15-5PH

Material Introduction

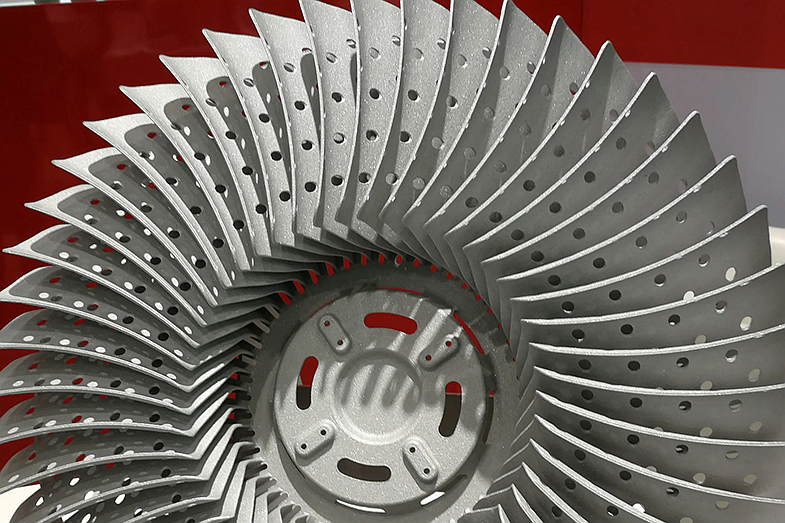

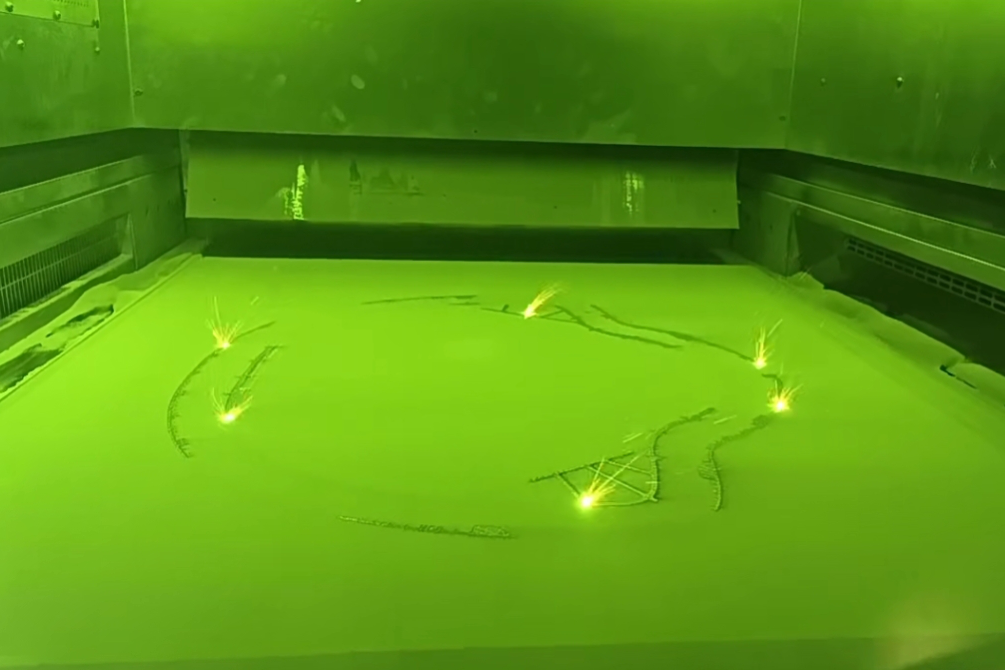

15-5PH is a precipitation-hardening martensitic stainless steel engineered to deliver high strength, excellent toughness, and strong corrosion resistance. Compared with traditional martensitic steels, 15-5PH provides improved ductility and better mechanical consistency due to its refined microstructure. In additive manufacturing, the alloy demonstrates exceptional printability, low distortion, and stable phase transformation behavior, making it suitable for high-performance applications across aerospace, energy, medical, and industrial equipment sectors. Through Neway AeroTech’s advanced 15-5PH 3D printing, components can be produced with near-full density, exhibiting excellent tensile properties and a reliable precipitation-hardening response. The alloy’s balance of strength, fatigue resistance, and corrosion performance makes it an ideal solution for complex geometries, functional prototypes, and production-grade end-use components.

International Names or Representative Grades

Region | Common Name | Representative Grades |

|---|---|---|

USA | 15-5PH Stainless Steel | UNS S15500 |

Europe | X5CrNiCu15-5 | 1.4545 |

Japan | SUS631J1 | JIS G4303 |

China | 0Cr15Ni5Cu4Nb | GB grade |

Industry Category | PH Stainless Steel | 15-5, 17-4 |

Alternative Material Options

For applications requiring higher corrosion resistance, austenitic stainless steels such as 316L provide superior resistance in marine and chemical environments. When maximum strength is required, 17-4 PH offers higher hardness and yield strength. For extreme wear resistance or tooling applications, tool steel is a more appropriate choice. When elevated-temperature performance is needed, nickel-based superalloys such as Inconel 738 deliver stronger oxidation resistance. If lightweight performance is required, titanium alloys such as Ti-6Al-2Sn-4Zr-6Mo offer excellent specific strength at a significantly lower density.

Design Purpose

15-5PH was originally developed to provide high strength, strong corrosion resistance, and improved toughness compared with earlier PH stainless steels. Its controlled chemistry minimizes delta ferrite, allowing superior ductility and better mechanical uniformity after aging treatment. In additive manufacturing, the alloy is designed to deliver stable martensitic transformation, reduced porosity, and precise dimensional accuracy. This makes it ideal for structural components, precision hardware, load-bearing assemblies, and aerospace-grade mechanical elements where reliability and accuracy are essential.

Chemical Composition (Typical Range)

Element | Composition (%) |

|---|---|

Iron (Fe) | Balance |

Chromium (Cr) | 14–15.5 |

Nickel (Ni) | 3.5–5.5 |

Copper (Cu) | 2.5–4.5 |

Niobium (Nb) | 0.15–0.45 |

Manganese (Mn) | ≤ 1 |

Silicon (Si) | ≤ 1 |

Carbon (C) | ≤ 0.07 |

Phosphorus (P) | ≤ 0.04 |

Sulfur (S) | ≤ 0.03 |

Physical Properties

Property | Value |

|---|---|

Density | ~7.75 g/cm³ |

Melting Point | 1390–1450°C |

Thermal Conductivity | ~17 W/m·K |

Electrical Resistivity | ~0.8 μΩ·m |

Specific Heat | ~500 J/kg·K |

Mechanical Properties (H900 Condition Typical)

Property | Value |

|---|---|

Tensile Strength | 1275–1310 MPa |

Yield Strength | 1170–1200 MPa |

Elongation | 8–12% |

Hardness | 38–44 HRC |

Fatigue Strength | High fatigue endurance |

Key Material Characteristics

High tensile and yield strength suitable for safety-critical components

Excellent corrosion resistance in industrial, marine, and chemical environments

Improved toughness compared with 17-4PH for applications requiring impact performance

Very low distortion during printing and post-aging heat treatment

Precipitation-hardening response ensures stable, high-strength microstructure

Strong fatigue resistance for cyclic-load components

Good weldability and dimensional stability in additive manufacturing

Fine microstructure resulting in uniform mechanical properties across printed parts

Reliable performance in both static and dynamic stress conditions

Excellent suitability for precision instruments, aerospace fittings, and mechanical hardware

Manufacturability in Different Processes

Additive manufacturing: Powder bed fusion enables the production of high-strength stainless steel components using Neway’s 15-5PH 3D printing technology.

CNC machining: Supports fine tolerances and surface finish optimization via superalloy CNC machining.

EDM processing: Complex internal geometries and high-precision features are achievable through superalloy EDM.

Deep hole drilling: Dimensional stability is maintained under precision deep hole drilling.

Heat treatment: Precipitation hardening is achieved through controlled aging using superalloy heat treatment.

Welding: Weldable with controlled parameters supported by superalloy welding.

Casting: Certain applications utilize stainless steel forming through stainless steel processing.

Suitable Post-Processing Methods

Precipitation-hardening aging treatments to achieve maximum strength

Hot Isostatic Pressing (HIP) via HIP processing for porosity removal and fatigue enhancement

Precision machining to achieve aerospace-grade dimensional tolerances

Surface polishing and grinding to improve corrosion resistance and wear properties

Passivation or chemical cleaning for improved stainless performance

Shot peening to increase fatigue strength

Dimensional inspection and material testing for quality assurance

EDM surface refinement for deep or intricate cavities

Common Industries and Applications

Aerospace brackets, hardware, hinge systems, and mechanical actuators

Medical devices, surgical tools, and sterilizable equipment

Industrial machinery requiring reliable corrosion-resistant components

Marine environment gear, shafts, and load-bearing parts

Energy sector valves, pumps, and high-strength precision hardware

Automotive performance components and drivetrain elements

When to Choose This Material

When high strength and improved toughness are required simultaneously

When printed, stainless steel must undergo aging treatment with minimal distortion

When corrosion resistance is important, but extreme alloying (e.g., nickel-based) is unnecessary

When fatigue-resistant components are needed for dynamic mechanical systems

When precision parts must maintain stability during long-term service

When cost-effective, high-performance stainless steel is preferred for 3D printing

When components require tight tolerance and excellent surface consistency

When aerospace or industrial applications demand long-term reliability