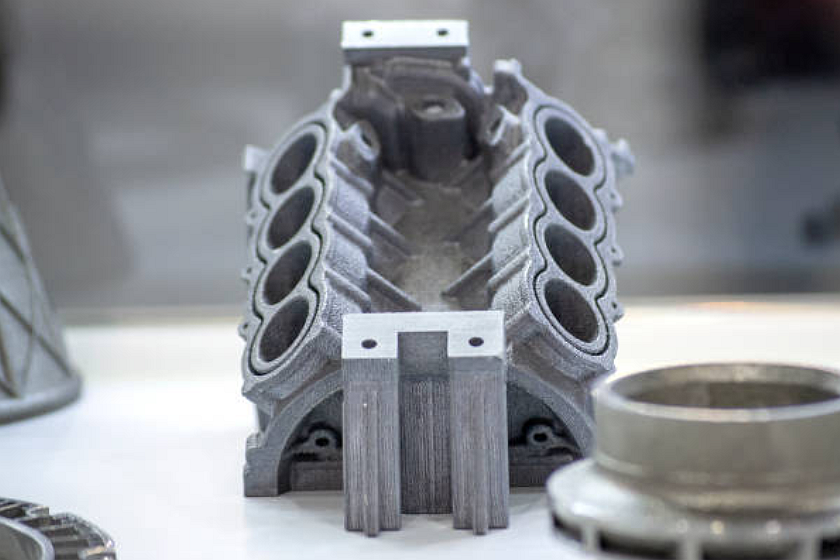

Aluminum AlSi10Mg 3D Printing Engine Parts Additive Manufacturing

Introduction to AlSi10Mg 3D Printing for Engine Components

AlSi10Mg is a high-performance aluminum alloy ideal for 3D printing engine components due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Additive manufacturing enables the production of complex, lightweight engine parts with internal cooling paths, lattice reinforcement, and high dimensional precision.

At Neway Aerotech, we offer AlSi10Mg additive manufacturing services for custom automotive and aerospace engine components requiring thermal performance, lightweight structure, and short lead times.

Overview of AlSi10Mg Additive Manufacturing

Material and Process Data

Parameter | Value |

|---|---|

Technology | |

Typical Layer Thickness | 30–50 μm |

Density (after HIP) | ≥99.5% |

Ultimate Tensile Strength | ~320 MPa (as-built), up to 460 MPa (T6) |

Elongation | 5–10% (after heat treatment) |

Thermal Conductivity | ~160 W/m·K |

Operating Temperature Limit | ~200°C (continuous) |

AlSi10Mg offers an excellent balance of stiffness, lightweight structure, and printability for engine components operating under moderate heat and load.

Why AlSi10Mg for 3D Printed Engine Parts?

Lightweight structure reduces rotational mass and inertia in engines

Superior internal cooling achievable with conformal channels and lattice structures

Rapid iteration for engine housing, manifolds, impellers, and mounts

Typical AlSi10Mg Engine Applications

Component | Functionality Description |

|---|---|

Turbo Compressor Housings | Thin-walled, internally cooled housing with integrated mounts |

Cylinder Head Prototypes | Water-cooled jackets and support ribs, pressure-tight after HIP |

Intake Manifolds | Lightweight, flow-optimized runners with integrated temperature sensors |

Oil Channel Covers | Complex fluid routing channels with low weight |

Electric Motor Mounts | Heat-dissipating structural brackets with vibration damping features |

Case Study: AlSi10Mg 3D Printed Turbo Compressor Housing

Project Background

An automotive startup required a lightweight aluminum turbo housing for a high-performance hybrid powertrain. The goal was to reduce part count and integrate flow passages, flanges, and support ribs into a single printed component.

Manufacturing Workflow

Design: Consolidated 4 parts into 1 design with optimized flow geometry and internal stiffening

Printing: SLM, 50 μm layers, build size 210 × 180 × 110 mm

Heat Treatment: T6 hardening for strength and ductility improvement

HIP: Hot Isostatic Pressing to seal micro-porosity and enhance pressure resistance

Post-Machining: Flange faces and threaded bosses finished to ±0.02 mm

Anodizing: Surface treated for corrosion protection and visual uniformity

Inspection & Validation

CMM inspection confirmed geometric tolerance within ±0.08 mm

Leak tested to 3.5 bar internal pressure—no deformation or leakage

X-ray validated HIP effectiveness with no pore clusters

Passed 100-hour dyno cycle test with zero cracks or thermal fatigue damage

Results and Performance

The 3D printed AlSi10Mg turbo housing weighed 27% less than the cast aluminum baseline and integrated three additional mounting features.

Thermal performance improved by 15% due to internal heat sink features and conformal water channels.

Tolerances and sealing integrity exceeded OEM specs for pre-series validation. Design was approved for small-series EV performance vehicle integration.

FAQs

What post-treatment is needed for AlSi10Mg printed engine parts?

Can AlSi10Mg parts be used in production or only for prototypes?

How does AlSi10Mg compare to A356 or cast 6061 in engines?

Is AlSi10Mg compatible with anodizing or coatings for corrosion protection?

What is the cost benefit of 3D printed aluminum vs CNC for engine housings?