为何温度管理在高温合金粗锻过程中至关重要?

目录

Thermal Stress and Deformation Control

Microstructure Stability and Grain Refinement

Process Efficiency and Post-Treatment Benefits

Quality Validation and Certification

中文 / zh

标题

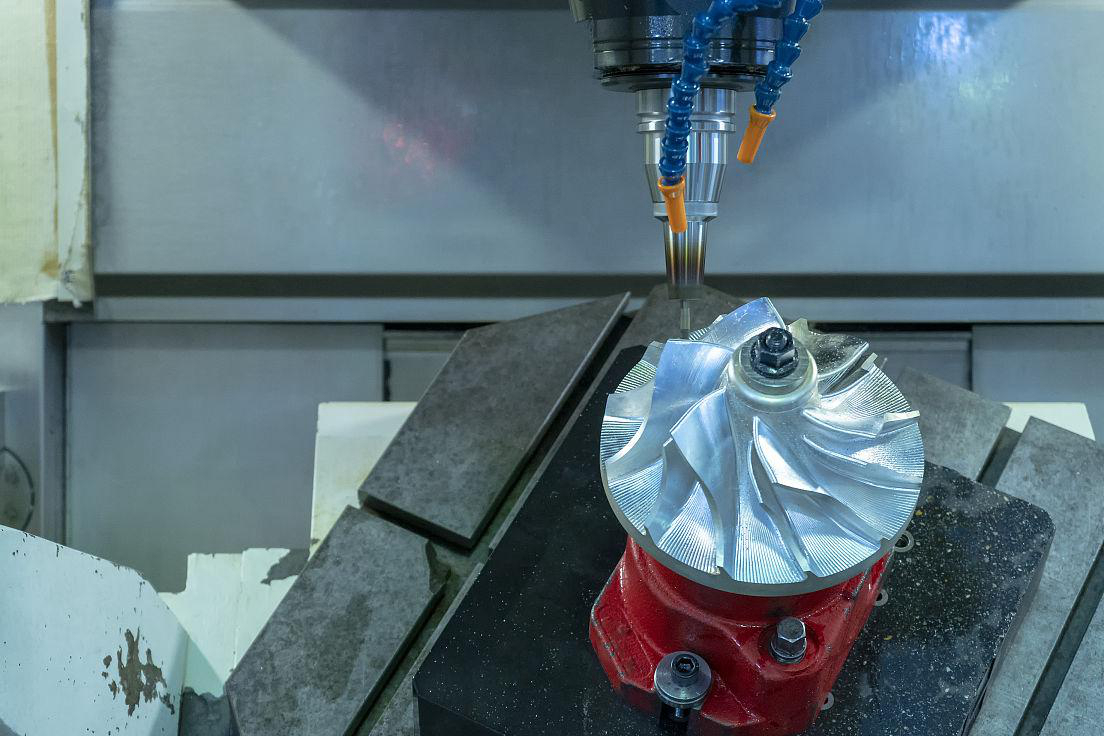

为何温度管理在高温合金粗锻过程中至关重要?

描述

粗锻过程中的温度控制可防止开裂、促进晶粒细化、支持后处理,并保持航空级高温合金的力学完整性。

关键词

粗锻温度控制,Inconel 718锻造温度,Stellite 6B塑性,晶粒细化锻造,HIP后处理准备,高温合金热管理,锻造缺陷预防,航空航天锻造标准