Nimonic 81 Superalloy Casting Marine Propulsion Systems Workshop

Introduction

Nimonic 81 is a nickel-chromium alloy strengthened with titanium and aluminum, offering exceptional high-temperature strength, oxidation resistance, and superior corrosion resistance in saline environments. As a dedicated superalloy casting workshop, we produce precision Nimonic 81 components for marine propulsion systems, meeting tight tolerances (±0.05 mm) and porosity control below 1%.

Our Nimonic 81 castings are engineered for demanding marine propulsion environments, including propeller hubs, turbine nozzles, and exhaust modules operating under sustained mechanical and thermal stress.

Core Technology: Superalloy Casting of Nimonic 81

We utilize advanced vacuum investment casting to produce Nimonic 81 marine propulsion components. Ceramic shell molds (8–10 layers) are used, and the alloy is melted at ~1360°C and poured under vacuum. Mold preheating at 1050°C and controlled solidification (cooling rate: 40–90°C/min) ensure grain size of 0.5–2 mm and dimensional precision of ±0.05 mm.

Material Characteristics of Nimonic 81 Alloy

Nimonic 81 is optimized for applications involving both high-temperature mechanical stress and aggressive saltwater exposure. Key properties include:

Property | Value |

|---|---|

Melting Range | 1320–1380°C |

Density | 8.2 g/cm³ |

Tensile Strength (at 750°C) | ≥800 MPa |

Yield Strength (at 750°C) | ≥600 MPa |

Elongation | ≥25% |

Oxidation Resistance | Excellent up to 950°C |

Corrosion Resistance | Excellent in marine environments |

These characteristics make Nimonic 81 suitable for high-performance marine propulsion applications requiring durability, saltwater resistance, and thermal stability.

Case Study: Nimonic 81 Marine Propulsion Castings

Project Background

A naval propulsion contractor required durable alloy components for high-efficiency gas turbine exhaust systems and mechanical coupling assemblies in a marine environment. Our workshop provided Nimonic 81 castings with fine-grain control and vacuum integrity, meeting ISO 9001 and MIL-STD casting standards for naval machinery components.

Typical Marine Propulsion Applications

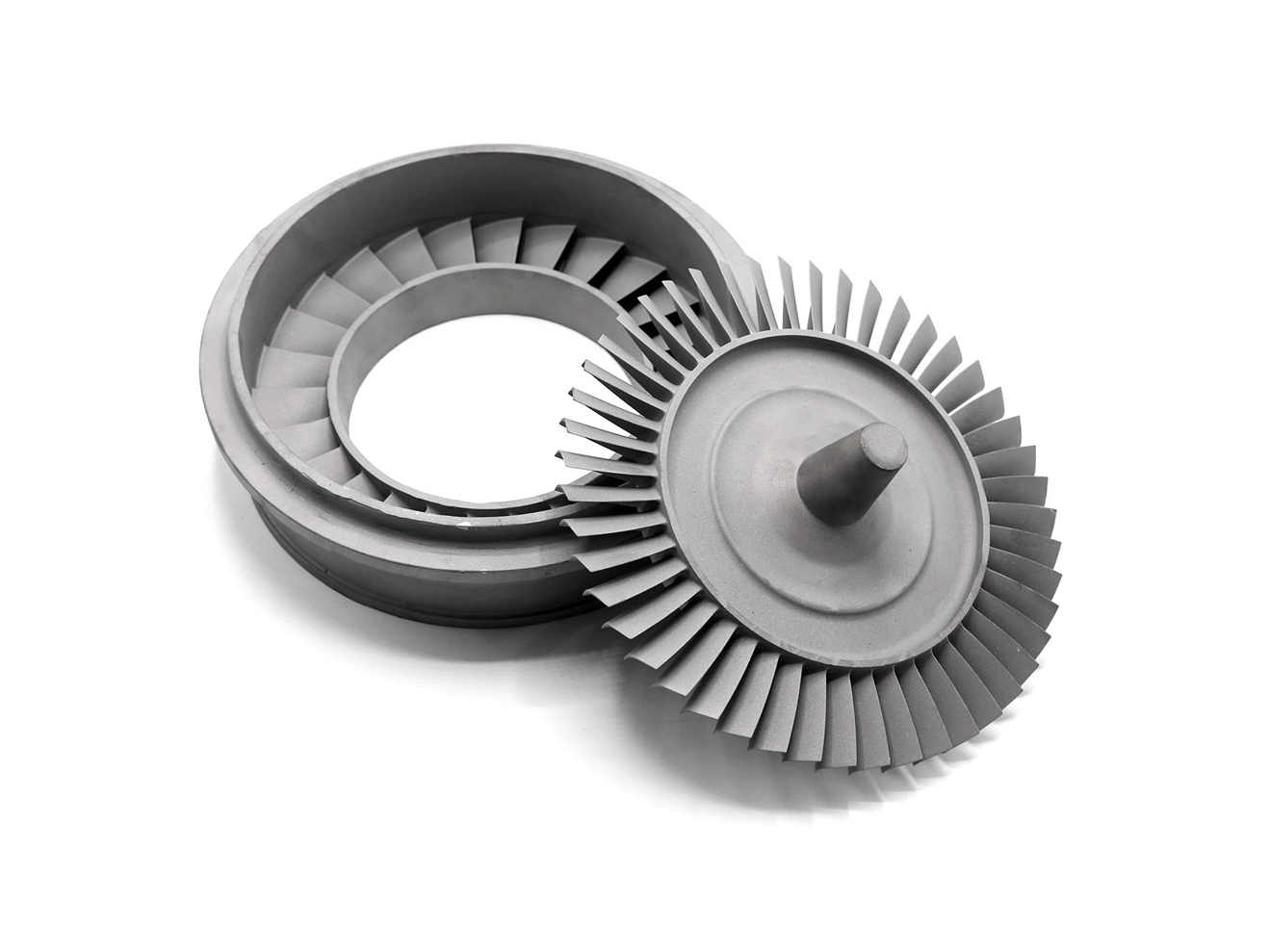

Waterjet Impeller Hubs: Nimonic 81 cast impeller hubs offering erosion and corrosion resistance in high-speed water flow conditions.

Exhaust Diffuser Segments: Components exposed to high exhaust temperatures and saline condensation; Nimonic 81 resists thermal oxidation and surface corrosion.

Gas Turbine Nozzle Guide Vanes: Precision-cast parts maintaining mechanical integrity and surface profile under cyclic temperature fluctuations up to 950°C.

Propulsion Coupling Rings: Static mechanical connectors between turbine output shafts and marine propulsors, designed for stress endurance and dimensional accuracy.

These applications highlight the alloy’s value in propulsion reliability, corrosion resistance, and fatigue endurance in marine engine rooms and gas path systems.

Marine Component Manufacturing Solutions

Casting Process Wax patterns are invested in ceramic shells and cast under vacuum at ~1360°C. Controlled solidification ensures uniform carbide distribution and minimal shrinkage. Thin-wall sections are cast with tight tolerances, critical for dynamic balancing in rotors.

Post-processing Hot Isostatic Pressing (HIP) at 1180°C and 100 MPa is applied to remove porosity. CNC machining finalizes bolt patterns, sealing grooves, and interfacing surfaces.

Surface Treatment Components may be treated with oxidation-resistant aluminide or ceramic coatings for extended thermal fatigue life in turbine zones. Seawater-exposed parts can be passivated or coated with marine-grade barrier systems.

Testing and Inspection All parts are inspected with X-ray radiography, CMM measurements, and elevated-temperature tensile testing. Metallography confirms phase distribution and grain consistency.

Core Manufacturing Challenges of Marine Nimonic 81 Components

Achieving dimensional accuracy for rotating assemblies (±0.05 mm) while managing alloy shrinkage and distortion during cooling.

Ensuring seawater corrosion resistance over 20,000+ operational hours.

Maintaining grain refinement in thick-wall, thermally loaded castings for fatigue resistance.

Results and Verification

Final components maintained dimensional tolerance within ±0.05 mm, verified by 3D CMM scanning.

X-ray testing confirmed internal porosity <1% after HIP.

Surface oxidation and salt-spray resistance verified after 1000-hour marine exposure testing.

Elevated-temperature tensile strength ≥800 MPa consistently achieved at 750°C.

FAQs

Why is Nimonic 81 suitable for marine propulsion applications?

What casting tolerances are achievable for rotating marine parts?

How does Nimonic 81 perform in seawater and high-temperature zones?

Can your workshop customize castings for naval propulsion system retrofits?

What quality certifications and testing protocols do you follow for marine parts?