Equiaxed Casting Superalloy Turbine Blades Welding Manufacturer

Expert Welding of Equiaxed Superalloy Turbine Blades for Hot Section Performance

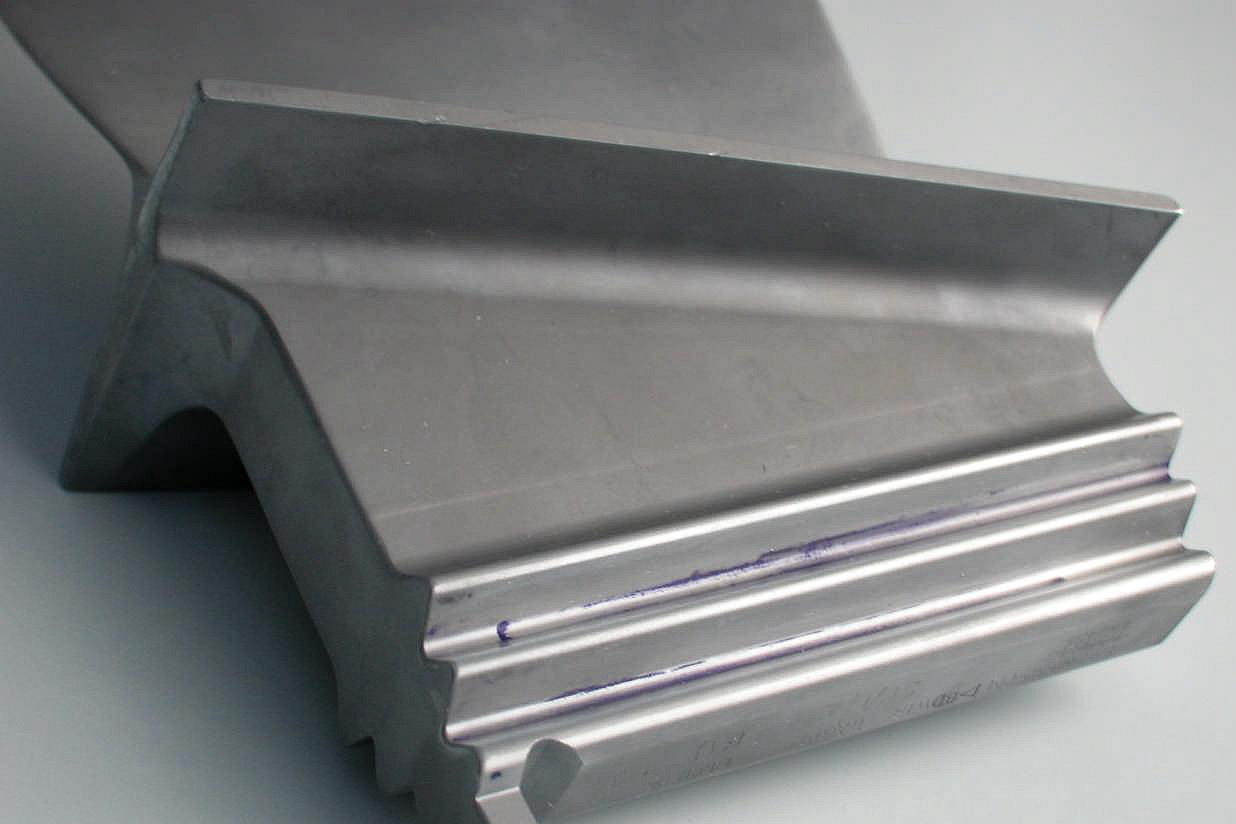

Equiaxed superalloy turbine blades are commonly used in industrial and power-generation gas turbines due to their robust isotropic mechanical properties and relatively lower cost compared to directionally solidified or single crystal variants. However, these castings—particularly those made from Inconel, Rene alloys, and Hastelloy—require expert welding techniques to avoid cracking, distortion, and property degradation due to their complex gamma prime microstructure and casting porosity.

Neway AeroTech is a professional superalloy welding manufacturer offering TIG and laser welding services for equiaxed-cast turbine blades used in power generation, aerospace, and energy systems. Services include tip repair, edge buildup, surface restoration, and OEM-compliant weld integration.

Welding Technologies for Equiaxed-Cast Superalloy Blades

Our workshop is equipped with advanced systems to perform reliable welds on thermally and mechanically stressed equiaxed blades.

TIG welding using Inconel, Rene, and Hastelloy-matched fillers

Laser welding for thin trailing edge and low-distortion applications

Vacuum shielding chambers for oxidation-sensitive weld zones

Post-weld heat treatment to restore phase balance and hardness

All processes are supported by AS9100D, NADCAP, and OEM turbine blade specifications.

Common Superalloy Grades Used in Blade Welding

Alloy | Max Temp (°C) | Yield Strength (MPa) | Typical Blade Application |

|---|---|---|---|

1050 | 880 | Industrial turbine blades | |

1040 | 960 | Vane rings, rotor blades | |

1175 | 790 | Guide vanes, exhaust blades | |

950 | 760 | Turbine wheel blades |

These alloys are cast using equiaxed methods for isotropic strength and weldability.

Case Study: Rene 77 Equiaxed Blade Tip TIG Weld Repair

Project Background

A client operating 50 MW gas turbines required weld repair on Rene 77 equiaxed blades that exhibited tip cracking and erosion. TIG welding was performed with matched filler, followed by heat treatment at 980°C and X-ray testing to confirm full fusion and defect-free repair.

Typical Welded Blade Types and Industries

Blade Model | Description | Alloy | Industry |

|---|---|---|---|

TBR-720 | High-pressure turbine blade with 2 mm TIG tip buildup | Inconel 738 | |

VNS-500 | Vane segment with laser seam weld at trailing edge | Hastelloy X | |

RBX-860 | Rotor blade edge restoration with TIG weld and root profiling | Rene 77 | |

STX-330 | Stator blade with shroud seam weld and CMM finish validation | Inconel 713C |

All welds are tested for thermal fatigue life and high-cycle durability.

Welding Challenges in Equiaxed Turbine Blade Repairs

Liquation cracking risk increases when interpass temperature exceeds 175°C in gamma prime-rich equiaxed alloys like Inconel 738 or Rene 77.

HAZ hardness over 420 HV forms if cooling rate is uncontrolled during blade edge or trailing welds.

Oxidation occurs above 500 ppm oxygen in TIG arcs, causing porosity and alpha case in weld pool surface.

Weld distortion exceeds 0.02 mm in thin trailing edges without restraint or preheat for equiaxed blade sections.

Residual stress retention >250 MPa leads to warping post-machining if heat treatment isn’t properly applied after welding.

Welding Process Solutions for Superalloy Blades

Glovebox welding with O₂ < 50 ppm eliminates oxide inclusions and ensures full fusion on trailing edge and tip welds.

Interpass temperatures ≤ 150°C maintained using thermal sensors to minimize gamma prime liquation and grain boundary cracking risks.

TIG welding with ERNiCrMo-3 filler matches chemistry and retains ductility under thermal fatigue up to 1050°C service temperature.

Post-weld heat treatment at 980°C relieves residual stress and homogenizes grain structure within the heat-affected zone.

HIP at 1030°C, 100 MPa for 4 hours closes internal porosity and restores fatigue strength of cast equiaxed blade repairs.

Results and Verification

Welding Execution

TIG welding was applied using matched Rene 77 filler under argon shielding. Weld buildup restored blade length within ±0.01 mm tolerance.

Post-Weld Processing

Blades underwent stress relief heat treatment at 980°C for 2 hours, followed by optional HIP at 1030°C, 100 MPa to eliminate subsurface voids.

Inspection

X-ray inspection verified weld continuity. CMM confirmed airfoil profile within ±0.008 mm. SEM analysis showed full grain fusion without secondary phase defects.

FAQs

What Rene and Inconel alloys are suitable for equiaxed blade welding?

What heat treatment is used after turbine blade welding?

Can thin trailing edges be laser welded without distortion?

How do you inspect welded turbine blades?

Do you offer coating after blade weld repair?