自由锻相比模锻具有什么关键优势?

目录

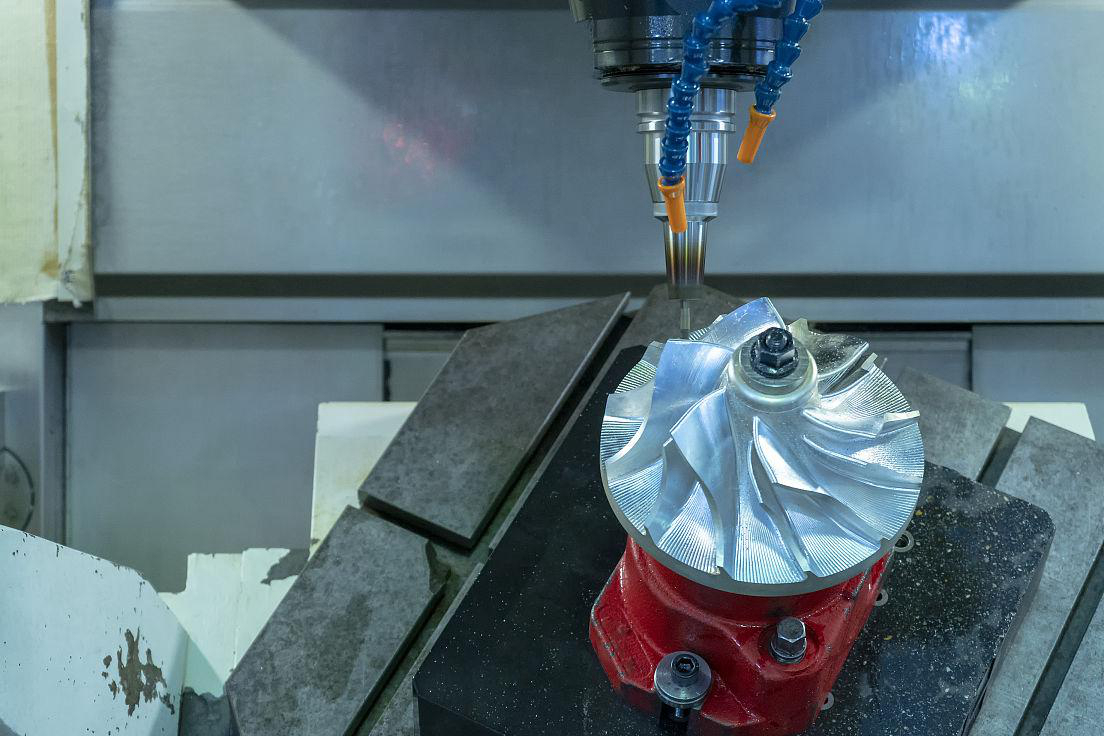

Flexibility in Production and Design

Cost Efficiency for Small-Batch Manufacturing

Material and Grain Flow Advantages

Preforming for Advanced Manufacturing

中文 / zh

标题

自由锻相比模锻具有什么关键优势?

描述

自由锻具备高灵活性、低模具成本和更佳晶粒流动性,非常适合超合金试制件与小批量生产,为后续精密成形奠定基础。

关键词

自由锻优势,开式模锻灵活性,小批量高温合金锻造,预成型粗锻,晶粒流动改善,成本高效试制,HIP准备,航空锻造方案