Superalloy Pipe Internal Channel Drilling Parts CNC Machining Service

Precision Fluid Flow Engineering in High-Temperature Alloys

In advanced energy systems and aerospace propulsion, internal channels in superalloy pipes are critical for coolant delivery, pressure equalization, and structural weight reduction. These channels must be precisely machined within complex geometries, often exceeding 15×D in depth, and operate under temperatures above 1000°C and pressures exceeding 500 bar.

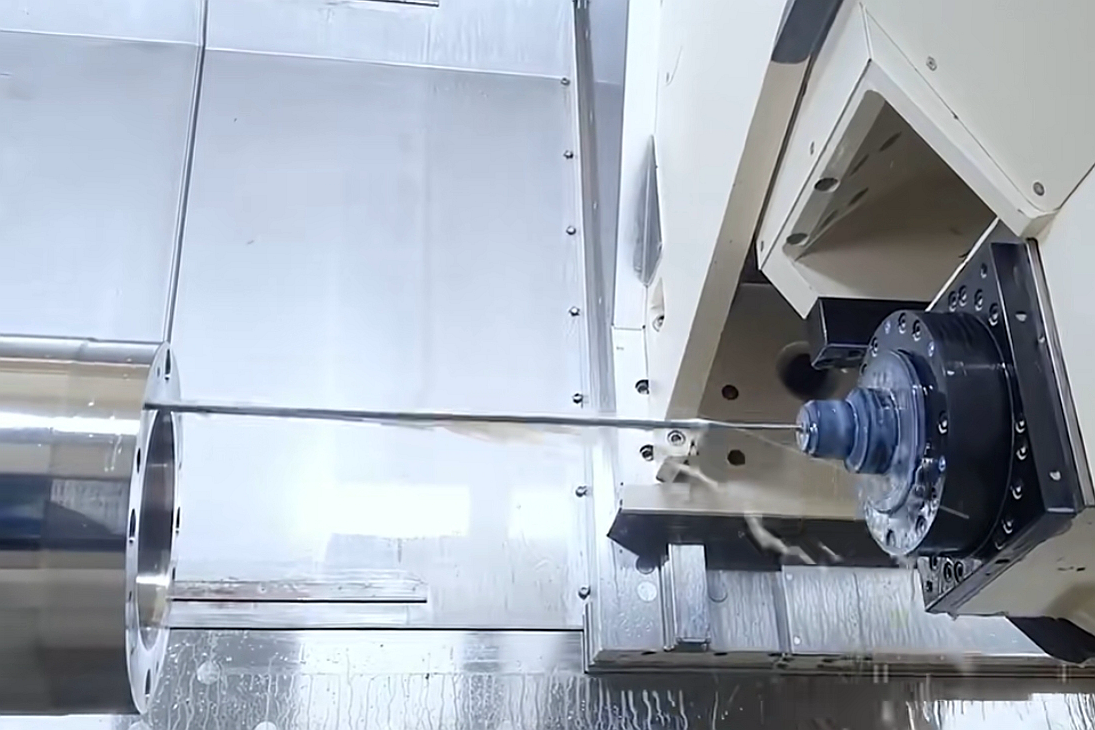

Neway AeroTech provides CNC machining and deep hole drilling services tailored for superalloy pipe parts, including internal fluid channels, cross-drilled features, and multi-axis coolant ports using alloys like Inconel 625, Hastelloy X, and Rene 41.

Core Technology in Superalloy Pipe Channel Machining

Neway AeroTech uses multi-axis CNC and EDM techniques to create internal channels with tight positional tolerances and surface quality requirements.

Deep hole drilling for bores >20×D

Cross-drilling and intersecting passages for pressure equalization

5-axis CNC milling for port features and entry face alignment

EDM slotting for high-precision through-wall connections

These processes ensure uniform flow paths, minimal pressure drop, and thermal fatigue resistance in hostile environments.

Typical Superalloy Materials for Pipe Channel Machining

Alloy | Max Temp (°C) | Yield Strength (MPa) | Key Applications |

|---|---|---|---|

980 | 827 | Cooling pipes, gas manifolds | |

1175 | 790 | Combustor ducts, pressure pipes | |

980 | 950 | Heat exchanger pipes, injection tubes | |

920 | 1265 | Aerospace fuel lines |

These materials are corrosion-resistant, weldable, and thermally stable for demanding channel geometries.

Case Study: CNC Machining of Inconel Pipe with Internal Coolant Network

Project Background

A client required a high-pressure Inconel 625 pipe with dual internal flow channels intersecting at 30° and 90°, extending over 600 mm. Tolerances included concentricity ≤ 0.008 mm, Ra 0.5 μm finish, and verified cross-channel fusion using X-ray inspection.

Typical Pipe Channel Component Models and Applications

Part Model | Description | Material | Channel Depth | Industry |

|---|---|---|---|---|

FCP-450 | Fuel conduit pipe with twin 22×D channels | Inconel 625 | 22×D | |

HXP-300 | Hastelloy pipe with spiral-cooling bores and radial vents | Hastelloy X | 16×D | |

RPC-600 | Reinforced pressure pipe with four angled inlets and boreholes | Rene 41 | 18×D | |

NMF-320 | Nimonic manifold pipe with micro-channel cross bores | Nimonic 90 | 10×D |

Each component supports thermal management and fluid transport under extreme operating conditions.

Machining Challenges for Internal Channel Superalloy Pipe Parts

Multi-axis channel convergence requires ±0.01 mm positional accuracy across all passages

Wall thinning in intersecting bores must be held >1.5 mm

Cross-channel detection requires internal non-destructive validation

Thermal distortion in thin-wall pipes must be controlled below 0.02 mm flatness

Surface finish of Ra ≤ 0.5 μm is critical to prevent flow disruption

CNC Solutions for Pipe Drilling and Channeling

Gun drilling and BTA systems for channel depths over 20×D with precision toolpath control

Angle boring with rotary axis compensation to align entry ports across complex pipe contours

Post-machining EDM cleaning of junctions to remove burrs and smooth intersections

Stress-relief heat treatment at 900–980°C for dimensional stability

CMM and X-ray testing to confirm alignment and through-hole continuity

Results and Verification

Manufacturing Methods

Parts were made from hot-forged blanks or vacuum investment castings, then machined using multi-axis CNC systems and deep hole drilling. Gun drills achieved channel diameters between 2–6 mm with depth control within ±0.01 mm.

Precision Finishing

Intersecting bores were polished to Ra 0.4 μm via EDM refinement. Threaded ports were milled to ISO 6g fit, and entry surfaces held flatness <0.01 mm to ensure sealing integrity.

Post-Processing

Each part underwent HIP followed by stress-relief heat treatment. Where required, TBC coatings were applied to outer walls, and passivation ensured corrosion resistance post-EDM.

Inspection

CMM confirmed channel position accuracy within ±0.006 mm. X-ray verified full channel continuity. SEM validated bore edge quality and confirmed that no cracking or burn marks remained.

FAQs

What is the maximum channel depth achievable in superalloy pipes?

How do you inspect intersecting internal bores without damaging the part?

Can angled channels be machined with positional tolerances under 10 μm?

What materials are best for high-temperature pipe channel applications?

How do coatings and passivation affect channel roughness and flow?