Monel 401 Valve Components Equiaxed Crystal Casting Supplier

Introduction

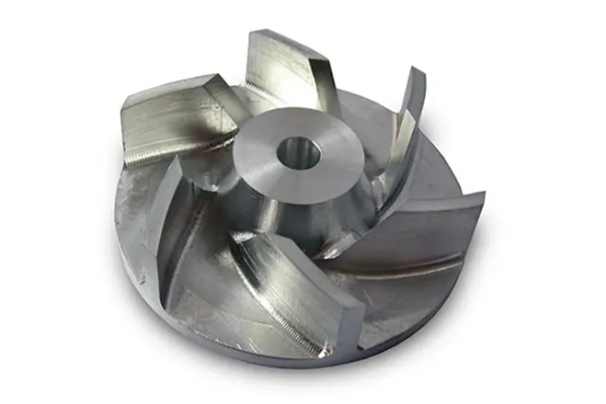

Monel 401, a nickel-copper alloy known for its outstanding mechanical properties, weldability, and resistance to corrosion and oxidation, is ideal for valve components in chemical processing, marine, and oil and gas industries. At Neway AeroTech, we utilize advanced equiaxed crystal casting techniques to produce Monel 401 valve components with excellent microstructural uniformity, precise dimensional control, and exceptional durability under harsh industrial conditions.

Our rigorous quality control ensures Monel 401 valve components offer superior performance, long operational life, and optimal reliability, meeting stringent industry standards for challenging environments involving corrosive fluids and elevated pressures.

Key Manufacturing Challenges for Monel 401 Equiaxed Casting

Controlled alloy composition to maintain uniform corrosion resistance.

Management of alloy fluidity during casting to minimize defects.

Minimizing porosity and inclusions to withstand high-pressure conditions.

Precise dimensional tolerances within ±0.05 mm for accurate component integration.

Equiaxed Crystal Casting Process for Monel 401 Valve Components

The equiaxed crystal casting process for Monel 401 valve components involves:

Wax Pattern Fabrication: Precision wax molds produced by high-accuracy injection molding.

Ceramic Shell Formation: Multiple ceramic slurry layers and fine-grained sand coatings applied and thoroughly dried.

Wax Removal (De-waxing): Steam autoclaving at approximately 150°C ensures clean wax removal without compromising shell integrity.

Vacuum Melting and Pouring: Monel 401 alloy melted under vacuum (<10⁻³ Pa) and precisely poured into ceramic molds.

Equiaxed Solidification: Controlled cooling rate (~6-8°C/min) promotes uniform, randomly oriented equiaxed grain formation.

Shell Removal and Finishing: Ceramic shell removal followed by detailed finishing, machining, and inspections.

Comparative Analysis of Valve Component Manufacturing Methods

Process | Grain Structure | Dimensional Accuracy | Corrosion Resistance | Mechanical Strength | Cost Level |

|---|---|---|---|---|---|

Equiaxed Crystal Casting | Random polycrystalline | ±0.05 mm | Excellent | Good (uniform strength) | Moderate |

Single Crystal Casting | Single crystal | ±0.03 mm | Superior | Excellent (directional) | High |

Sand Casting | Random polycrystalline | ±0.5 mm | Moderate | Moderate | Low |

CNC Machining | Machined from billet | ±0.01 mm | Good | Excellent (uniform) | High |

Valve Component Casting Process Selection Strategy

Equiaxed Crystal Casting is ideal for valve parts needing uniform properties, good strength, and cost-effective production.

Single Crystal Casting best suited for high-performance applications demanding superior directional strength and creep resistance.

Sand Casting suitable for simpler geometries with moderate precision requirements.

CNC Machining optimal for complex components needing extremely tight tolerances and exceptional surface finishes.

Monel 401 Material Performance Matrix

Material | Tensile Strength (MPa) | Max Temp (°C) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|

620 | 450 | Excellent resistance to acidic and alkaline environments | Valve components, marine fittings | |

550 | 480 | Superior marine and chemical corrosion resistance | Marine valves, chemical processing parts | |

1100 | 500 | High strength, enhanced hardness and corrosion resistance | High-pressure valve parts | |

750 | 1038 | Exceptional chemical corrosion resistance | Chemical reactors, valves | |

930 | 980 | Excellent oxidation and corrosion resistance | Turbine blades, exhaust systems | |

890 | 800 | Outstanding wear and corrosion resistance | Valve seats, stems, trims |

Rationale for Monel 401 Material Selection

Monel 401: Chosen for excellent strength and uniform corrosion resistance in acidic and alkaline valve applications.

Monel 400: Ideal for marine and general chemical environments, balancing performance and cost.

Monel K500: Selected for critical valve applications needing high strength and hardness.

Hastelloy C-276: Preferred for extreme chemical corrosion conditions.

Inconel 625: Optimal for high-temperature corrosion resistance in turbine and exhaust valves.

Stellite 6: Provides superior wear resistance for valve seats and stems.

Essential Post-processing Techniques

Hot Isostatic Pressing (HIP): Reduces microporosity at ~1150°C, 100 MPa, significantly enhancing mechanical reliability.

Precision CNC Machining: Ensures tight dimensional tolerances within ±0.01 mm, critical for assembly and function.

Thermal Barrier Coating (TBC): Enhances thermal insulation and extends service life in hot operational environments.

Material Testing & Analysis: Comprehensive metallurgical analysis ensuring consistent alloy quality and performance.

Industry Applications and Case Study

Monel 401 equiaxed cast valve components from Neway AeroTech are extensively used across chemical processing, marine, and oil & gas industries. In a notable chemical industry project involving corrosive alkali solutions, Monel 401 valve components significantly extended operational life by approximately 25% compared to conventional materials, substantially reducing downtime and maintenance costs.

FAQs

What precision can Neway AeroTech achieve with Monel 401 equiaxed cast valve components?

Why select equiaxed crystal casting for manufacturing Monel 401 valve parts?

How does Monel 401 compare to Monel 400 in valve applications?

Which industries most benefit from Monel 401 valve components?

How does Neway AeroTech ensure consistent quality and corrosion resistance in Monel 401 valve manufacturing?