Ti-5Al-2.5Sn (Grade 6) Lost Wax Casting High-Performance Aircraft Components Foundry

Introduction

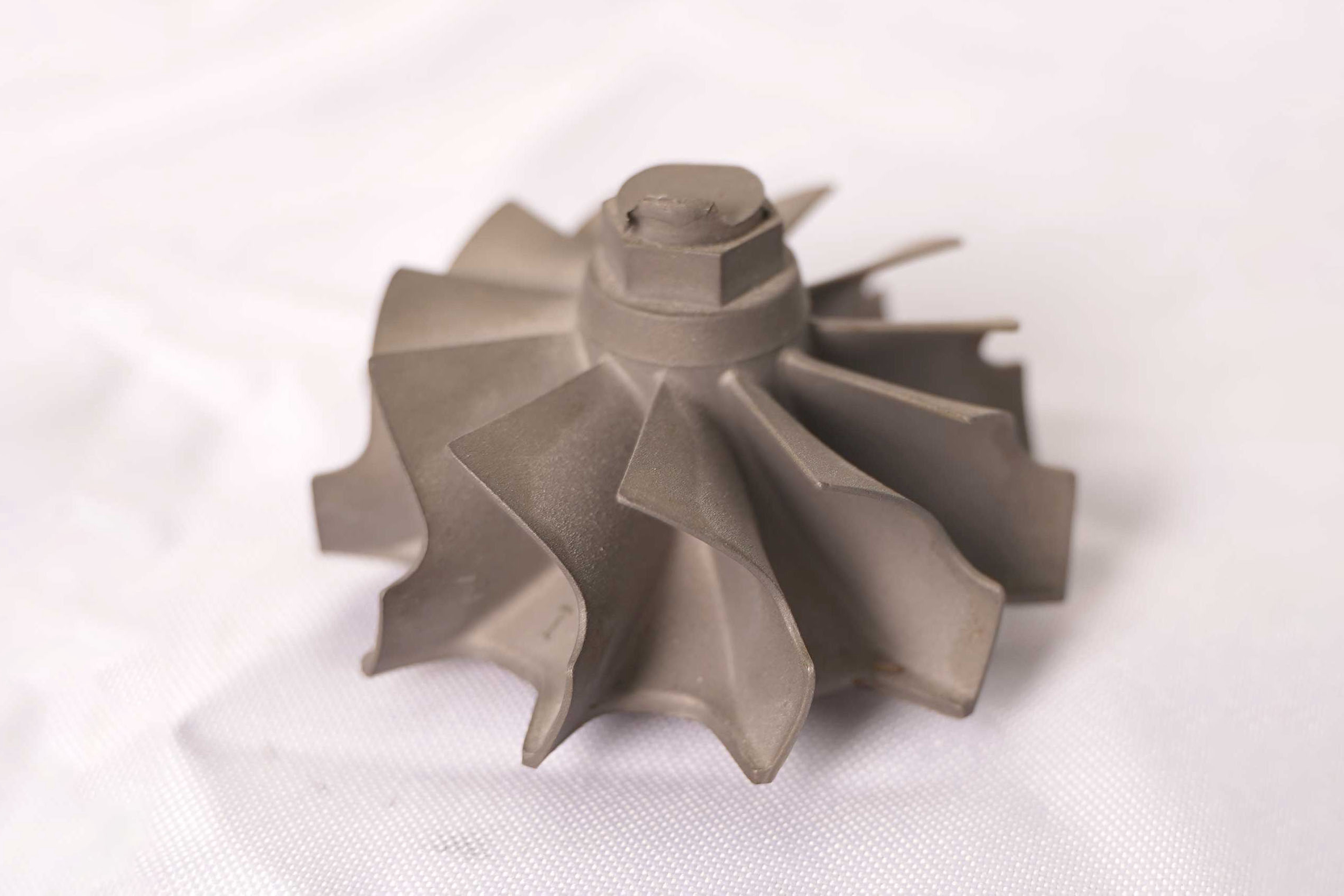

Ti-5Al-2.5Sn (Grade 6) is a near-alpha titanium alloy designed for excellent weldability, moderate strength, and outstanding creep resistance at temperatures up to 400°C. At our specialized lost wax casting foundry, we produce high-performance aircraft components from Ti-5Al-2.5Sn with ±0.05 mm dimensional precision and porosity levels below 1%, tailored to withstand demanding aerospace service environments.

Our vacuum-cast titanium parts are engineered for structural integrity and fatigue resistance across critical aerospace platforms, including fuselage frames, jet engine structures, and flight control hardware.

Core Technology: Lost Wax Casting of Ti-5Al-2.5Sn

We use vacuum investment casting to cast Ti-5Al-2.5Sn components into ceramic shell molds (8–10 layers). The alloy is melted and poured at ~1650°C under high vacuum (<10⁻³ torr), with mold preheating at ~1000°C. Controlled solidification (cooling rate: 30–70°C/min) ensures equiaxed grain structure (0.5–2 mm) and eliminates alpha-case formation on critical surfaces.

Material Characteristics of Ti-5Al-2.5Sn Alloy

Ti-5Al-2.5Sn (Grade 6) is a near-alpha titanium alloy with high specific strength, low density, and excellent thermal stability. It is widely used in aircraft structures where both mechanical reliability and temperature resistance are required. Key properties include:

Property | Value |

|---|---|

Density | 4.48 g/cm³ |

Ultimate Tensile Strength | ≥860 MPa |

Yield Strength | ≥790 MPa |

Elongation | ≥12% |

Operating Temperature Limit | ~400°C |

Creep Resistance | Excellent |

Weldability | Excellent |

Its creep resistance and oxidation stability make Ti-5Al-2.5Sn ideal for both primary and secondary aerospace structures operating at elevated temperatures.

Case Study: Ti-5Al-2.5Sn Aircraft Component Production

Project Background

An aerospace Tier-1 supplier required lightweight, thermally stable cast components for a high-altitude UAV engine mounting assembly. Ti-5Al-2.5Sn was selected for its superior weldability, elevated-temperature performance, and structural integrity. Our foundry delivered vacuum-cast parts conforming to AMS 4911 and ISO 9001 standards, with post-HIP porosity <1% and surface flatness within ±0.05 mm.

Typical High-Performance Aircraft Applications

Jet Engine Mount Assemblies: Ti-5Al-2.5Sn castings used in thrust frame lugs and supports due to their high fatigue strength and weldability.

Cabin Pressure Bulkhead Fittings: Precision-cast structural components that maintain integrity under pressure and temperature fluctuations at altitude.

Environmental Control System (ECS) Duct Supports: Cast supports and clamps exposed to heated airflow environments requiring oxidation stability and moderate creep resistance.

Rotorcraft Transmission Housings: Lightweight enclosures and brackets capable of long-term operation near 400°C under vibrational loading.

These components support thermal stability, weight reduction, and fatigue endurance in advanced aerospace platforms.

Aircraft Component Manufacturing Solutions

Casting Process High-purity wax patterns are invested into ceramic shells and vacuum cast at ~1650°C. Mold preheat and cooling parameters are strictly controlled to prevent shrinkage defects and alpha-case formation.

Post-processing After casting, Hot Isostatic Pressing (HIP) at ~920°C and 100 MPa reduces residual porosity. Solution heat treatment is applied for microstructural refinement and mechanical property optimization.

Post Machining Final features are machined using CNC equipment to achieve tight tolerances on mounting interfaces and seal surfaces. For complex geometries and thin-wall internals, EDM and deep hole drilling are used for feature access.

Surface Treatment To enhance fatigue and oxidation resistance, surfaces may be shot-peened and passivated. Titanium anodizing is optionally applied to reduce wear in sliding assemblies.

Testing and Inspection All parts are inspected via X-ray NDT, CMM dimensional scanning, mechanical property testing, and metallographic examination to verify phase distribution and grain control.

Core Manufacturing Challenges

Preventing alpha-case and oxidation during titanium melting and shell removal.

Holding ±0.05 mm tolerances on thin-walled aerospace bracket and flange geometries.

Ensuring long-term fatigue resistance under thermal cycling at 300–400°C.

Results and Verification

Dimensional precision within ±0.05 mm confirmed via 3D CMM analysis.

Porosity <1% achieved after HIP, verified by radiographic inspection.

Mechanical strength ≥860 MPa and elongation ≥12% validated at 300°C.

No phase transformation or oxidation degradation after 1000-hour thermal exposure.

FAQs

What makes Ti-5Al-2.5Sn suitable for high-temperature aerospace castings?

How is alpha-case formation controlled during the titanium casting process?

What surface finishes and coatings are recommended for Ti-5Al-2.5Sn parts?

Can your foundry produce custom aerospace castings for specific aircraft programs?

What quality assurance methods ensure flight-critical part compliance?