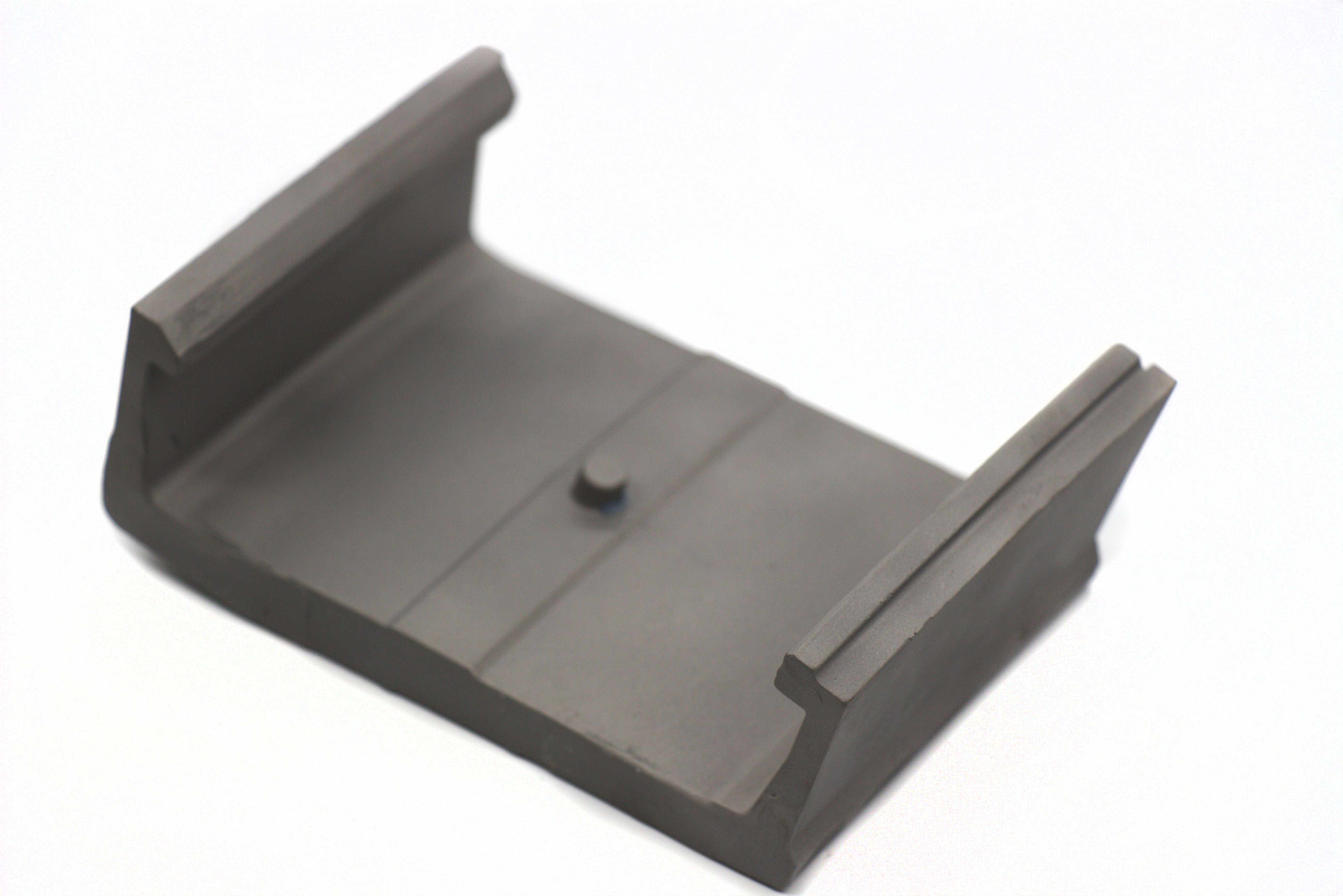

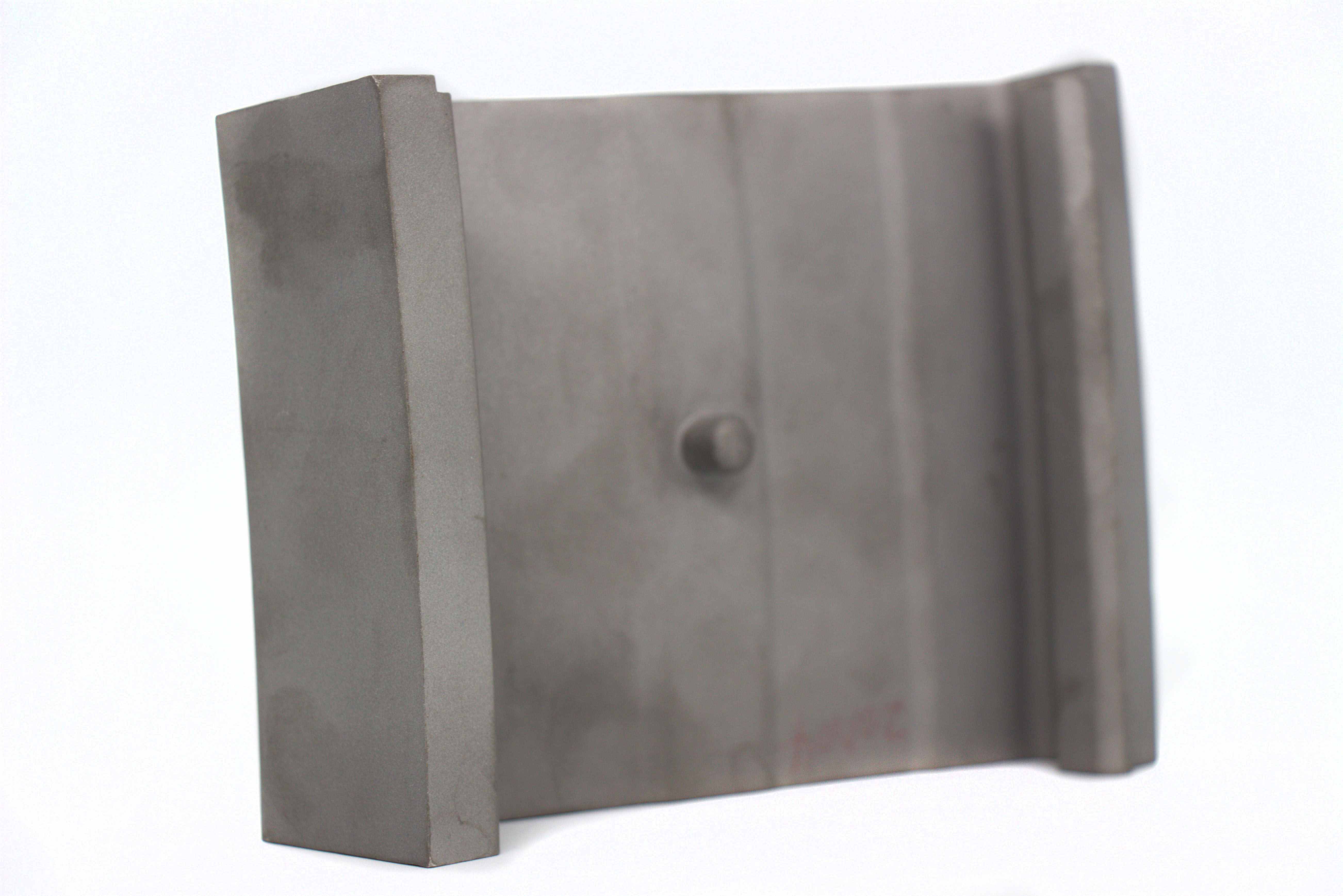

ABB: Custom Equiaxed Crystal Casting 3rd Stage Turbine Segment Manufacturing

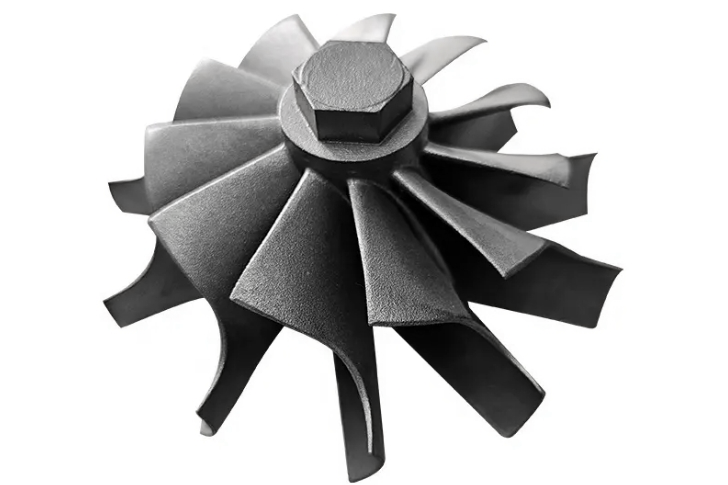

In the global shift toward cleaner and more efficient power generation, gas turbines play a crucial role in bridging renewable energy and a stable grid supply. Among the technical challenges faced by leading manufacturers like ABB, enhancing the performance of turbine hot-section components is a key priority. The third-stage turbine segment, operating under extreme temperatures and mechanical stresses, is at the heart of this evolution.

Recently, ABB initiated a strategic program to localize and optimize the manufacturing of these segments using equiaxed crystal casting technology. This approach enables a precise balance of mechanical strength, thermal fatigue resistance, and cost-effectiveness, perfectly aligned with the demanding performance requirements of next-generation combined cycle power plants.

Project Background and Requirements

The third-stage turbine segment in ABB’s latest industrial gas turbine models operates in environments exceeding 1000°C, exposed to thermal cycling, oxidation, and corrosive combustion byproducts. In addition to mechanical integrity, consistent dimensional precision and surface quality are critical for aerodynamic efficiency and long-term durability.

ABB’s technical team required a custom manufacturing solution that would deliver:

Uniform mechanical properties across segments

Controlled grain structure for optimized thermal fatigue performance

Reliable dimensional accuracy and surface finish for assembly consistency

Cost-effective production suited for both prototype and serial production volumes

Given these objectives, equiaxed crystal casting was selected as the optimal process, balancing design freedom, mechanical performance, and scalable manufacturing economics.

Material and Process Selection

Material Selection

For this project, Inconel 738 was chosen as the base alloy. This material offers a robust combination of tensile strength, creep resistance, and oxidation performance at elevated temperatures, making it ideally suited for turbine segment applications. The composition and processing history of Inconel 738 align well with equiaxed crystal casting, ensuring stable grain growth and uniform mechanical behavior.

Detailed material specifications and service capabilities of Inconel 738 can be referenced through specialized alloy solutions such as those developed for advanced casting superalloys used in vacuum investment casting.

Process Route

The selected manufacturing route is integrated.

High-precision wax pattern production

Advanced shell building with controlled permeability

Vacuum investment casting under optimized thermal gradients

Tailored cooling profiles to promote uniform equiaxed grain formation

Post-cast heat treatment to refine microstructure and optimize phase distribution

This approach leverages the flexibility of vacuum investment casting, offering both high metallurgical quality and fine feature definition. Precise control of grain size and distribution is critical in this context, as it directly influences the component's ability to resist crack initiation and propagation under thermal cycling.

Technical Challenges and Solutions

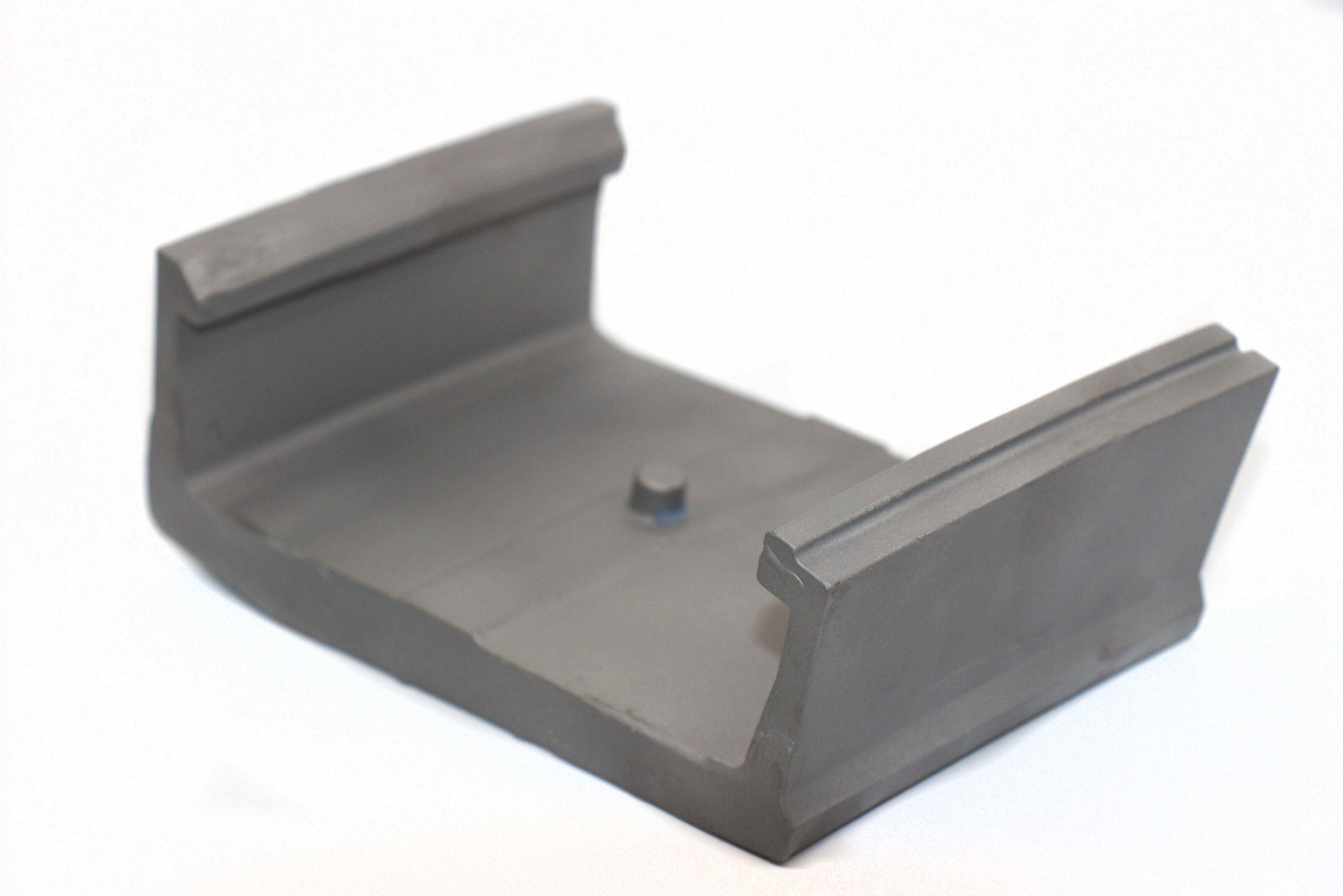

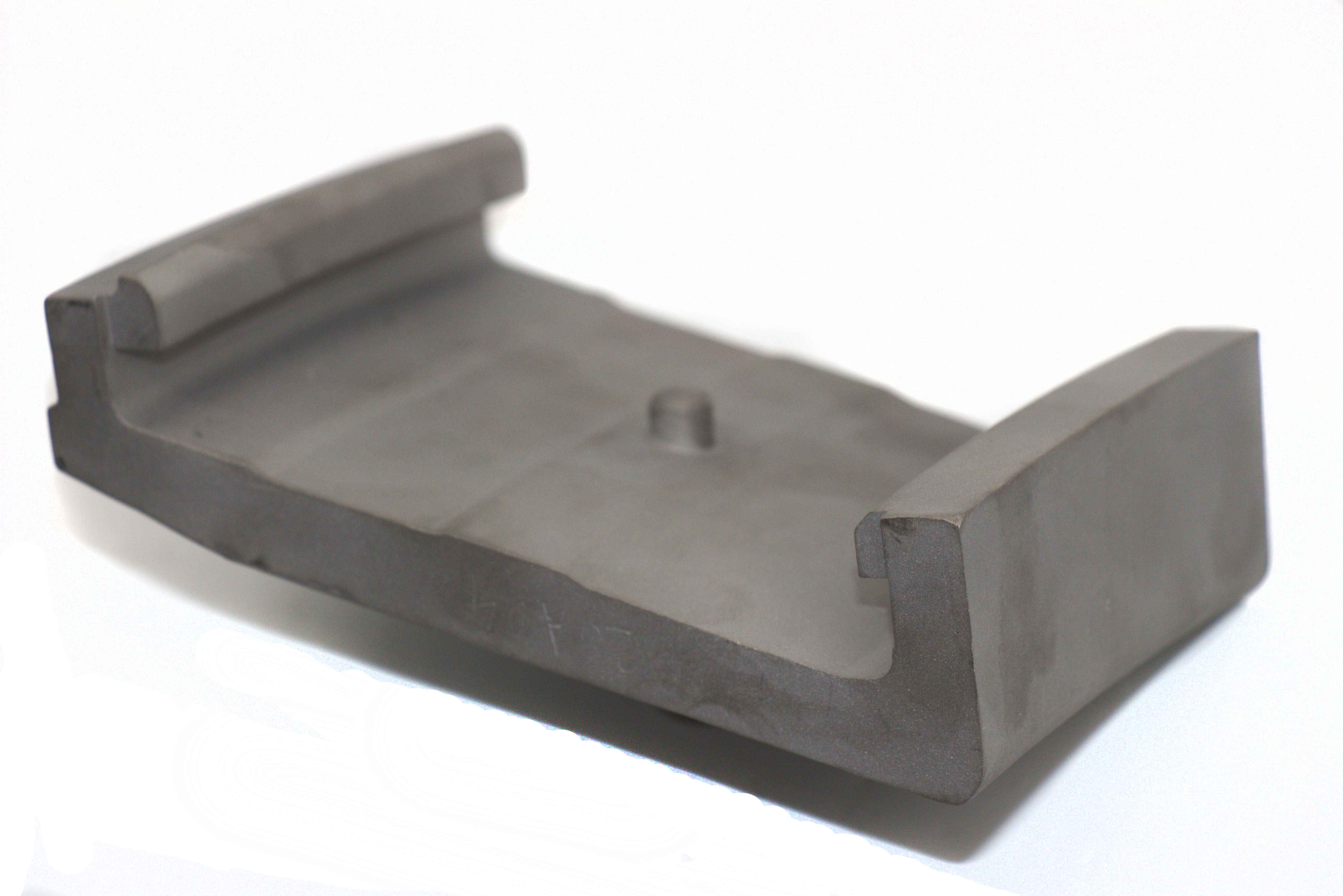

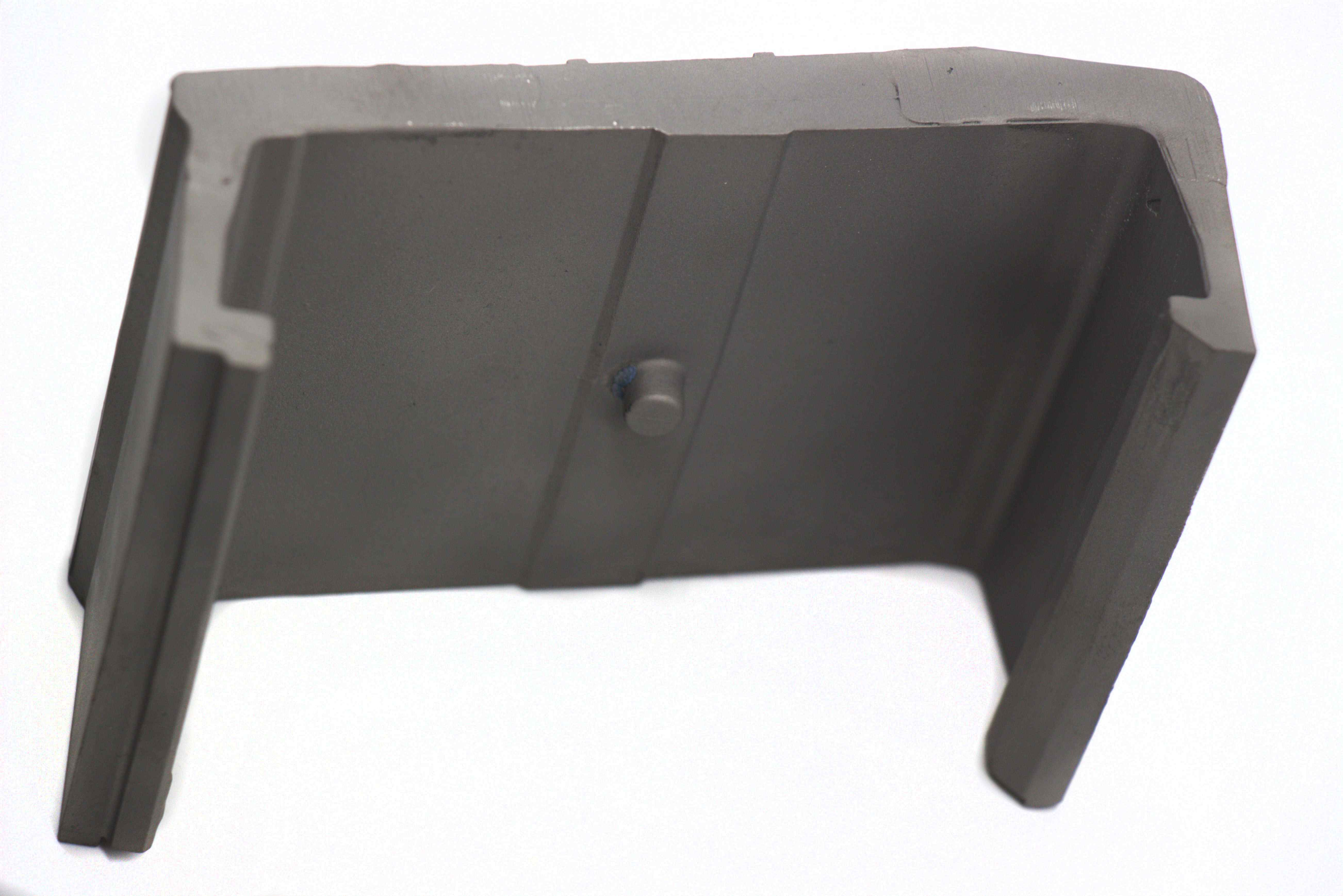

Geometric Complexity and Precision Control

The third-stage turbine segment features intricate geometries, including complex cooling passages and mounting interfaces. Achieving dimensional precision across these features required integrated digital inspection and feedback loops.

Our team utilized CMM checking and high-resolution 3D scanning to validate dimensional conformity throughout the production process. This enabled proactive adjustment of tooling and process parameters, ensuring final part geometry remained within ABB’s stringent tolerance windows.

Grain Uniformity and Defect Mitigation

Equiaxed crystal casting demands meticulous control over solidification dynamics. To minimize grain size variation and avoid unwanted segregation or porosity, our engineers fine-tuned:

Mold preheat temperatures

Pouring superheat

Controlled cooling rates within the casting chamber

In-process verification through X-ray inspection and metallographic microscopy provided a comprehensive assessment of internal quality. Any deviations were rapidly diagnosed and addressed through iterative process refinement.

Integration with Thermal Barrier Coatings

The interface between the base alloy and applied thermal barrier coating (TBC) plays a decisive role in component longevity. In this project, close collaboration between casting and coating engineers ensured that the surface chemistry and roughness profiles were fully compatible with ABB’s proprietary TBC systems, enabling durable adhesion and minimizing thermal mismatch stresses.

Preliminary Results and Quality Metrics

Initial production runs demonstrated excellent alignment with ABB’s technical specifications. Key results are summarized below:

Performance Parameter | Target Value | Actual Result | ABB Standard |

|---|---|---|---|

Grain size range (μm) | 50-150 | 60-140 | ≤150 |

Internal defects (X-ray Level) | ≤Level 2 | Level 1-2 | Level 2 |

Surface roughness Ra (μm) | ≤3.2 | 2.8-3.1 | ≤3.2 |

Tensile strength at 1000°C (MPa) | ≥850 | 870-890 | ≥850 |

Thermal fatigue cycles | ≥3000 | >3200 | ≥3000 |

Oxidation resistance (1050°C/1000h) | Pass | Pass | Pass |

These outcomes validate the robustness of the process and its suitability for full-scale implementation. ABB has expressed high satisfaction with the consistency and quality of the delivered segments.

Full-scale Production Integration

Building on the successful prototype validation phase, the project transitioned to scaled manufacturing to meet ABB’s operational demands for upcoming gas turbine models.

The process design emphasized:

Stable yield across production batches

Automated data collection for process monitoring

Robust quality assurance workflows integrating real-time inspection data

Advanced tooling and mold management practices were deployed to ensure uniform mold performance over extended production campaigns. The mold shell materials and preheat cycles were precisely controlled to maintain casting consistency. Automated tracking of thermal profiles during vacuum casting cycles further reduced process variability.

Quality Assurance and Final Verification

Each production batch underwent a comprehensive multi-stage inspection process, incorporating:

Dimensional verification using coordinate measuring machines

Non-destructive testing with X-ray inspection and ultrasonic methods

Microstructural evaluation through metallographic microscopy and scanning electron microscopy

Mechanical testing, including tensile testing at elevated temperatures

This rigorous validation framework ensured that every delivered turbine segment met ABB’s exacting standards for critical hot-section components.

In-service Performance and Customer Feedback

Following qualification, the custom-cast third-stage turbine segments were integrated into ABB’s prototype turbines for field evaluation. Real-world operational data collected from combined cycle power plants highlighted several key performance benefits:

Stable mechanical integrity under high thermal gradients

Minimal dimensional drift after extended service hours

Consistent TBC adhesion with no delamination reported

No evidence of premature cracking or oxidation-related degradation

ABB’s engineering team reported measurable gains in both thermal efficiency and component life cycle, supporting the broader goal of reducing the levelized cost of electricity (LCOE) for their advanced gas turbine platforms.

Process Innovations and Future Development

The success of this project underscored the versatility and maturity of equiaxed crystal casting as a solution for high-performance turbine components. Looking ahead, several innovation pathways are being actively explored:

Integration of hot isostatic pressing (HIP) to further enhance density and fatigue resistance

Application of AI-driven process control algorithms to optimize grain structure uniformity

Combining casting with 3D printing for the hybrid manufacturing of even more complex geometries

Collaborative development of next-generation high-temperature alloys, such as advanced Rene alloys for future gas turbine designs

Industry Context and Broader Impact

This project exemplifies how advanced manufacturing is enabling gas turbine OEMs to respond to the evolving energy landscape. In an era of volatile fuel markets and decarbonization targets, maximizing the efficiency and reliability of thermal generation assets remains a global priority.

Moreover, the localization of turbine hot-section component production, driven by partnerships with precision casting specialists, helps mitigate supply chain risks and fosters regional manufacturing ecosystems.

Through collaborative engineering efforts, ABB and its manufacturing partners are setting new benchmarks for quality and innovation in the gas turbine industry. The lessons learned here will inform the development of even more advanced solutions as the sector continues to evolve.

Conclusion

The custom manufacturing of ABB’s third-stage turbine segments through equiaxed crystal casting demonstrates how a disciplined, collaborative engineering approach can unlock significant performance gains in critical components.

By combining precise materials selection, advanced process control, and rigorous quality assurance, this project delivered components that meet and exceed the demanding service requirements of modern gas turbines.

As energy markets progress toward higher efficiency and lower emissions, such innovations in component manufacturing will remain vital to enabling the next generation of power generation technologies.

FAQs

What are the key advantages of using equiaxed crystal casting for turbine segments?

Why did ABB choose Inconel 738 for the 3rd stage turbine segment?

How does vacuum investment casting enhance component quality in turbine manufacturing?

What inspection methods are used to ensure defect-free turbine segments?

What future innovations are being explored for turbine segment manufacturing?