Stainless Steel

Material Introduction

Stainless steel is one of the most versatile and widely used materials in metal additive manufacturing. Its excellent corrosion resistance, mechanical strength, wear performance, and dimensional stability make it ideal for industrial, medical, marine, and consumer applications. In metal powder bed fusion, stainless steels such as 316L, 17-4 PH, 304, and tool steel variants achieve near-wrought density, fine microstructures, and strong mechanical performance. Stainless steel is highly weldable, supports thin-wall geometries, and enables the production of complex shapes that traditional machining cannot achieve. With Neway’s advanced stainless-steel additive manufacturing platforms, high-strength, corrosion-resistant components can be produced rapidly while maintaining excellent surface quality and dimensional accuracy.

International Naming Table

Category | Common Stainless Steel Grades |

|---|---|

Austenitic | 304, 316, 316L |

Martensitic | 410, 420 |

Precipitation-Hardening | 17-4 PH, 15-5 PH |

Duplex | 2205, 2507 |

Tool Steel Family | 1.2709 (Maraging steel) |

Alternative Material Options

Material selection may shift depending on performance priorities. When high strength and heat resistance are required, superalloys produced through superalloy 3D printing offer superior temperature capability. For lightweight structures, aluminum 3D printing provides excellent mass reduction. For applications requiring high biocompatibility and optimal strength-to-weight ratio, titanium alloys such as Ti-6Al-4V (TC4) or TA-series alloys are preferred. When wear resistance is essential, tool steels or hardened martensitic stainless equivalents may perform better than austenitic grades. Each alternative provides advantages for specific environments or load conditions.

Design Intent of Stainless Steel

Stainless steels were designed to resist corrosion by forming a stable chromium-rich oxide layer. Their development addressed the need for materials that maintain long-term durability in humid environments, saltwater, chemical exposure, and industrial settings. The blend of chromium, nickel, molybdenum, and other elements provides toughness, hardness, and oxidation resistance at a wide temperature range. In 3D printing, stainless steel is designed to provide reliable mechanical performance, high weldability, and consistent microstructures, making it suitable for intricate lattice structures, thin-walled components, or highly customized geometries. Its design intent in additive manufacturing emphasizes versatility: stainless steel can be used for functional prototypes, tooling inserts, mechanical assemblies, and even end-use medical or food-grade components requiring hygienic surfaces.

Chemical Composition (Generalized Austenitic 316L Example)

Element | wt% |

|---|---|

Cr | 16–18 |

Ni | 10–14 |

Mo | 2–3 |

Mn | ≤2 |

Si | ≤1 |

C | ≤0.03 |

P | ≤0.045 |

S | ≤0.03 |

Fe | Balance |

(Other stainless steels vary significantly depending on grade.)

Physical Properties

Property | Value |

|---|---|

Density | 7.7–8.0 g/cm³ |

Melting Range | 1370–1450 °C |

Thermal Conductivity | 14–18 W/m·K |

Electrical Resistivity | ~70 μΩ·cm |

Elastic Modulus | 190–200 GPa |

Coefficient of Thermal Expansion | 15–17×10⁻⁶ /K |

Mechanical Properties (AM + Heat Treated)

Property | Value |

|---|---|

Tensile Strength | 500–1200 MPa (grade dependent) |

Yield Strength | 300–1000 MPa |

Elongation | 20–45% |

Hardness | 150–350 HV |

Fatigue Resistance | Good |

Impact Toughness | Excellent for austenitic steels |

Material Characteristics

Stainless steel provides an excellent balance of strength, corrosion resistance, fatigue performance, and thermal stability. Austenitic stainless steels such as 316L exhibit exceptional ductility and toughness, even at cryogenic temperatures, making them suitable for medical devices, marine components, and food-processing applications. Precipitation-hardened grades, such as 17-4 PH, provide high strength and hardness after heat treatment, making them suitable for tooling inserts and mechanical components. In 3D printing, stainless steels offer fine microstructures with low porosity, enabling consistent mechanical behavior across the entire part. They support complex geometries, including internal channels, thin walls, and multi-functional structures requiring both mechanical performance and aesthetic surface quality. Stainless steel also maintains good dimensional stability during printing and post-processing, reducing distortion risks.

Manufacturing Process Performance

Stainless steel performs exceptionally well in powder bed fusion due to its stable melt-pool behavior and high weldability. Powder-bed fusion creates dense, uniform microstructures and excellent corrosion resistance. Beyond additive manufacturing, stainless steel can also be produced via vacuum investment casting for thick-walled components. Machining performance is generally good, although work hardening must be managed; precision finishing is often completed using superalloy CNC machining for high-tolerance parts. For deep passageways or tubing, deep hole drilling is effective, while EDM is widely used for creating sharp internal features or machining hardened materials. Stainless steel’s versatility makes it compatible with hybrid manufacturing and welded assemblies, supporting complex engineering requirements.

Applicable Post-processing

Stress relief heat treatment is commonly applied to stabilize microstructures and reduce internal stresses. HIP via Hot Isostatic Pressing enhances density and fatigue performance. Surface treatments, such as passivation, electropolishing, anodizing, and surface brightening, as well as machining and shot peening, enhance corrosion resistance, appearance, and tolerance control. Dimensional and material verification is often performed through material testing and analysis to ensure full compliance with industrial, medical, and food-grade requirements.

Common Applications

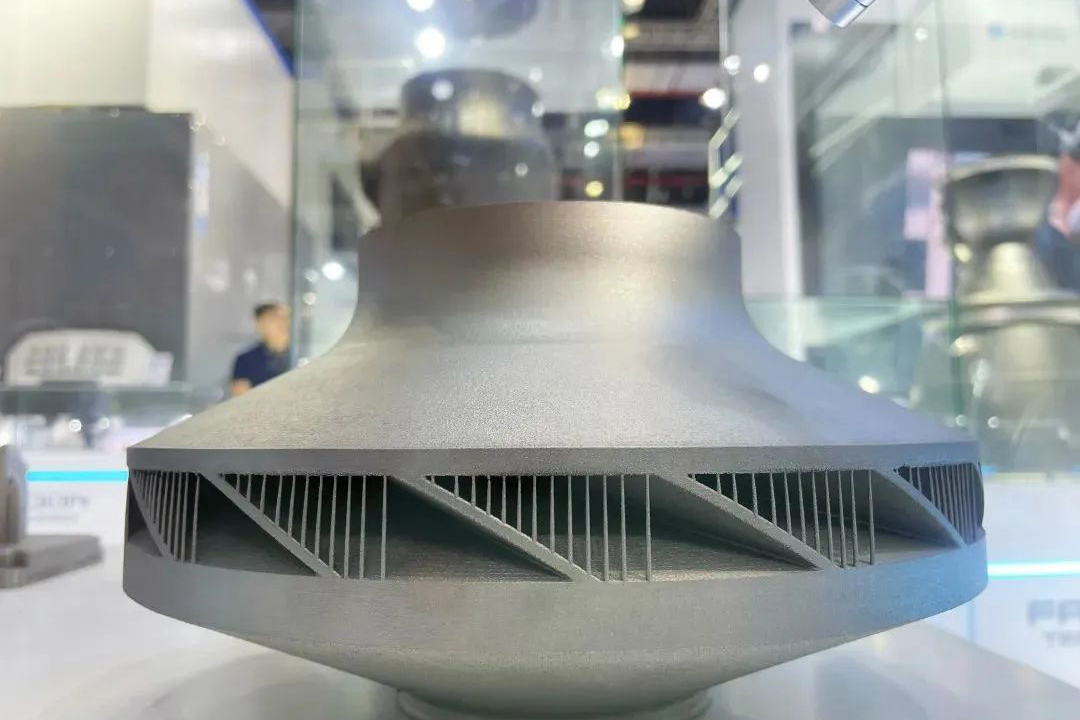

Stainless steel is widely used in mechanical assemblies, marine hardware, industrial machinery, medical surgical tools, food-processing components, pressure housings, and corrosion-resistant structures. In additive manufacturing, stainless steel enables the creation of lattice structures, custom prosthetics, specialized tools, heat exchangers, robotic joints, and durable, thin-walled housings. In energy and chemical environments, stainless steel offers superior resistance to oxidation and corrosive media, making it an ideal choice for valves, pumps, and other components used in chemical processing. Its balance of cost, durability, and manufacturability makes it one of the most universal metals for 3D printing.

When to Choose Stainless Steel

Choose stainless steel when corrosion resistance, mechanical robustness, and environmental durability are essential. It is ideal for parts requiring hygiene, structural reliability, and long-term wear performance. When fine details, complex shapes, or tight tolerances are required in functional parts, stainless steel offers excellent printability and dimensional stability. Stainless steel is also suitable for components exposed to marine environments, chemical agents, or repeated mechanical loading. It is a strong choice for tooling inserts, fixtures, food-grade components, and support structures in the automotive and aerospace industries, as well as for medical applications. However, for extremely high-temperature applications or superior lightweight performance, superalloys or titanium alloys may be better options.