Hastelloy

Material Introduction

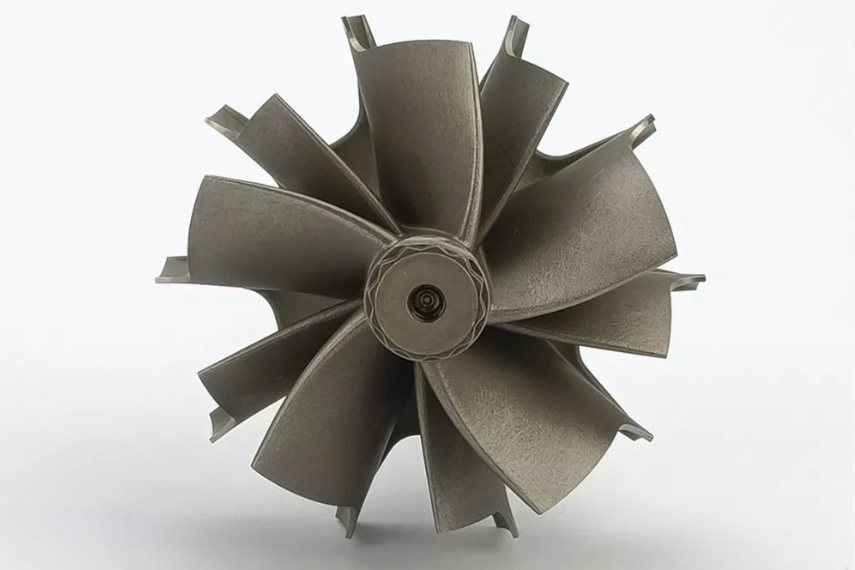

Hastelloy is a family of nickel-based, corrosion-resistant superalloys engineered for extreme environments, widely recognized for their exceptional chemical stability and high-temperature performance. In metal additive manufacturing, Hastelloy has become a preferred choice for components requiring outstanding resistance to acids, chlorides, oxidation, and thermal fatigue. When processed through advanced metal powder bed fusion technologies such as those offered by Neway AeroTech’s dedicated superalloy 3D printing, Hastelloy enables the production of intricate geometries that are difficult or impossible to achieve through conventional casting or machining. These alloys are particularly valued across chemical processing, aerospace, energy, and marine engineering, where long-term durability and structural stability are mandatory. Their robustness, weldability, and predictable metallurgy make them an ideal solution for mission-critical 3D-printed parts operating in high-risk environments.

International Names or Representative Grades

Country/Region | Common Name | Representative Grades |

|---|---|---|

USA | Hastelloy | C-22, C-276, X, B-3 |

Europe | Ni-Cr-Mo Superalloy | C-22, C-4 |

Japan | High-Corrosion Nickel Alloy | C-276 |

China | GH Series / Hastelloy | GH2761 |

Industry Classification | Corrosion-Resistant Nickel Alloy | C-22HS, G-35 |

Alternative Material Options

While Hastelloy is widely used for corrosive and high-temperature applications, several alternative materials can serve different engineering needs depending on thermal load, environmental exposure, or mechanical strength. For extreme heat applications, nickel-based alloys such as Inconel 625 and Inconel 718 offer high creep resistance, along with superior strength-to-weight performance. If oxidation resistance is prioritized, advanced cobalt-based materials, such as Stellite 6, offer excellent wear and galling resistance. For applications requiring lightweight and corrosion resistance in less aggressive environments, titanium 3D printing offers strong mechanical properties with a lower density. In situations where extreme chemical stability is critical, alloys such as Monel 400 offer a balanced alternative for marine and chemical equipment. Each option ensures a tailored approach to performance, manufacturability, and cost optimization.

Design Purpose

Hastelloy alloys were originally designed to withstand the harshest corrosive environments encountered in chemical reactors, acid processing vessels, flue-gas desulfurization systems, aerospace engine components, and high-temperature power-generation assemblies. The intentional blend of nickel, chromium, molybdenum, tungsten, and iron enables superior resistance to pitting, stress-corrosion cracking, and oxidizing or reducing media. Within additive manufacturing, the design intention expands toward enabling lighter, topology-optimized, high-strength components that retain stability under continuous thermal and chemical attack.

Chemical Composition (Typical Range: Hastelloy C-276)

Element | Composition (%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 14.5 – 16.5 |

Molybdenum (Mo) | 15 – 17 |

Iron (Fe) | 4 – 7 |

Tungsten (W) | 3 – 4.5 |

Cobalt (Co) | ≤ 2.5 |

Silicon (Si) | ≤ 0.08 |

Carbon (C) | ≤ 0.01 |

Physical Properties

Property | Value |

|---|---|

Density | ~8.9 g/cm³ |

Melting Range | 1325–1370°C |

Electrical Resistivity | ~1.25 μΩ·m |

Thermal Conductivity | ~10 W/m·K |

Specific Heat Capacity | 420 J/kg·K |

Mechanical Properties

Property | Typical Value |

|---|---|

Tensile Strength | 690–760 MPa |

Yield Strength | 280–350 MPa |

Elongation | 40–50% |

Hardness | 200–240 HB |

Fatigue Strength | High cyclic stability |

Key Material Characteristics

Exceptional corrosion resistance in reducing/oxidizing environments

Outstanding resistance to pitting, crevice corrosion, and chloride-induced attack

High stability in both acidic and alkaline media, ideal for chemical reactors

Excellent high-temperature strength for aerospace and energy systems

Superior weldability and crack resistance during additive fusion processes

Excellent metallurgical stability under cyclic thermal loading

Reliable performance in seawater and offshore environments

High resistance to stress-corrosion cracking and hydrogen embrittlement

Suitable for thin-wall and complex-geometry structures with minimal distortion

Compatible with topology-optimized lightweight designs for aerospace applications

Manufacturability in Different Processes

Additive manufacturing: Powder bed fusion enables the precise fabrication of corrosion-resistant components, supporting complex internal channels and lattice structures for aerospace, energy, and chemical equipment.

CNC machining: High work-hardening tendency requires optimized speeds, supported by Neway’s specialized superalloy CNC machining.

EDM: Excellent compatibility with superalloy EDM for hard-to-cut geometries.

Deep hole drilling: Stable under thermal stress when processed through advanced deep hole drilling methods.

Welding: High weldability when processed using controlled superalloy welding techniques.

Heat treatment: Suitable for controlled strengthening within the superalloy heat treatment workflow.

Casting compatibility: While challenging in conventional casting, modern precision techniques like vacuum investment casting are applicable for certain Hastelloy grades.

Common Post-Processing Methods

Hot Isostatic Pressing (HIP) via HIP service to eliminate porosity and enhance fatigue performance

Heat treatment for microstructure homogenization and stress relief

Surface machining for dimensional accuracy

Chemical resistance coating solutions, such as thermal barrier coating, for thermal stability

Non-destructive testing using advanced material testing and analysis

Polishing and finishing for chemical equipment requiring low surface roughness

EDM finishing for intricate internal passages

Common Industries and Applications

Aerospace engine hot-section parts, brackets, and flow components

Chemical processing reactors, pumps, valves, and piping systems

Marine and offshore equipment exposed to seawater corrosion

Energy sector applications such as heat exchangers, burners, and gas turbines

Oil and gas downhole tools, sour-gas components, and corrosion-resistant assemblies

Pharmaceutical production vessels require extreme purity and corrosion resistance

When to Choose This Material

When components will be exposed to harsh acidic or chloride environments

When the design requires both corrosion resistance and elevated-temperature performance

When long-term metallurgical stability is necessary for safety-critical systems

When weight-optimized or complex internal channels must be produced through additive manufacturing

When components are subject to both thermal cycling and aggressive chemical exposure

When weldability, crack resistance, and structural reliability are critical

When operating in seawater or marine environments, demanding high corrosion longevity

When conventional materials such as stainless steel fail due to chemical attack