High-Powered 8KW Laser for Cladding Alloy Components

In the demanding world of component manufacturing and repair, the pursuit of more efficient, precise, and robust surface engineering solutions is relentless. The advent of high-powered 8KW lasers for cladding represents a significant leap forward, moving beyond the limitations of traditional methods. This advanced technology enables the application of high-performance alloy coatings with unprecedented speed, quality, and control, revolutionizing the restoration and enhancement of critical parts in industries like aerospace and power generation. At Neway, integrating this state-of-the-art capability allows us to offer superior cladding solutions that extend component life and enhance performance under extreme conditions.

What is Laser Cladding and Why Does Power Matter?

Laser cladding, also known as Laser Material Deposition (LMD), is an additive process where a high-power laser beam is used to melt a stream of metallic powder or wire as it is deposited onto a substrate. The result is a dense, metallurgically bonded coating that protects or enhances the base material. While lower-power lasers (1-4KW) are effective for fine features and thin coatings, the jump to an 8KW system unlocks new possibilities. The higher power density allows for:

Higher Deposition Rates: Significantly more material can be deposited per hour, resulting in a dramatic reduction in processing time for large components.

Deeper Dilution Control: Despite the higher power, precise parameter control ensures optimal melting of the filler material with minimal dilution into the substrate, preserving the coating's designed properties.

Ability to Clad Refractory Materials: The intense heat enables the effective processing of a wider range of high-temperature alloys that are challenging for lower-power systems.

Key Advantages of 8KW Laser Cladding Over Traditional Methods

Transitioning to high-power laser cladding from processes like Plasma Transferred Arc (PTA) welding or thermal spraying offers transformative benefits:

Minimal Heat-Affected Zone (HAZ): The concentrated laser energy inputs less total heat into the component, reducing thermal distortion and preserving the integrity of the base material, which is critical for precision forged or cast substrates.

Superior Metallurgical Bond: The process creates a fusion bond with minimal porosity and cracking, resulting in a coating that is far less likely to spall or delaminate under stress.

Enhanced Coating Quality and Performance: The fine, rapidly solidified microstructure results in improved hardness, wear resistance, and corrosion resistance compared to arc-based processes.

Process Automation and Repeatability: 8KW laser cladding is ideally suited for robotic integration, ensuring consistent, high-quality results across complex geometries and production runs.

The 8KW Laser Cladding Process: A Step-by-Step Overview

Executing a successful cladding operation with an 8KW laser involves a meticulously controlled sequence:

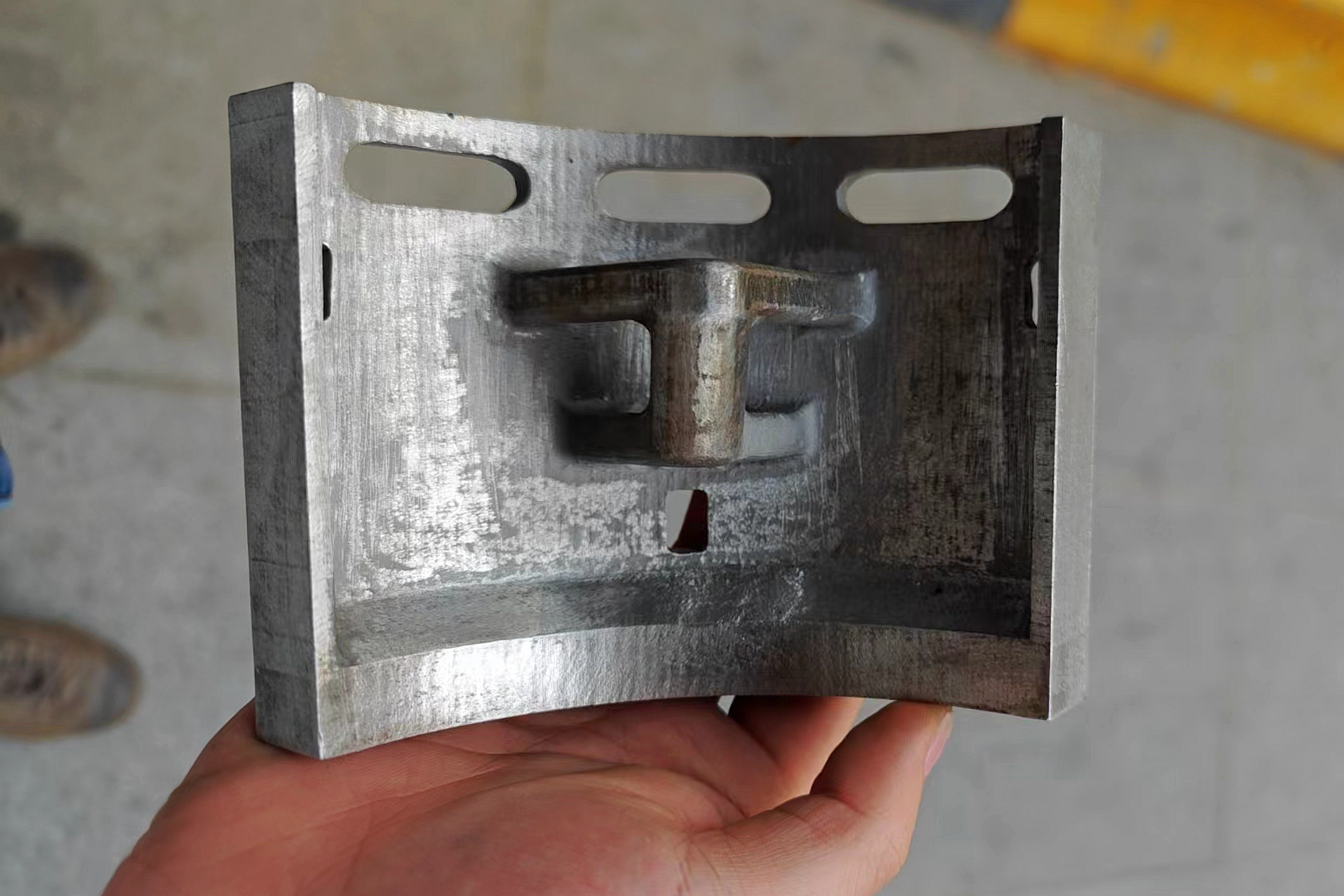

1. Substrate Preparation: The component surface is meticulously cleaned and often machined to ensure a clean, uniform base for cladding.

2. Parameter Optimization: Laser power, travel speed, powder feed rate, and spot size are calibrated based on the specific substrate and clad material combination.

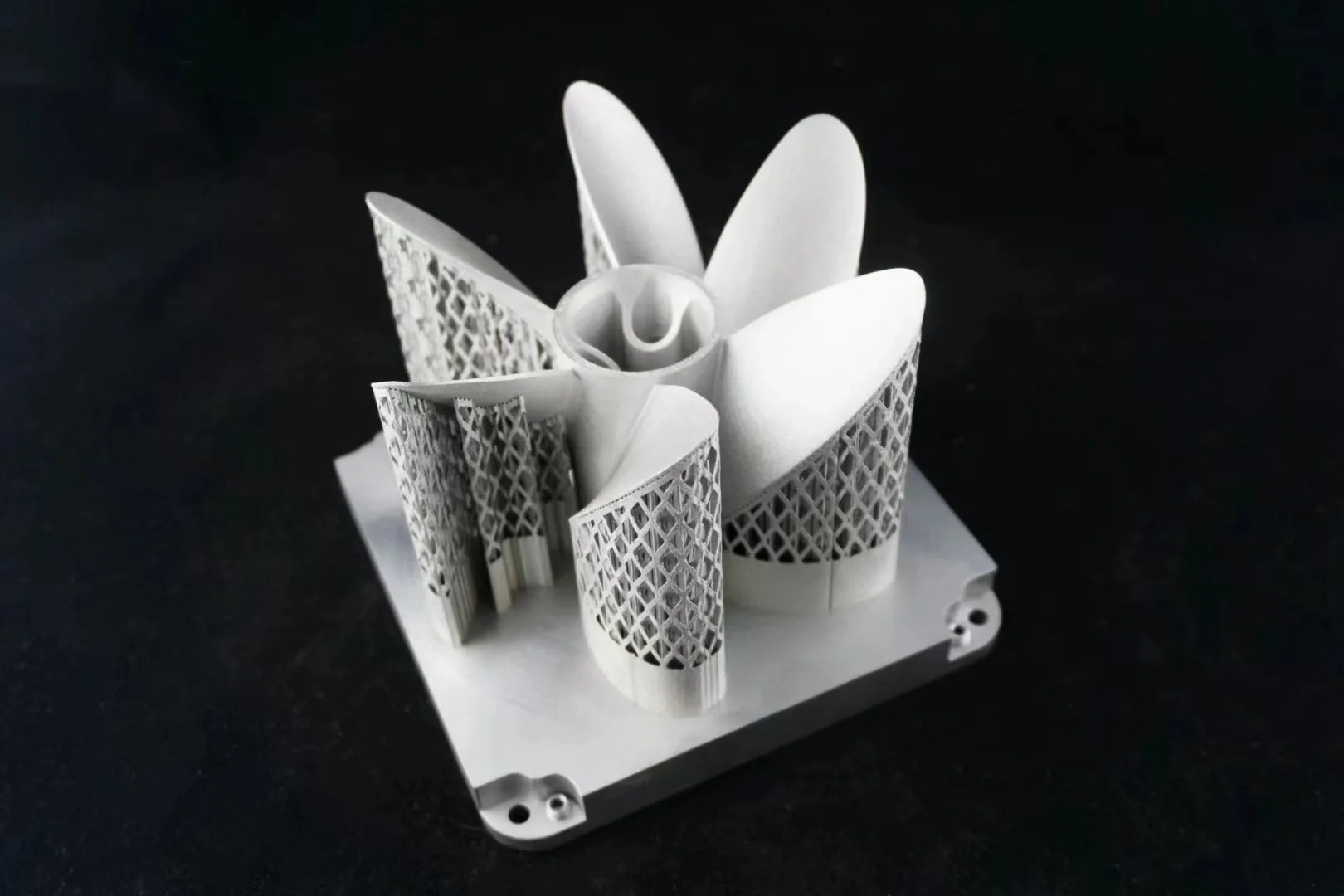

3. Cladding Operation: The robotic arm guides the laser head and powder nozzle across the target area, building up the coating layer by layer in a controlled atmosphere to prevent oxidation.

4. Post-Process Heat Treatment: To relieve residual stresses and optimize the coating microstructure, components often undergo precise heat treatment.

5. Final Machining: The clad component is finished to tight tolerances using CNC machining or deep hole drilling as required.

Ideal Materials for High-Power Laser Cladding

The 8KW laser's versatility allows us to clad a broad spectrum of advanced materials onto various substrates, including:

Cobalt-Based Alloys: Materials like Stellite 6 are exceptionally well-suited for laser cladding, providing outstanding wear and galling resistance for valve seats and hard-facing applications.

Nickel-Based Superalloys: Powders of Inconel 625 and Inconel 718 can be clad to provide high-temperature corrosion and oxidation resistance, ideal for repairing turbine blades and housings.

Stainless Steels: Grades like 316L or 17-4PH are commonly used for restoring dimensions and adding corrosion resistance to shafts and impellers.

Custom Powder Blends: We can develop tailored material compositions to meet specific application challenges, leveraging our expertise in powder metallurgy.

Critical Applications Across Industries

The combination of high power and precision makes 8KW laser clading indispensable for:

Oil & Gas: Cladding of drill string tools, wellhead components, and valve trims with corrosion-resistant alloys for extended service life in the harsh oil and gas environment.

Power Generation: Repair and protection of turbine blades, boiler components, and critical pump parts in both conventional and nuclear (nuclear) power plants.

Aerospace: Restoring worn directionally solidified turbine blades and applying wear-resistant coatings on landing gear components.

Automotive and Heavy Machinery: Rebuilding high-wear areas on engine valves, crankshafts, and hydraulic piston rods.

Neway's Integrated Approach to Advanced Cladding Solutions

At Neway, our new 8KW laser cladding system is not a standalone service; it is a core part of our integrated manufacturing and repair ecosystem. We provide a comprehensive solution:

Expert Process Development: Our engineers optimize cladding parameters for your specific material pair and application requirements.

Pre- and Post-Processing Integration: We offer full post-processing capabilities, including Hot Isostatic Pressing (HIP) to eliminate micro-porosity and precision machining to achieve final dimensions.

Quality Assurance: Every clad component undergoes rigorous material testing and analysis to ensure compliance with the highest standards for bond integrity, hardness, and dimensional accuracy.

Conclusion: Setting a New Standard with High-Power Laser Cladding

The integration of 8KW laser technology into cladding processes marks a pivotal advancement in surface engineering. It offers a powerful combination of speed, quality, and versatility that is unmatched by traditional methods. For industries where component performance, longevity, and reliability are non-negotiable, this technology provides a definitive competitive edge. By leveraging Neway's expertise in both advanced materials and state-of-the-art welding and cladding technologies, you can ensure your most critical components are protected and enhanced to withstand the extremes of modern engineering.

FAQs

Maximum coating thickness achievable with an 8KW laser cladding system

Cost comparison of 8KW laser cladding vs traditional PTA welding for large repairs

Cladding dissimilar metals like cobalt alloy onto nickel superalloy using an 8KW laser

Component size limitations for effective processing with 8KW laser cladding technology

Surface finish quality of as-clad components from an 8KW laser vs other methods