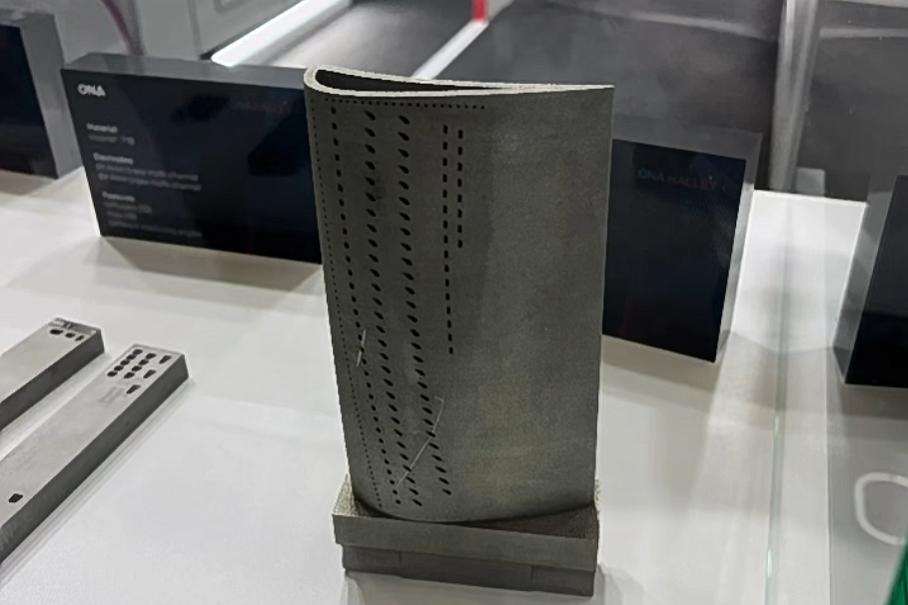

Superalloy Inconel 718 3D Printed Turbine Blade Advanced EDM Fabrication

Introduction to EDM Finishing for 3D Printed Inconel 718 Turbine Blades

Inconel 718 turbine blades produced via 3D printing require advanced EDM finishing to meet precision geometry and thermal fatigue resistance standards. Electro-discharge machining enables micro-feature refinement, internal cavity access, and final tolerance control in additive-manufactured superalloy airfoils.

At Neway Aerotech, we combine 3D printing of Inconel 718 with advanced EDM processing to deliver high-integrity turbine blades for power generation and aerospace propulsion systems.

EDM Machining Technology Overview

Classification of EDM Machining

EDM Process | Surface Roughness (Ra, μm) | Dimensional Tolerance (mm) | Aspect Ratio | Heat Affected Zone (HAZ, μm) | Min. Feature Size (mm) |

|---|---|---|---|---|---|

Wire EDM | 0.3–1.2 | ±0.002–±0.01 | Up to 20:1 | 2–5 μm | ~0.1 |

Sinker EDM | 0.4–2.5 | ±0.005–±0.02 | Up to 10:1 | 5–10 μm | ~0.2 |

Hole Drilling EDM | 0.5–3.0 | ±0.02–±0.05 | Up to 30:1 | 10–15 μm | ~0.1 |

Micro-EDM | 0.1–0.4 | ±0.001–±0.005 | Up to 15:1 | <2 μm | <0.05 |

EDM complements additive manufacturing by achieving ultra-fine finishes and complex cavity geometries unachievable through laser fusion alone.

EDM Machining Selection Strategy

Wire EDM: Ideal for airfoil edge finishing, tip trimming, and trailing edge definition.

Sinker EDM: Used for root form cavities, attachment grooves, and locking features.

Hole Drilling EDM: Applied to internal film cooling holes and exit ports.

Micro-EDM: Enables <0.2 mm bleed holes and micro-notches in gas path areas.

Material Considerations

Inconel 718 Properties in 3D Printed Blades

Property | Value |

|---|---|

Yield Strength @ 650°C | ~970 MPa |

Hardness (after HIP + Aging) | HRC 36–42 |

Max Service Temperature | 700–750°C |

Oxidation Resistance | Excellent for turbine environments |

3D Printing Compatibility | Proven in SLM additive processes |

Why EDM Is Critical for 3D Printed Inconel 718 Blades

Refines surface roughness inside lattice and cooling passages

Removes residual powder traps and recast zones

Enables post-print customization of complex external features

Minimizes HAZ and preserves structural integrity in thin sections

Case Study: EDM Post-Processing of In718 3D Printed Turbine Blade

Project Background

A customer in the power generation industry required high-precision post-processing for a 3D printed Inconel 718 turbine blade featuring internal lattice structures and 54 film cooling holes.

Manufacturing Work Flow

3D Printing: SLM additive manufacturing used to build blade layer by layer, 40 μm thickness, density >99.7%

HIP Treatment: Hot Isostatic Pressing at 1200°C, 100 MPa for 4 hours

Wire EDM: Edge trimming and tip shaping with ±0.005 mm accuracy

Hole EDM: Film cooling holes (Ø0.6 mm) machined at 20:1 aspect ratio

Sinker EDM: Root attachment pocket depth 10 mm, tolerance ±0.005 mm

Post Process

Stress-relief heat treatment at 925°C for 2 hours

Shot peening to enhance fatigue life (>25% improvement)

Final passivation to remove EDM debris and improve corrosion resistance

Surface Finishing

Internal surfaces polished to Ra ≤ 0.6 μm in film hole outlets

Airfoil tip radius controlled to R0.05 mm

No microburrs or crack indicators after SEM inspection

Inspection

CMM on 72 key points with <2 μm deviation

X-ray NDT confirmed internal channel integrity

Ultrasonic immersion testing verified full pore closure

Pressure test on film holes: 0.8 MPa air flow, <2% variation across all ports

Results and Verification

EDM finishing delivered ±0.003 mm dimensional accuracy and consistent geometry across complex 3D printed turbine blade profiles.

All 54 film cooling holes met flow uniformity and Ra ≤ 0.6 μm requirement, enabling optimized thermal management.

SEM and CMM results showed zero cracking, deformation, or dimensional drift from original CAD after EDM post-processing.

Final blade passed 1000-hour thermal endurance simulation and >3000 on-off cycles without fatigue-related failures.

The client approved EDM + 3D print combination for serial turbine blade production after this successful pilot.

FAQs

Can EDM refine internal cooling passages in 3D printed turbine blades?

What dimensional tolerances are realistic with EDM after metal printing?

Is EDM compatible with lattice and support-free blade structures?

How does EDM affect surface fatigue resistance in additive parts?

What are the ideal post-processing steps after EDM on printed In718 blades?