Carbon Steel Tailor-Made Oil and Gas Components 3D Printing

Introduction to Carbon Steel Additive Manufacturing for Oil and Gas Applications

Carbon steel remains one of the most widely used materials in oil and gas due to its strength, machinability, and cost-effectiveness. With 3D printing, carbon steel components can now be manufactured on demand with complex geometries, optimized flow paths, and reduced lead times—making it a strong fit for tooling, connectors, flanges, and enclosures in demanding field environments.

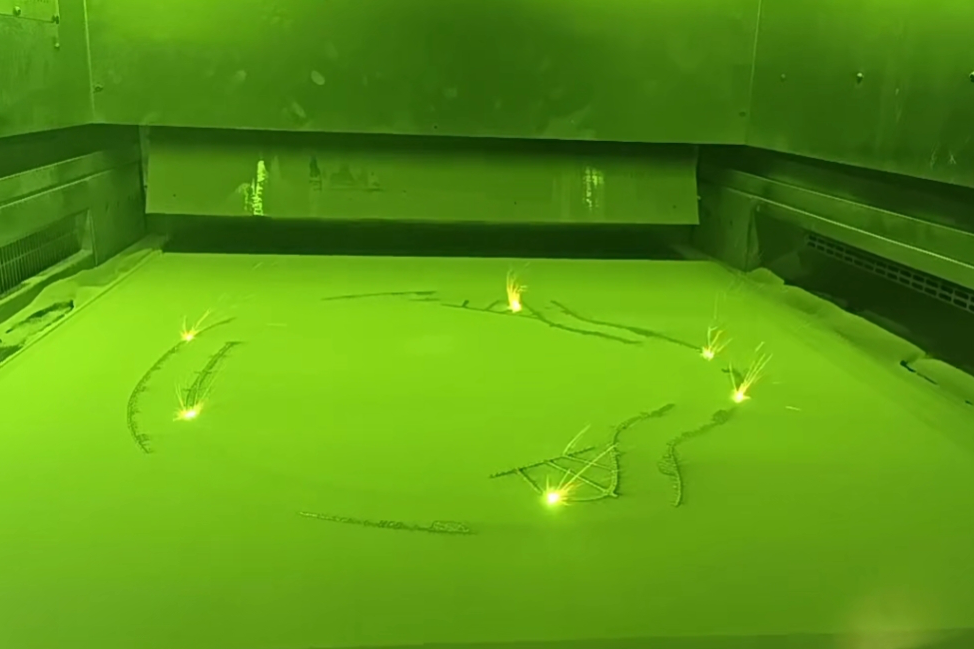

At Neway Aerotech, our carbon steel 3D printing services offer precision manufacturing of tailor-made parts for the upstream, midstream, and downstream sectors using Directed Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM).

Additive Manufacturing Technologies for Carbon Steel Components

Process Overview

Technology | Deposition Rate | Feature Resolution | Common Use Cases |

|---|---|---|---|

DED | 10–30 cm³/h | ±0.5 mm | Pump bodies, tool repair, casing sections |

WAAM | 1–4 kg/h | ±0.3 mm | Structural joints, pipeline flanges, skids |

DED is ideal for small-to-medium parts; WAAM supports large structures and pipe-grade builds.

Why Carbon Steel is Suited for Oil and Gas Applications

Property | Value | Field Benefit |

|---|---|---|

Yield Strength | 250–500 MPa | Withstands drilling and structural loads |

Weldability | Excellent | Supports hybrid or repair applications |

Corrosion Resistance | Moderate with coatings | Can be treated for sour service |

Thermal Conductivity | ~50 W/m·K | Useful for thermal transfer components |

Cost Efficiency | High | Reduces material waste and total project cost |

Post-Processing and Surface Finishing Strategy

Heat Treatment: Normalizing or quenching to improve toughness and wear resistance.

CNC Machining: Applied to sealing surfaces, threads, and mating flanges.

Coatings:

Epoxy or zinc-rich paint for external corrosion resistance.

Nitriding or carburizing for surface hardening.

Testing: Dimensional CMM inspection and pressure testing for functional features.

Case Study: Custom Carbon Steel Valve Body for Oilfield Skid System

Project Background

An upstream oilfield client required a replacement valve body with revised port orientation for a skid-mounted fluid control system. Lead time and geometric complexity made traditional casting and machining infeasible.

Manufacturing Workflow

Design: STL model included internal flow path realignment and angled outlet geometry.

Material: ASTM A216-grade carbon steel wire, Ø1.6 mm for WAAM.

Printing: WAAM deposition on robotic arm, build time 6 hours.

Post-Processing:

Heat treated at 880°C for 2 hours.

Machined mounting faces and threads to ±0.02 mm.

NDT using ultrasonic inspection and dye penetrant testing.

Final Testing: Hydrostatic tested to 2× service pressure (32 bar).

Results and Verification

The printed carbon steel valve body met all functional criteria, reducing lead time from 5 weeks to 6 days. The printed geometry improved flow efficiency by 12%, and the component passed all pressure and dimensional validation tests without failure.

FAQs

Can 3D printed carbon steel components handle sour service conditions in oilfields?

What are the post-treatment options to improve corrosion resistance?

Is WAAM suitable for large bore pipe fittings and flanges?

Can legacy carbon steel components be repaired using additive manufacturing?

What is the turnaround time for custom carbon steel additive parts?