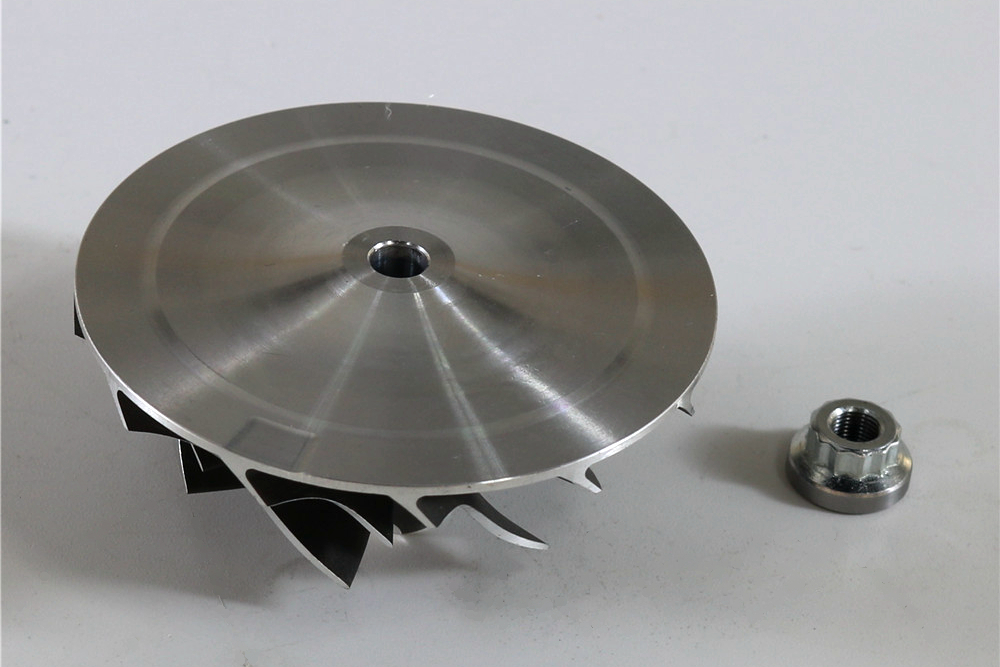

Automotive Turbocharger Wheels Inconel CNC Machining Manufacturer

Introduction to Custom Inconel Turbocharger Wheels Machining

High-performance turbochargers rely heavily on wheels capable of withstanding extreme thermal stress, corrosion, and high rotational speeds. Neway AeroTech, a specialized Inconel CNC machining manufacturer, provides precision-engineered automotive turbocharger wheels using advanced machining technologies. Utilizing robust superalloys such as Inconel 718, we deliver components exhibiting exceptional strength, durability, and thermal stability, tailored specifically for demanding automotive turbocharging applications.

Our comprehensive manufacturing expertise positions us as a trusted partner for high-performance turbocharger wheels.

Core Manufacturing Challenges in Turbocharger Wheels

Key manufacturing challenges include:

Thermal Stability: Wheels must operate effectively at temperatures exceeding 700°C without deformation.

Mechanical Strength: Components must withstand rotational speeds surpassing 150,000 RPM, requiring tensile strengths of over 1200 MPa.

Precision Machining: Achieving dimensional accuracy of ±0.005 mm and surface finishes as precise as Ra 0.8 µm.

Fatigue Resistance: Continuous high-speed operation demands superior fatigue life exceeding industry benchmarks.

Detailed CNC Machining Process for Inconel Turbocharger Wheels

CNC Turning and Milling

High-speed CNC turning achieves precise dimensions and geometric conformity.

Multi-axis CNC milling ensures complex geometries, optimized airflow paths, and weight reduction.

Employing rigid tooling and carbide inserts to handle Inconel’s high work-hardening rate and toughness.

Electrical Discharge Machining (EDM)

Wire EDM achieves intricate shapes and internal geometries impossible through conventional methods.

Precision tolerances within ±0.002 mm ensure optimal aerodynamic performance.

Reduces residual stresses typically generated by traditional machining processes.

Comparative Analysis of Manufacturing Methods

Method | Accuracy | Surface Finish | Efficiency | Complexity Handling |

|---|---|---|---|---|

CNC Turning/Milling | ±0.005 mm | Ra 0.8–1.6 µm | High | Moderate-High |

Wire EDM | ±0.002 mm | Ra 0.4–0.8 µm | Moderate | Very High |

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | Moderate | High |

Additive Manufacturing (SLM) | ±0.10 mm | Ra 6.3–12.5 µm | Moderate | Very High |

Manufacturing Process Selection Strategy

CNC Turning and Milling: Best suited for precision, high-volume turbocharger wheel production requiring stringent dimensional accuracy (±0.005 mm).

Electrical Discharge Machining (EDM): Optimal for highly intricate internal geometries demanding extremely tight tolerances (±0.002 mm).

Vacuum Investment Casting: Effective for producing complex shapes economically at moderate accuracy (±0.15 mm).

Selective Laser Melting (SLM): Ideal for prototyping and complex internal cooling channels but with moderate surface finishes (Ra ~10 µm).

Inconel Material Performance Matrix

Material | Tensile Strength | Yield Strength | Max Temp | Fatigue Life | Primary Automotive Application |

|---|---|---|---|---|---|

1240 MPa | 1030 MPa | 704°C | Superior | High-speed turbocharger wheels | |

880 MPa | 460 MPa | 980°C | Excellent | High-temperature turbine parts | |

1100 MPa | 1000 MPa | 950°C | Outstanding | Precision turbine blades | |

1300 MPa | 850 MPa | 704°C | Exceptional | High-performance rotating parts | |

1200 MPa | 950 MPa | 980°C | Superior | Turbocharger blades & wheels | |

970 MPa | 650 MPa | 650°C | Very Good | Corrosion-resistant parts |

Material Selection Criteria

Inconel 718: Chosen for wheels requiring maximum strength (1240 MPa tensile) and reliability at high RPM conditions.

Inconel 625: Selected for turbocharger components exposed to elevated temperatures (980°C) with strong corrosion resistance.

Inconel 713C: Preferred for precision turbine blades needing high strength (1100 MPa) and thermal stability (950°C).

Inconel X-750: Ideal for rotating components demanding exceptional fatigue life and mechanical integrity (1300 MPa tensile).

Inconel 738: Recommended for high-temperature turbocharger wheels requiring robust strength (1200 MPa tensile).

Inconel 925: Suitable for parts operating in corrosive environments requiring balanced strength (970 MPa tensile).

Key Post-processing Technologies

Heat Treatment: Enhances mechanical properties and fatigue life by refining the alloy microstructure.

Hot Isostatic Pressing (HIP): Removes internal porosity, improving structural integrity at temperatures (~1200°C) under pressures of 150 MPa.

Thermal Barrier Coating (TBC): Protects against extreme thermal stresses by reducing surface temperatures (~200°C lower).

Dynamic Balancing: Ensures minimal vibration, essential for high-speed rotating turbocharger wheels (>150,000 RPM).

Industry Case Study: CNC Machined Inconel Turbocharger Wheel Production

Neway AeroTech successfully manufactured precision CNC-machined Inconel 718 turbocharger wheels for a leading automotive OEM. Our advanced multi-axis CNC processes, combined with rigorous heat treatment and dynamic balancing, deliver components with exceptional strength, precise dimensional accuracy (±0.005 mm), superior fatigue life, and robust thermal stability, significantly outperforming standard industry requirements.

Our proven expertise and advanced CNC machining capabilities reinforce our position as a trusted automotive turbocharger wheel manufacturer.

FAQs

What is your standard lead time for producing CNC-machined Inconel turbocharger wheels?

Do you offer prototype or small-volume machining for automotive turbocharger components?

Which automotive industry certifications do your Inconel turbocharger wheels comply with?

Can you assist in selecting the most suitable Inconel alloys for specific turbocharger applications?

What testing methods do you use to validate the performance and reliability of your turbocharger wheels?