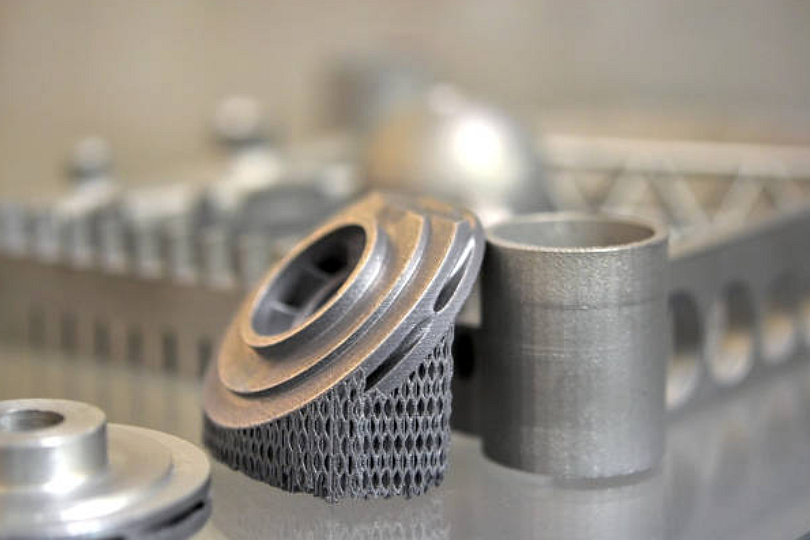

Inconel 718 3D Printing Service Superalloy Automotive Parts Supplier

Introduction to Inconel 718 3D Printing for Automotive Applications

Inconel 718 offers excellent high-temperature performance, strength, and corrosion resistance—making it an ideal material for advanced automotive components. 3D printing enables complex geometry fabrication, reduced weight, and short lead times without compromising performance under engine bay, exhaust, or turbo system conditions.

At Neway Aerotech, we provide Inconel 718 3D printing services for prototype and production-grade parts tailored to the demanding needs of the automotive industry.

Overview of Inconel 718 3D Printing Capabilities

Technical Parameters

Parameter | Value |

|---|---|

Printing Technology | |

Minimum Wall Thickness | 0.5 mm |

Layer Thickness | 40–60 μm |

As-Printed Density (after HIP) | ≥99.8% |

Tolerance | ±0.1 mm per 100 mm |

SLM-based additive manufacturing ensures structural soundness, geometric complexity, and reduced machining for Inconel 718 automotive parts.

Why Inconel 718 for Automotive Applications?

Creep resistance above 650°C for turbo and exhaust applications

Excellent fatigue strength for high-RPM rotating assemblies

Corrosion and thermal shock resistance in harsh engine bay environments

Compatible with post-processing such as EDM, HIP, and surface treatments

Common Automotive Applications

Component | Operating Temperature (°C) | Typical Wall Thickness | Description |

|---|---|---|---|

Turbocharger Exhaust Housing | 800–950 | 1.5–3 mm | Thin-wall printed geometry with integrated cooling vanes |

High-Pressure Exhaust Manifold | 700–900 | 2–4 mm | Tapered runners and flanges for twin-scroll designs |

EGR System Components | 600–750 | 1.2–2 mm | Corrosion-resistant inner ducts with complex flow paths |

Rotary Engine Combustion Seal Segments | >700 | 1 mm | Wear-resistant segments with oil-pass micro-features |

Lightweight Heat Shields | 600–750 | 0.8–1.5 mm | High-reflectivity printed shield panels with lattice backing |

Case Study: Inconel 718 3D Printed Exhaust Manifold for Performance Automotive OEM

Project Background

A performance OEM required a fully functional Inconel 718 exhaust manifold for a turbocharged inline-4 engine prototype. The part had to handle 850°C gas flow and >100,000 thermal cycles.

Manufacturing Workflow

3D Printing: SLM with 50 μm layers, build time 42 hours, print size 290 mm × 160 mm × 110 mm

HIP: Hot Isostatic Pressing at 1200°C, 100 MPa for 4 hours

CNC Machining: Mating flanges and turbo ports finished to ±0.02 mm

EDM Processing: O2 sensor port threads and exhaust merge collector polished

Surface Finishing: Grit blasting and passivation for corrosion protection

Inspection & Testing

CMM verification on all sealing surfaces

X-ray confirmed no porosity or shrinkage artifacts

Pressure tested at 5 bar; no deformation after 2000 thermal shock cycles

Visual and SEM inspection for weld-ready interfaces and structural grain continuity

Results and Performance

The Inconel 718 printed manifold showed zero cracks or warping after 300 hours of engine dyno testing at full boost.

Mounting flanges maintained flatness within 0.05 mm under high-temperature conditions.

Final part weight was reduced by 22% versus cast stainless steel while maintaining structural integrity and flow performance.

Customer approved 3D-printed manifold for vehicle integration in limited production series.

FAQs

What is the lifespan of Inconel 718 parts in high-temperature exhaust applications?

Can Inconel 718 3D printed parts replace cast or forged components directly?

What is the typical lead time for In718 3D printed automotive parts?

Are welds or sensors compatible with Inconel 718 printed manifolds?

What post-process inspections are required for high-load engine parts?