High-temperature alloys Precision Forging high-stress fittings

Introduction

Precision forging of high-temperature alloys is essential for manufacturing high-stress fittings that must endure extreme mechanical loads, corrosive fluids, and elevated temperatures. At Neway AeroTech, we forge nickel- and cobalt-based superalloys—including Inconel 718, Hastelloy X, and Rene 41—into components such as flanges, elbows, tees, and coupling fittings for use in chemical processing, power generation, and aerospace systems.

Our forged fittings deliver superior grain flow, high yield strength (>900 MPa), and excellent dimensional accuracy (±0.02 mm), ensuring leak-tight performance and resistance to creep, fatigue, and oxidation even above 700°C.

Core Technology of Precision Forging High-Stress Fittings

Billet Selection and Heating: Superalloy ingots (e.g., Inconel, Hastelloy) are preheated to forging temperatures between 1050–1150°C for optimal flow and microstructure refinement.

Closed-Die Forging: Fittings are formed under high pressure in custom die sets, aligning grain flow with stress paths to enhance fatigue and creep resistance.

Grain Structure Control: Grain size controlled to ASTM 10–12 with directional orientation to prevent failure in threaded or welded joints.

Heat Treatment: Solution and aging treatment enhances mechanical properties and restores phase balance post-forging.

Precision CNC Machining: Final machining on multi-axis CNC equipment achieves ±0.02 mm tolerances on sealing faces, threads, and bores.

Surface Treatment (Optional): Passivation, nitriding, or coating processes applied to improve corrosion resistance and reduce galling.

Material Characteristics of Forged Superalloy Fittings

Alloy | Max Operating Temp | Yield Strength | Oxidation Resistance | Common Applications |

|---|---|---|---|---|

Inconel 718 | 700°C | ≥1000 MPa | Excellent | Power plant steam lines, aerospace valves |

Hastelloy X | 1100°C | ≥690 MPa | Excellent | Combustion systems, chemical reactors |

Rene 41 | 980°C | ≥900 MPa | Very High | Jet engine casings, high-pressure piping |

Case Study: Forged Inconel 718 High-Pressure Couplings for Aerospace Fuel Lines

Project Background

An aerospace OEM required high-pressure fittings for a jet engine fuel delivery system. The fittings needed to withstand 400 bar internal pressure, operate above 650°C, and maintain dimensional integrity after 50,000 thermal cycles. Inconel 718 was selected and forged to shape with minimal post-machining.

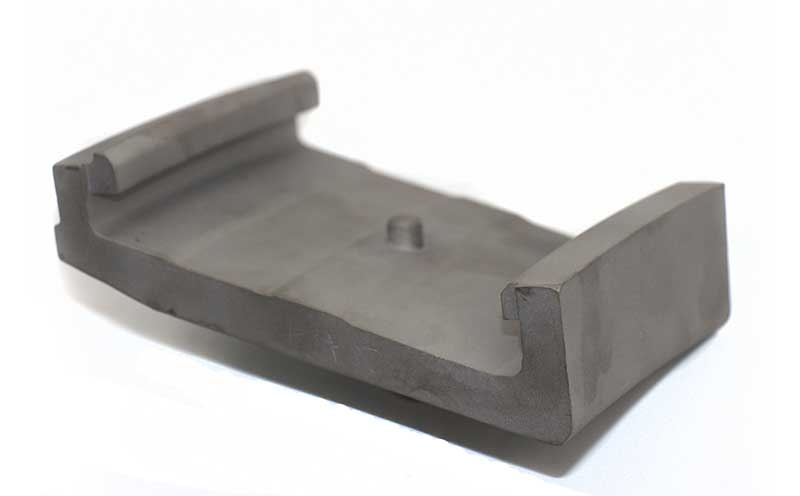

Typical Forged High-Stress Fittings

Weld Neck Flanges (Hastelloy X): Forged for high-pressure chemical service with superior oxidation and pitting resistance.

Elbows and Bends (Inconel 718): Provide tight-radius flow direction in high-velocity steam or fuel lines, resisting thermal fatigue.

Threaded Couplings (Rene 41): Used in jet engine assemblies and pressure vessels, combining strength and thermal creep resistance.

Reducers and Tees: Custom forged transitions used in turbine exhaust and power piping, ensuring crack-free weldability.

Forging and Finishing Solution

Billet Preparation: Alloys cut to size and heated to 1100°C in controlled-atmosphere furnaces to minimize oxidation.

Precision Closed-Die Forging: Forging performed on hydraulic presses using dies tailored to part geometry and stress profiles.

Trimming and Pre-Machining: Flash removed and surfaces machined to <2 mm finish allowance before heat treatment.

Heat Treatment: Components solution-treated and aged per alloy-specific specs (e.g., Inconel 718: 980°C solution + 720°C aging).

CNC Machining: All sealing surfaces, threads, and complex ports machined to ±0.02 mm using CNC systems.

Surface Finishing: Parts polished to Ra <1.6 µm or passivated based on application-specific corrosion requirements.

Inspection: X-ray and ultrasonic testing confirm internal quality; CMM inspection verifies geometry.

Results and Validation

Mechanical Properties: Inconel 718 fittings exceeded 1000 MPa yield strength with 1450 MPa UTS after aging.

Pressure Testing: Hydrostatic burst testing passed 1.5x rated pressure without leakage or deformation.

Thermal Cycling:

50,000 cycles between 150–650°C completed without thread relaxation or dimensional shift.

Dimensional Accuracy: Machined features held within ±0.02 mm; sealing faces flatness <0.01 mm confirmed by CMM.

Surface and Corrosion Resistance: No degradation after 1000-hour salt spray test or nitric acid immersion (per ASTM G48).

FAQs

What are the advantages of precision forging over casting for high-stress fittings?

Which high-temperature alloys are most commonly used in precision forged couplings and flanges?

What is the typical lead time for custom forged Inconel or Hastelloy fittings?

Can forged fittings be supplied with threaded, flanged, or socket-weld ends?

What NDT and dimensional testing methods does Neway AeroTech use to verify quality?