精密锻造如何提升屏蔽系统组件的性能?

目录

Optimized Grain Flow for Structural Integrity

Elimination of Defects and Enhanced Reliability

Superior Mechanical Properties Under Extreme Conditions

中文 / zh

标题

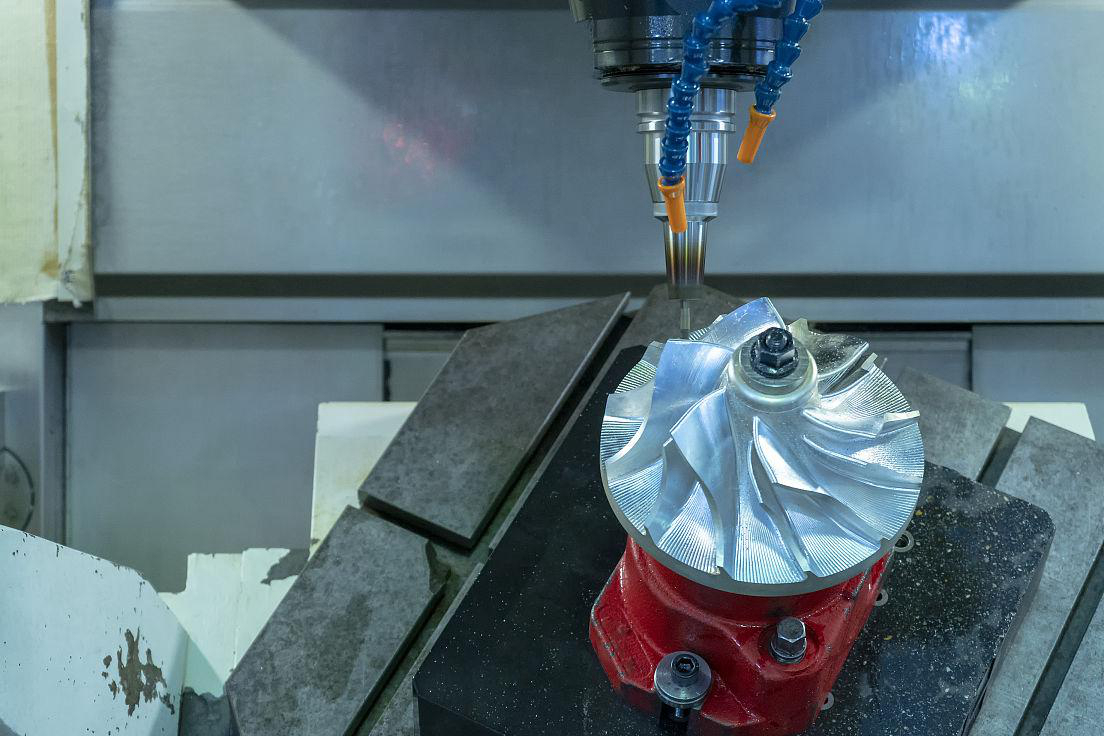

精密锻造如何提升屏蔽系统组件的性能?

描述

精密锻造通过优化晶粒流向、提高韧性并消除内部缺陷,从而显著增强屏蔽系统组件的可靠性与性能表现。

关键词

精密锻造屏蔽系统,晶粒流向结构完整性,HIP 缺陷消除,超合金锻造韧性,屏蔽环可靠性